Preparation method of clothes prism structure

A technology for prisms and clothing, which is applied in the field of preparation of clothing prism structures, can solve the problems of losing the sense of depth and three-dimensionality, and achieve the effects of environmental friendliness, simple operation, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

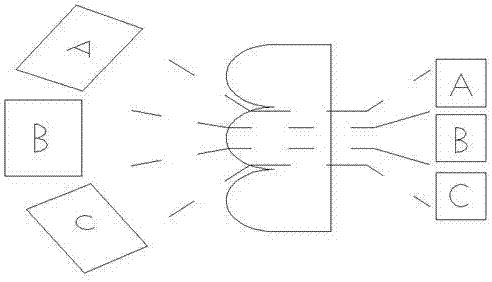

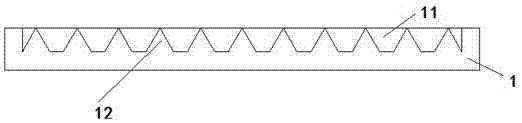

[0031] A patterned product with a prism effect, characterized in that it includes a symmetrically arranged arc surface, the arc surface includes an A surface, a B surface, and a C surface, and the B surface is arranged on one side of the A surface. The C surface is arranged on the other side of the A surface, and the A surface, the B surface, and the C surface are integrally connected.

[0032] Further, the radian of the A surface is 2 / 3π.

[0033] Further, the arc of the B surface is 2 / 3π.

[0034] Further, the radian of the C surface is 2 / 3π.

[0035] A kind of preparation method of clothing prism structure is characterized in that, comprises the following steps:

[0036] S1. Pretreatment: Align and place processed products, hot stamping glue, and non-woven fabrics to the hot stamping machine processing platform in sequence for hot stamping treatment;

[0037] S2. Silk screen processing: Position the processed product on the worktable, place the screen printing template f...

Embodiment 2

[0055] A patterned product with a prism effect, characterized in that it includes a symmetrically arranged arc surface, the arc surface includes an A surface, a B surface, and a C surface, and the B surface is arranged on one side of the A surface. The C surface is arranged on the other side of the A surface, and the A surface, the B surface, and the C surface are integrally connected.

[0056] Further, the radian of the A surface is 5 / 6π.

[0057] Further, the arc of the B surface is 5 / 6π.

[0058] Further, the radian of the C surface is 5 / 6π.

[0059] A kind of preparation method of clothing prism structure is characterized in that, comprises the following steps:

[0060] S1. Pretreatment: Align and place processed products, hot stamping glue, and non-woven fabrics to the hot stamping machine processing platform in sequence for hot stamping treatment;

[0061] S2. Silk screen processing: Position the processed product on the worktable, place the screen printing template f...

Embodiment 3

[0075] A patterned product with a prism effect, characterized in that it includes a symmetrically arranged arc surface, the arc surface includes an A surface, a B surface, and a C surface, and the B surface is arranged on one side of the A surface. The C surface is arranged on the other side of the A surface, and the A surface, the B surface, and the C surface are integrally connected.

[0076] Further, the radian of the A surface is 3 / 4π.

[0077] Further, the arc of the B surface is 3 / 4π.

[0078] Further, the radian of the C surface is 3 / 4π.

[0079] A kind of preparation method of clothing prism structure is characterized in that, comprises the following steps:

[0080] S1. Pretreatment: Align and place processed products, hot stamping glue, and non-woven fabrics to the hot stamping machine processing platform in sequence for hot stamping treatment;

[0081] S2. Silk screen processing: Position the processed product on the worktable, place the screen printing template f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com