Manufacturing die for 3225 Kovar ring

A technology for manufacturing molds and molds, applied in the field of 3225 Kovar ring manufacturing molds, to achieve the effect of improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

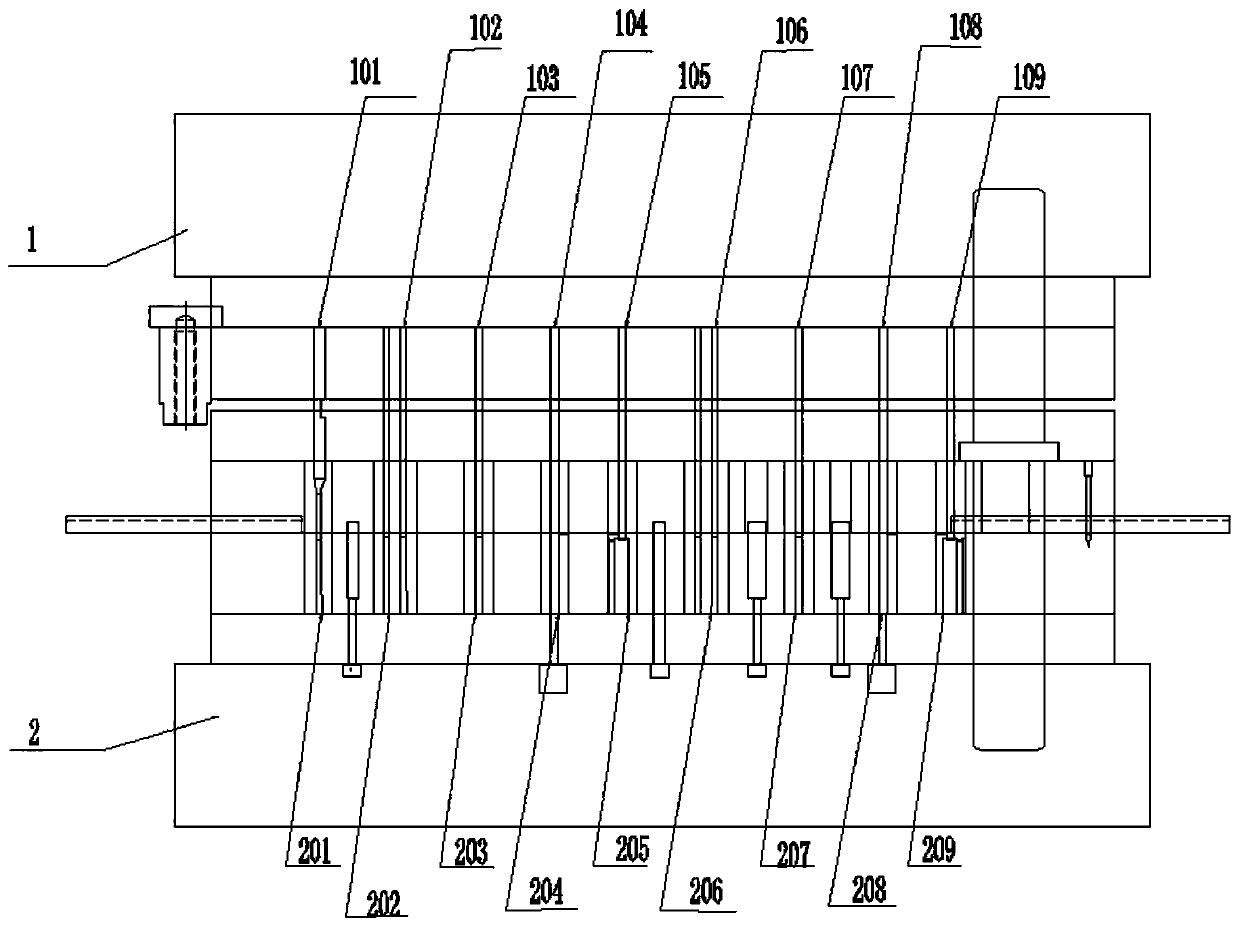

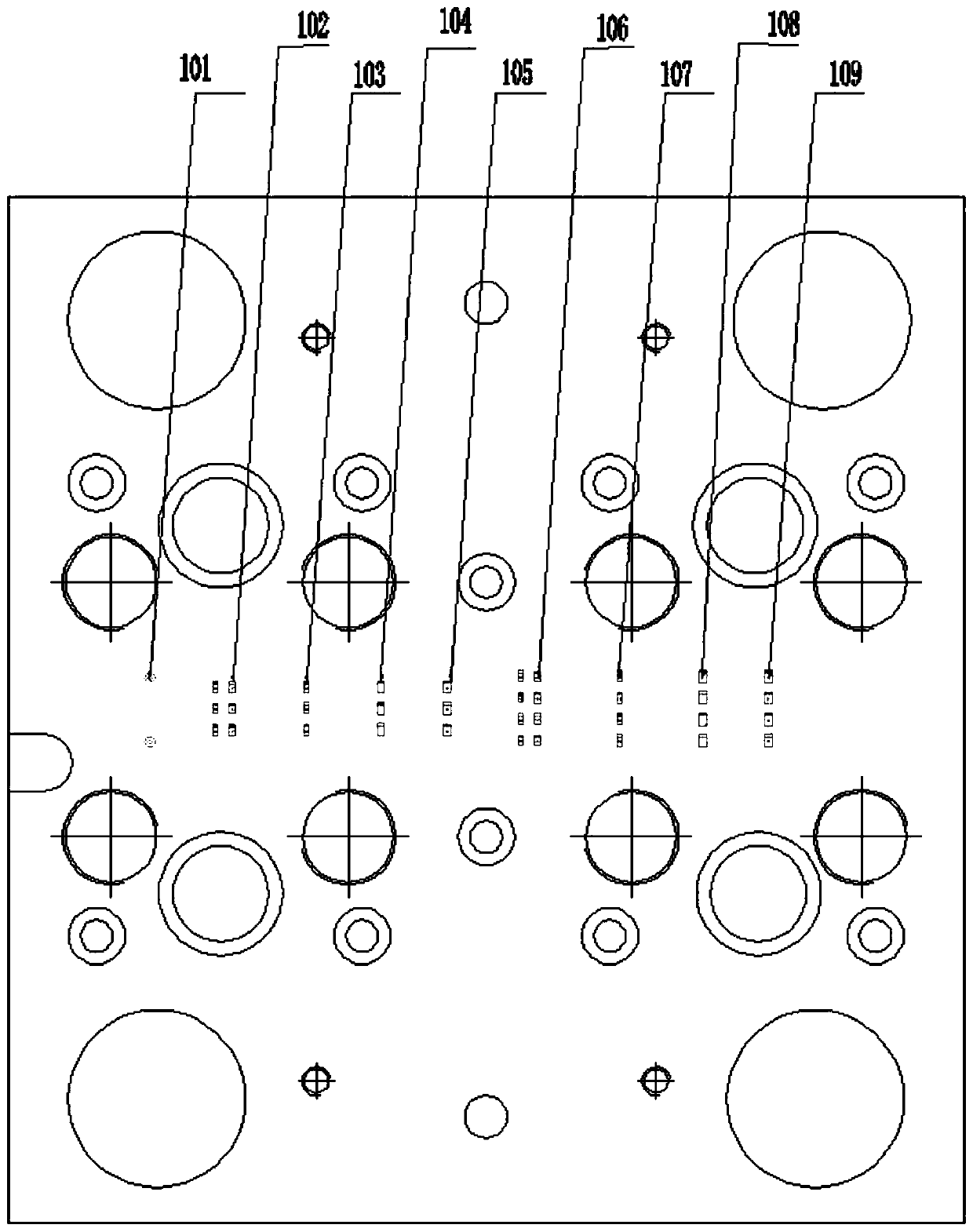

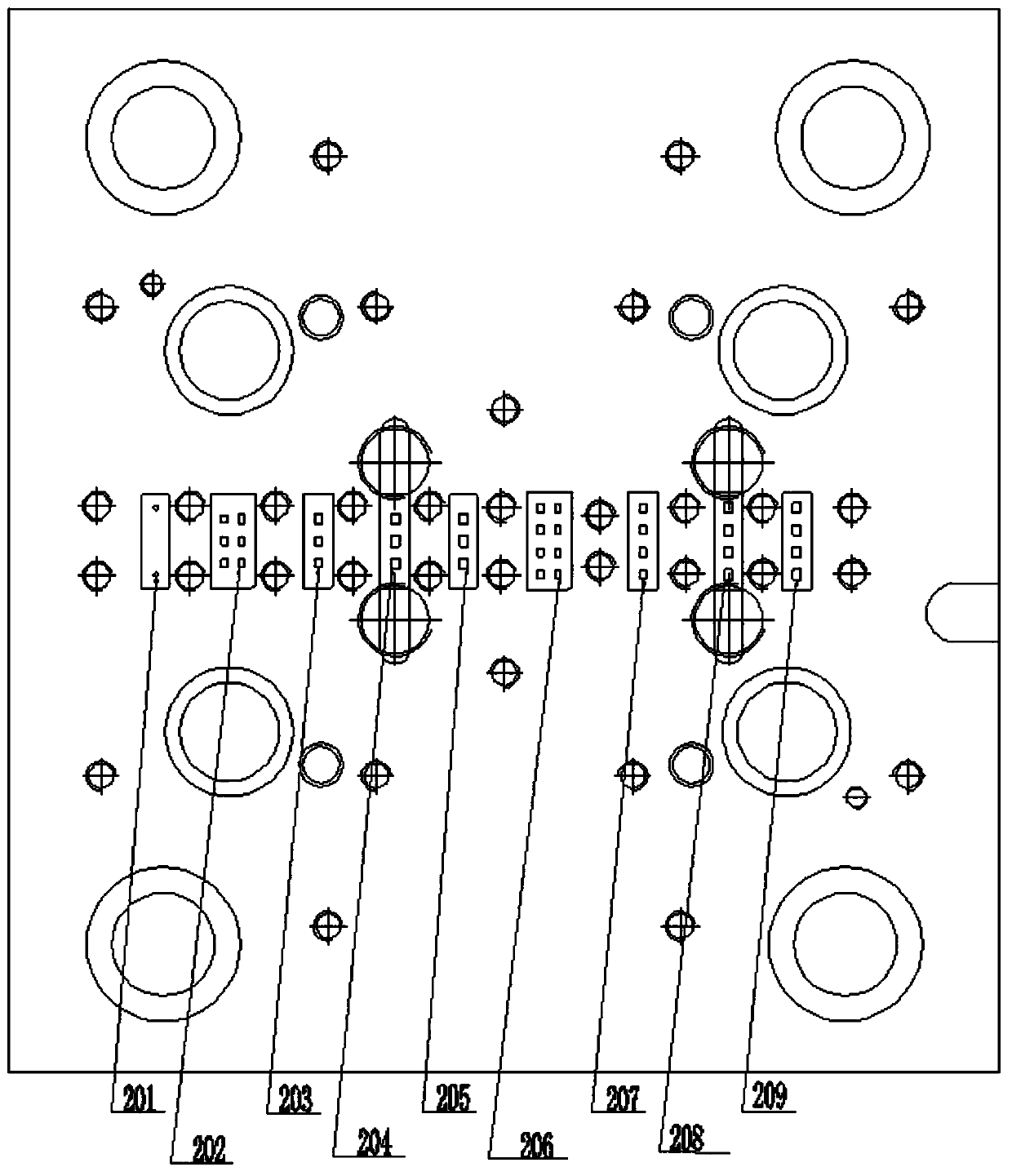

[0030] Such as Figure 1-3 As shown, a 3225 Kovar ring manufacturing mold includes a stepping mold. The stepping mold includes an upper mold base 1 and a lower template 2. The upper mold base 1 is sequentially provided with a positioning punch 101, a A three-punch assembly and a four-punch assembly; a three-punch assembly includes 3 rows and a three-punch insert set, and a four-punch assembly includes 4 rows and a four-punch insert set of parts; the lower template 2 is sequentially provided with a positioning die 201, a three-out die assembly and a four-out die assembly along the stepping direction of the stepping mold, and the three-out die assembly includes 3 rows and a three-out die assembly. Die insert set; one-out four-die set includes 4 rows, one-out four-die insert set; one-out three-punch insert set and one-out four-punch insert set are set at intervals, and one-out three-die insert set The insert group is arranged at intervals with the one-out four-die insert group. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com