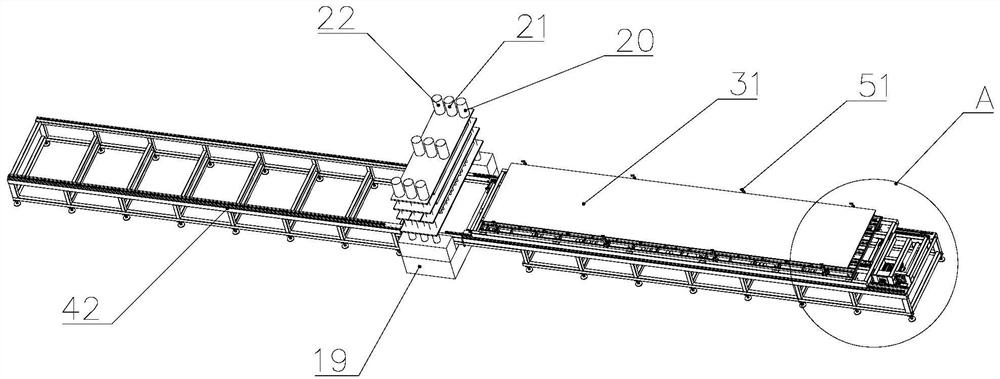

Truss 3D floor plate perforating machine

A punching machine and floor slab technology, applied in boring/drilling, drilling/drilling equipment, stone processing equipment, etc., can solve the problem of high assembly cost of steel truss floor slabs, broken drilling bits, and high damage rate. problems, to achieve the effect of improving service life, reducing breakage rate and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

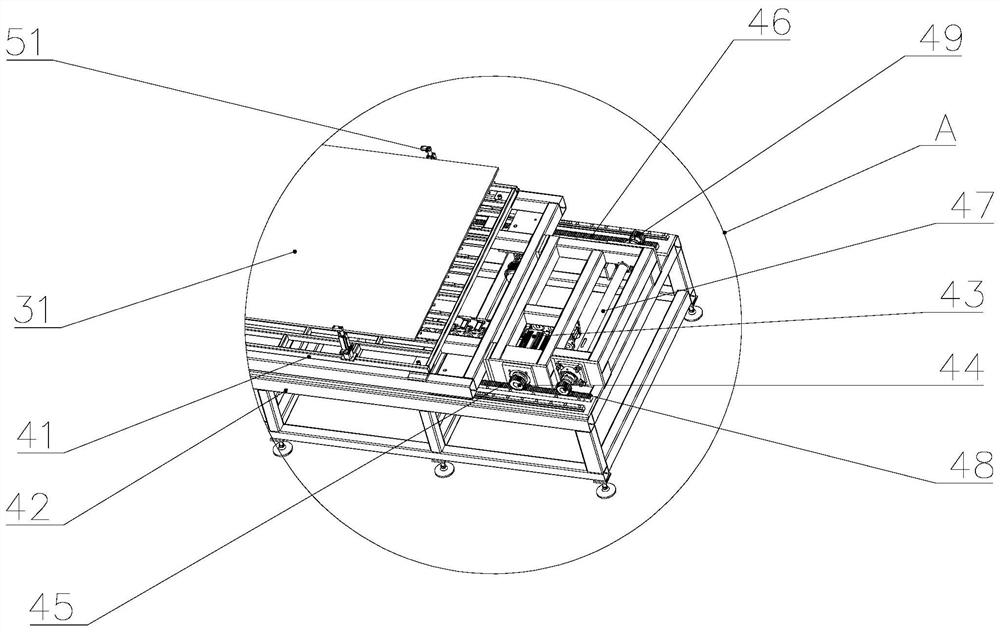

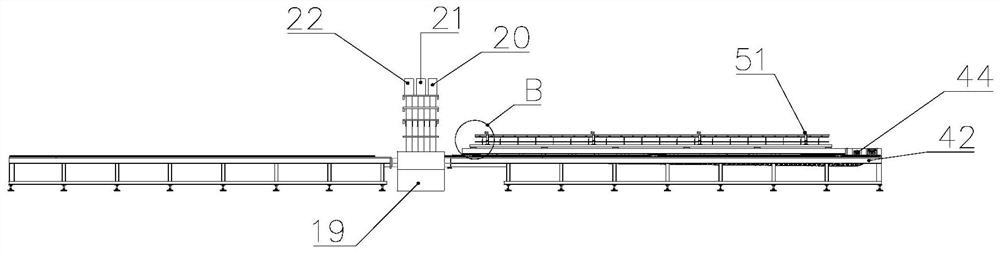

[0062] As an embodiment, the punching machine also includes a fourth drive mechanism, the fourth drive mechanism includes a power unit 43 and a main gear 44 connected to the delivery platform 41, and the first rack 45 and the first rack 45 are respectively arranged on both sides of the support beam 42. The second rack 46, the main gear 44 is meshed with the first rack 45 and / or the second rack 46; the conveying mechanism also includes a support shaft 47, and the two ends of the support shaft 47 are respectively sleeved with a first driven gear 48 and the second driven gear 49 , the first driven gear 48 is meshed with the first rack 45 , and the second driven gear 49 is meshed with the second rack 46 . By arranging the power device 43 to be connected with the conveying table 41, the main gear 44 directly drives the conveying table 41 to perform linear motion, and simultaneously the power device 43 is driven by the conveying table 41 to perform linear motion synchronously with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com