Angle steel eyelet work product line

A production line and angle steel technology, applied in the direction of piercing tools, metal processing equipment, feeding devices, etc., can solve the problems of inability to realize automatic production, difficult processing, error-prone, etc., and achieve high production efficiency of the whole machine, stable movement, and improved The effect of punching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

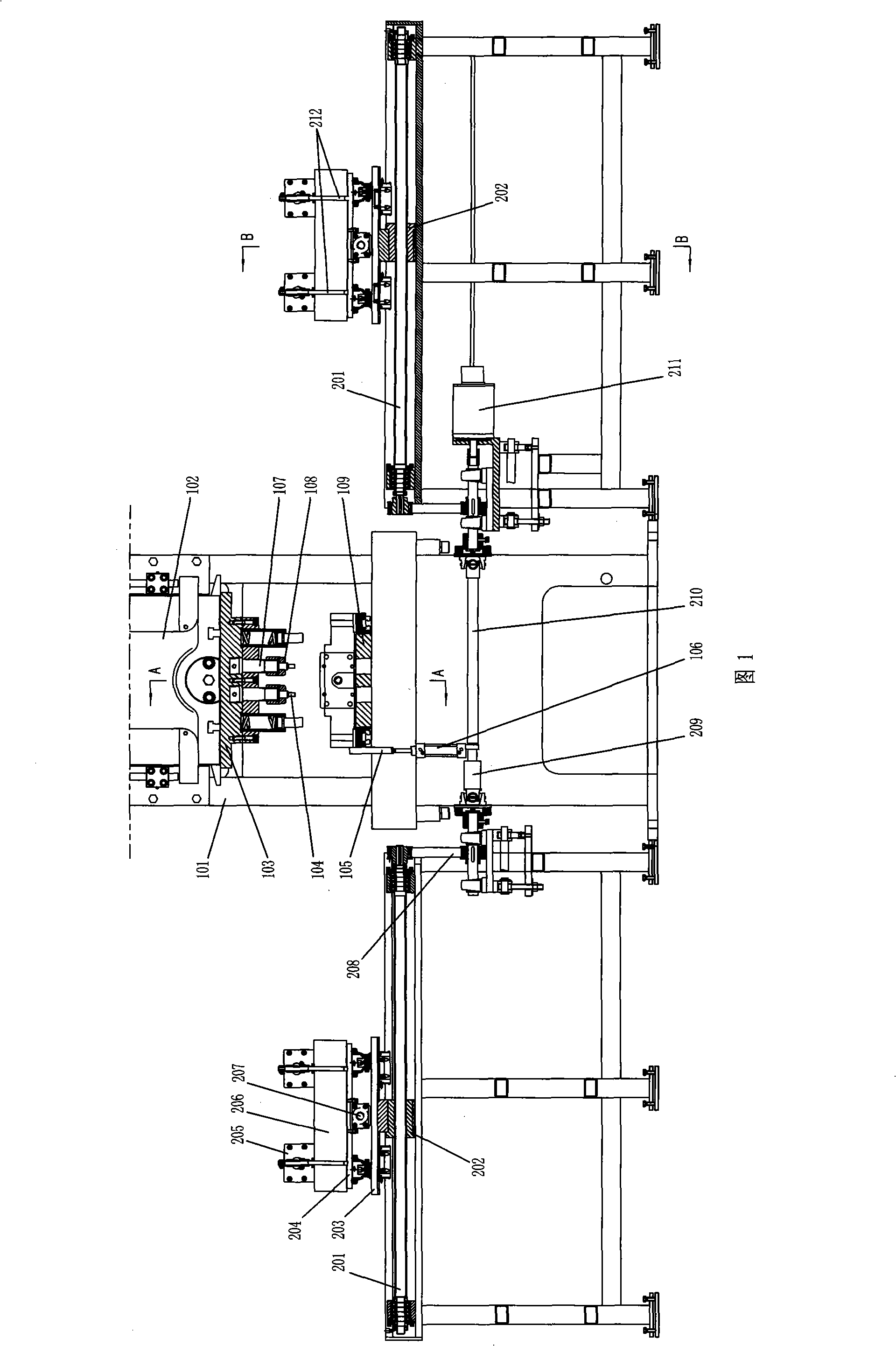

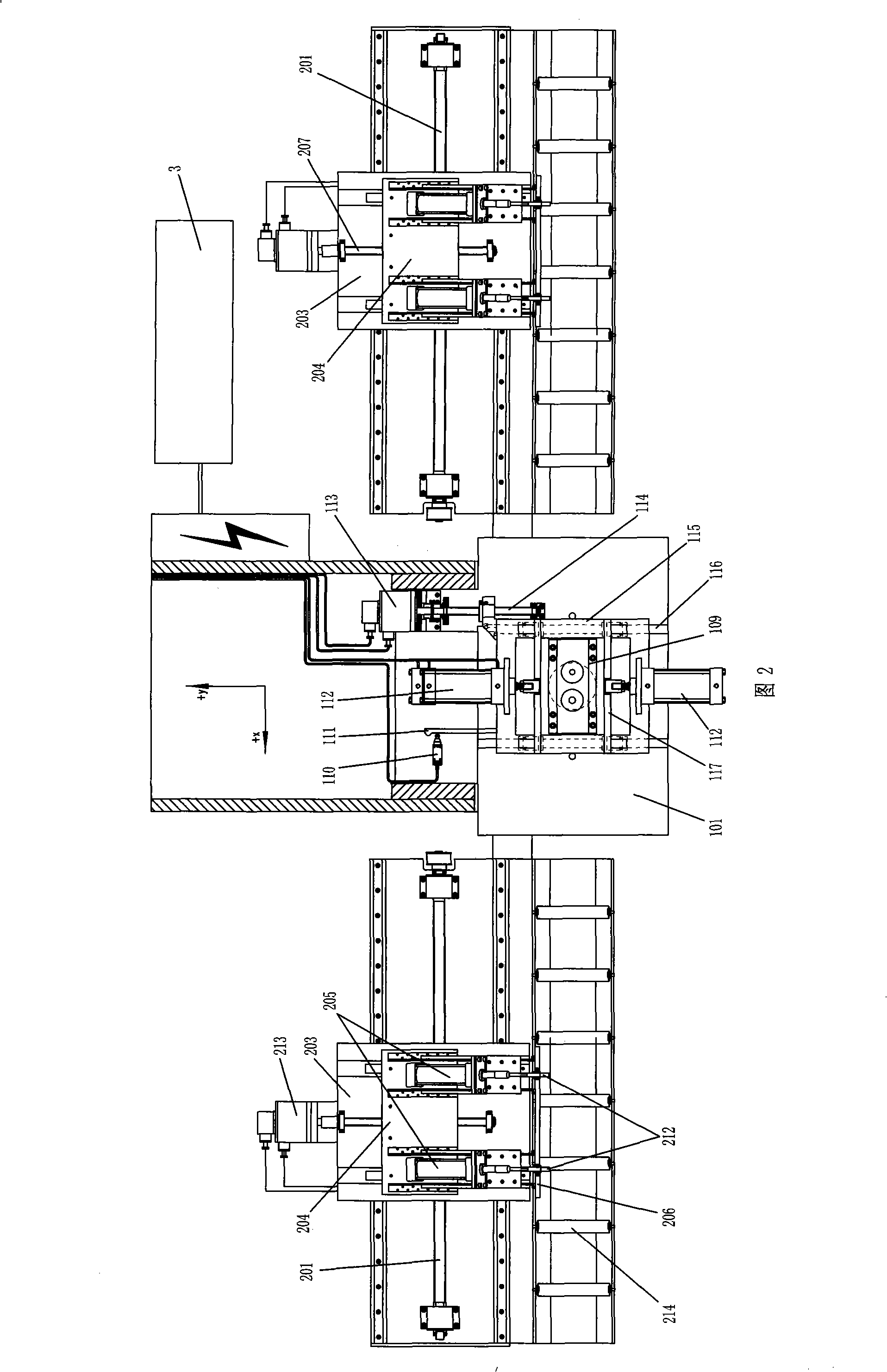

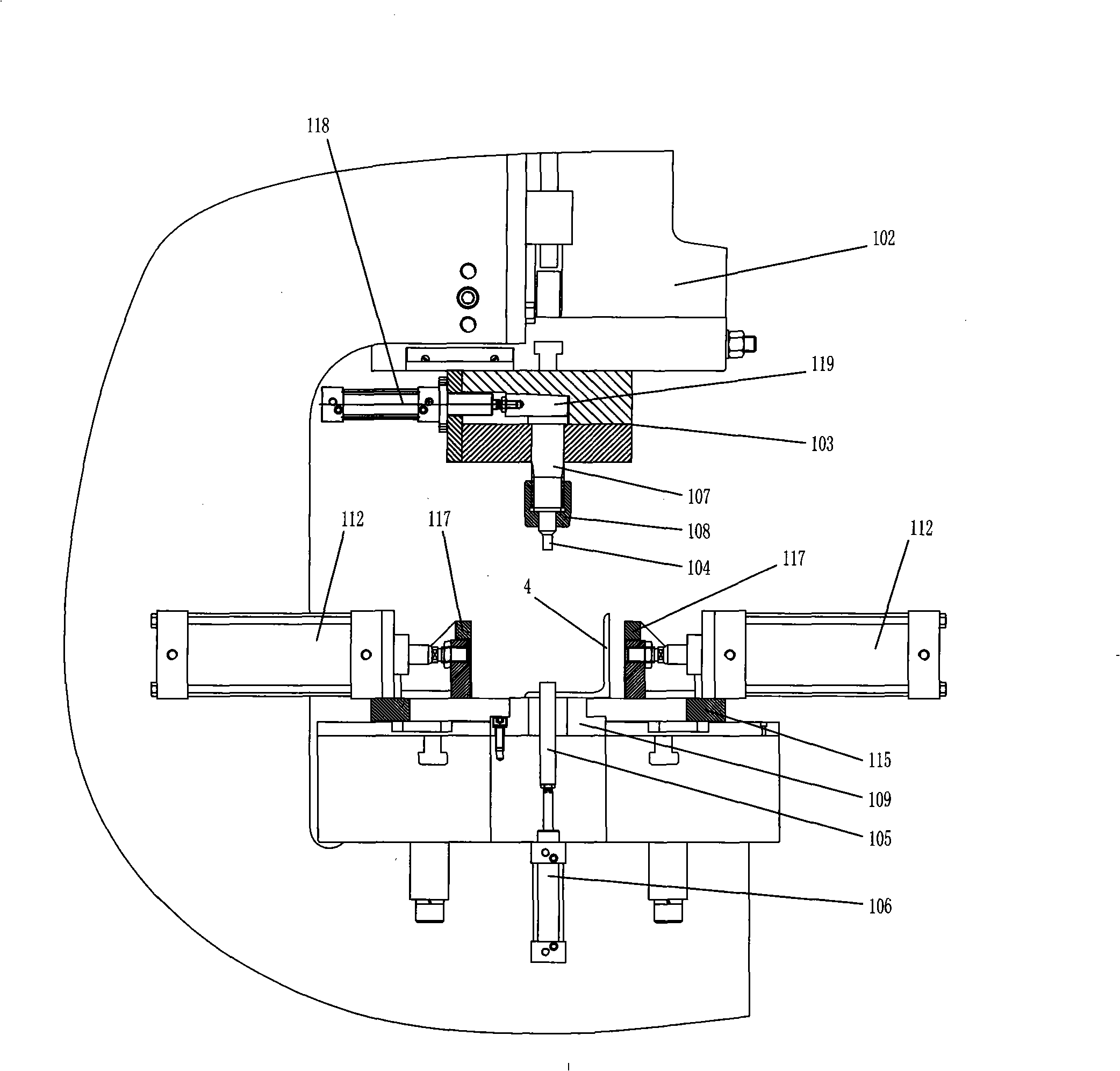

[0021] A kind of angle steel punching production line as shown in Fig. 1, Fig. 2, comprises press 101, upper die 103 is set on the slide block 102 of press 101, and lower die 109 is set on the operation table of press 101, described press Clamping and feeding devices for the angle steel workpiece 4 are arranged on both sides of the workbench of 101. The clamping and feeding devices include a workbench, and the workbench is provided with a conveying roller 214 for horizontally conveying the angle steel. One side of the conveying roller 214 There is a transverse feed carriage 203, which is horizontally slidably connected to the workbench. The plate 203 is fixedly connected to the screw cover 202, and the transverse screw 201 is connected to the transverse feed motor 211 on the workbench; the transverse feed carriage 203 is longitudinally slidably connected with a longitudinal feed carriage 204 , the turret on the horizontal feed carriage 203 is provided with a longitudinal screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com