Load-deflection resistant loading system for free hydraulic forging press

A loading system and hydraulic press technology, applied in the field of forging hydraulic presses, can solve problems such as poor anti-eccentric forging ability of the loading system, failure of the main working cylinder seal, copper sleeve and seal wear, etc., to reduce maintenance expenses, improve guiding accuracy and movement Accuracy, the effect of extending the life of the seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

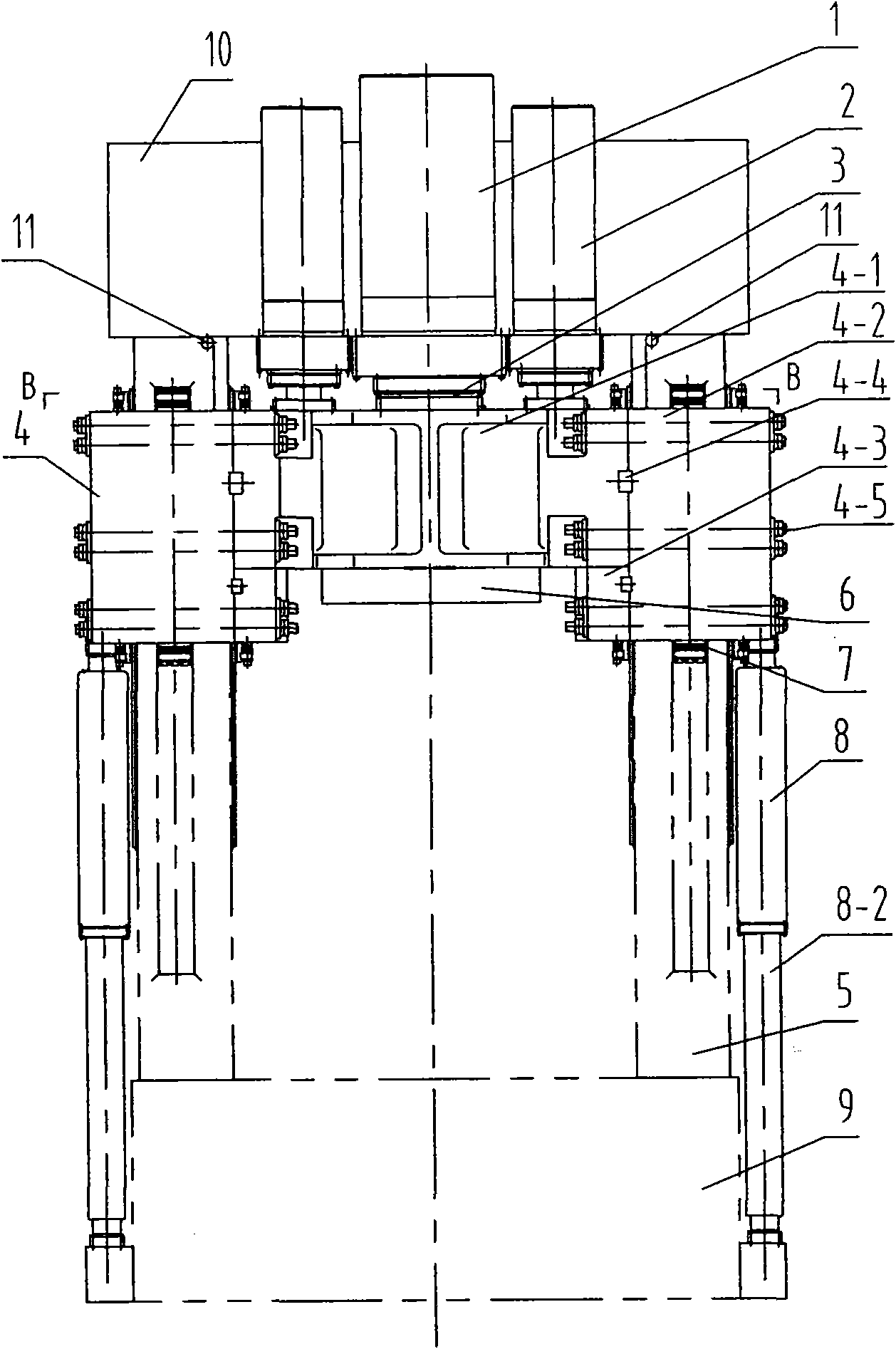

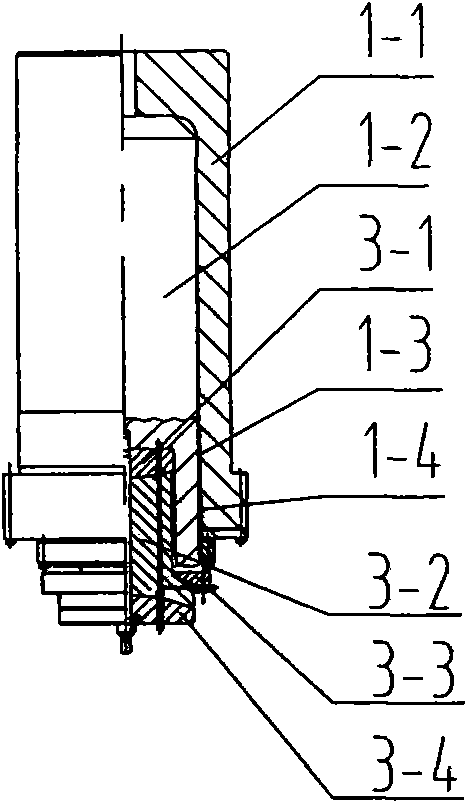

[0025] like figure 1 As shown, a free forging hydraulic press anti-eccentric load loading system, the main working cylinder is composed of a middle cylinder 1 and two side cylinders 2, which are fixed side by side on the center line of the upper beam 10 with studs. The forging force generated by each working cylinder is transmitted to the movable beam 4 through the double concave ball hinged short cylinder rocker shaft device 3 in the main plunger.

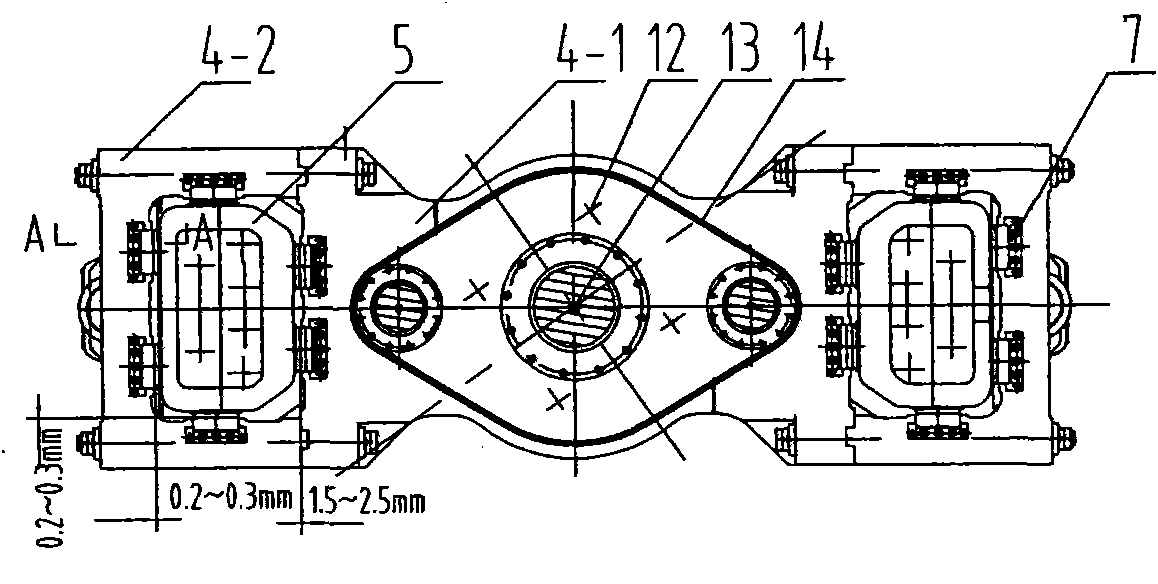

[0026] The movable crossbeam is made up of five pieces of middle crossbeam 4-1, two guide frames 4-2 and two guide beams 4-3, and it is connected and fastened by several groups of keys 4-4 and fastening pull rods 4-5 to form a The combined movable beam 4 of the full prestressed rectangular column 5 is slidably fitted. An upper backing plate 6 is fixed under the movable beam, and at least 4 wedge-shaped plane guides with adjustable gaps perpendicular to each other are installed on the upper and lower parts of each column hole corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com