Steel-concrete interface shear force connecting piece fatigue performance test apparatus and application method thereof

A fatigue performance testing, concrete technology, applied in the direction of using repetitive force / pulsating force to test the strength of materials, can solve the problems of size limitation, uneven force, large load, etc., to prevent eccentricity problem, ensure accuracy, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

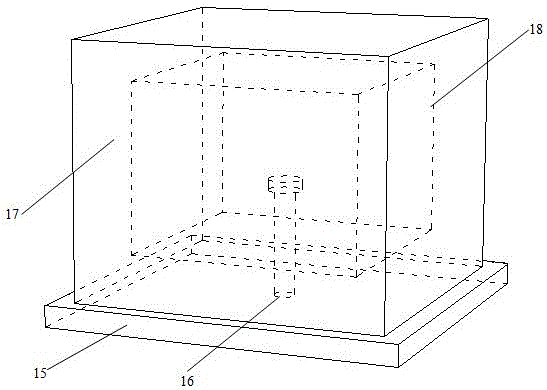

[0023] Such as figure 1 As shown, the test piece for carrying out the shear bearing capacity test of the steel-concrete interface shear connector according to the present invention includes a steel plate 15, a concrete block 17, a stirrup 18 and a shear connector 16, and the shear connector Part 16 is one, the concrete block 17 is cuboid and its cross section is square, and the stirrup 18 is formed by the binding of steel bar 19, and a cross section that encloses is a square cuboid frame; The stirrup 18 is poured in the concrete block 17 , the geometric center of the stirrup 18 coincides with the geometric center of the concrete block 17, and two opposite sides of the cross section of the stirrup 18 are parallel to two opposite sides of the cross section of the concrete block 17; the concrete block 17 is poured on the steel plate 15 , the rod end of the shear connector 16 is welded on the steel plate 15 , and the shear connector 16 is perpendicular to the steel plate 15 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com