Fatigue testing device and fatigue testing method for traction connecting rod system of single-rail cart

A traction link and fatigue test technology, applied in the field of experimental equipment and test technical solutions, can solve the problems of no technical solutions, devices and papers, no retrieval of technical solutions and devices for the traction link system of a monorail car, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

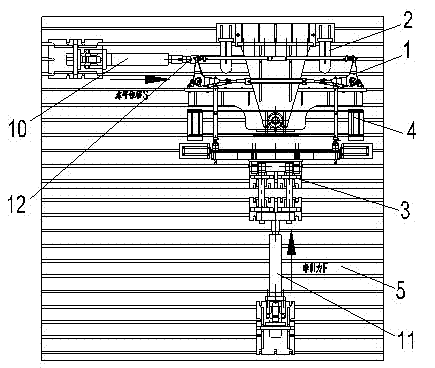

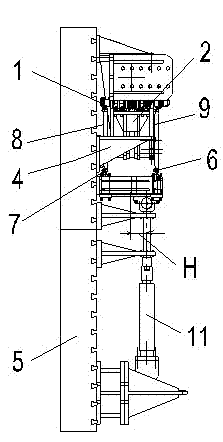

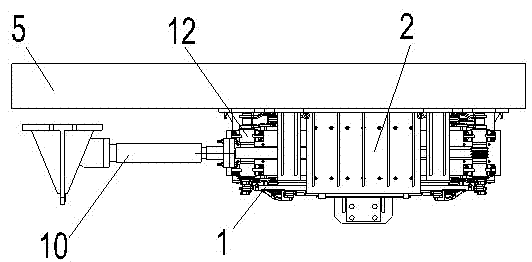

[0030] The accompanying drawings show an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

[0031] A monorail vehicle traction linkage system fatigue test method, the test method is:

[0032]Place the traction link system in a simulated car body and bogie system, install it horizontally on the test platform as a whole, and carry out combined loading on it from the vertical and lateral (horizontal) directions respectively through the loading cylinder and the test fixture , in which the upper ball joints of the four traction rods of the traction linkage system are fixed on the bearing platform of the simulated car body device by bolts, and form a double torsion bar mechanism with a four-link internal force balance. -190mm) to install a hinge device, the hinge device passes through 4 guide seats in parallel and connects with the vertical loading cylinder through the loading beam, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com