New-type binding machine

A binding machine and a new type of technology, applied in binding, metal processing and other directions, can solve the problems of unreasonable, increased cost, complex transmission structure, etc., and achieve the effect of good linkage effect, stable connection and reasonable transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

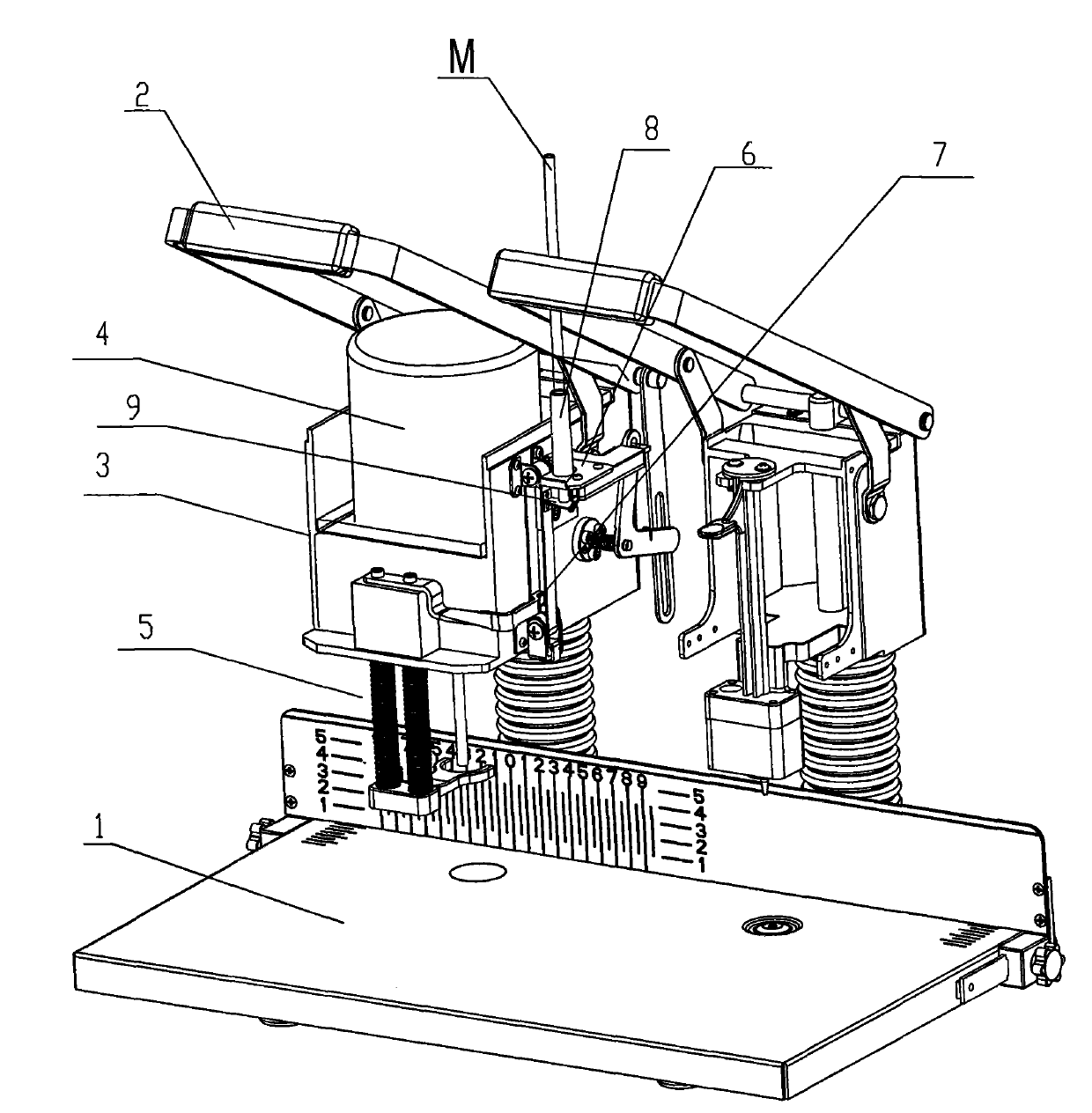

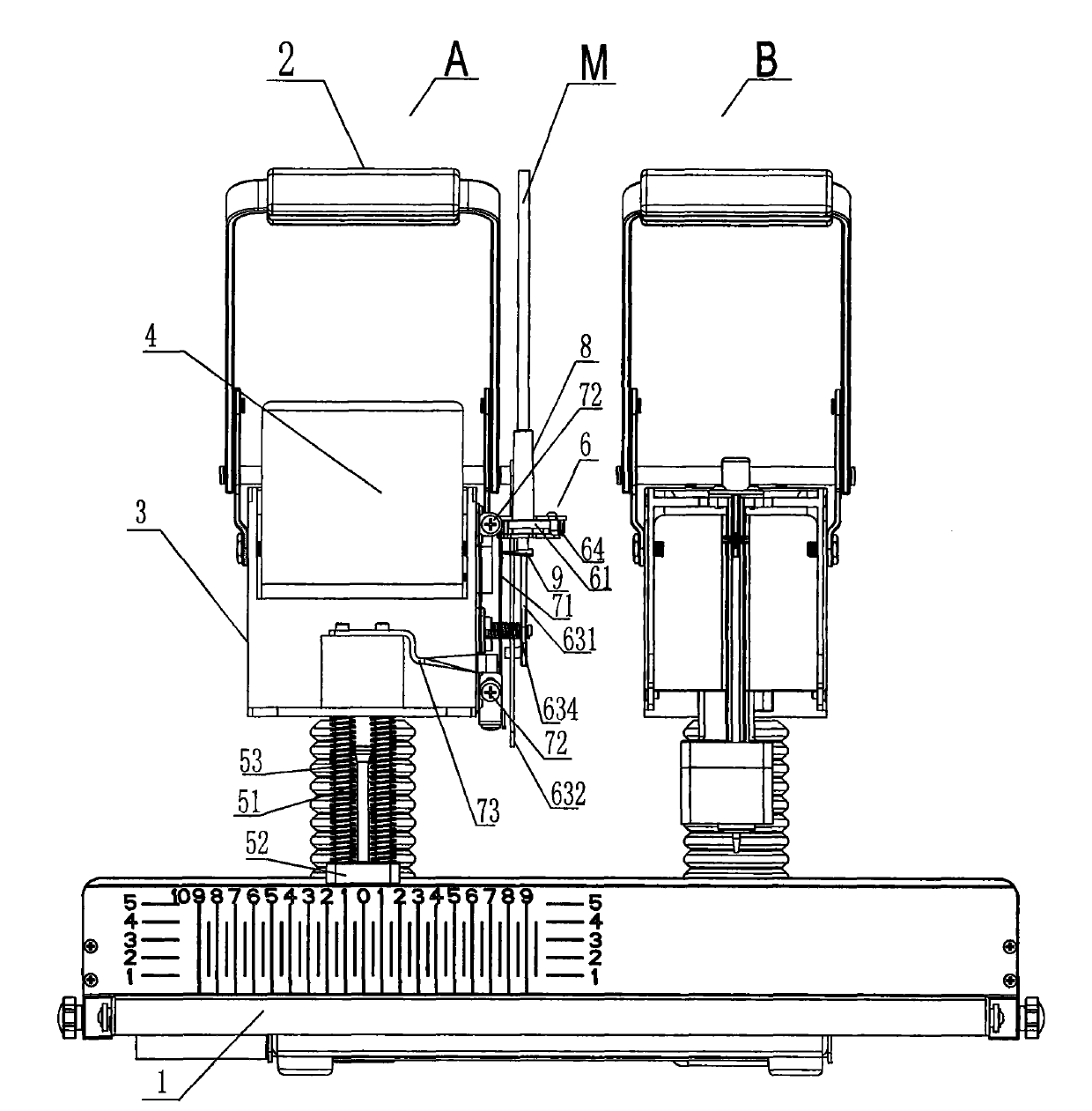

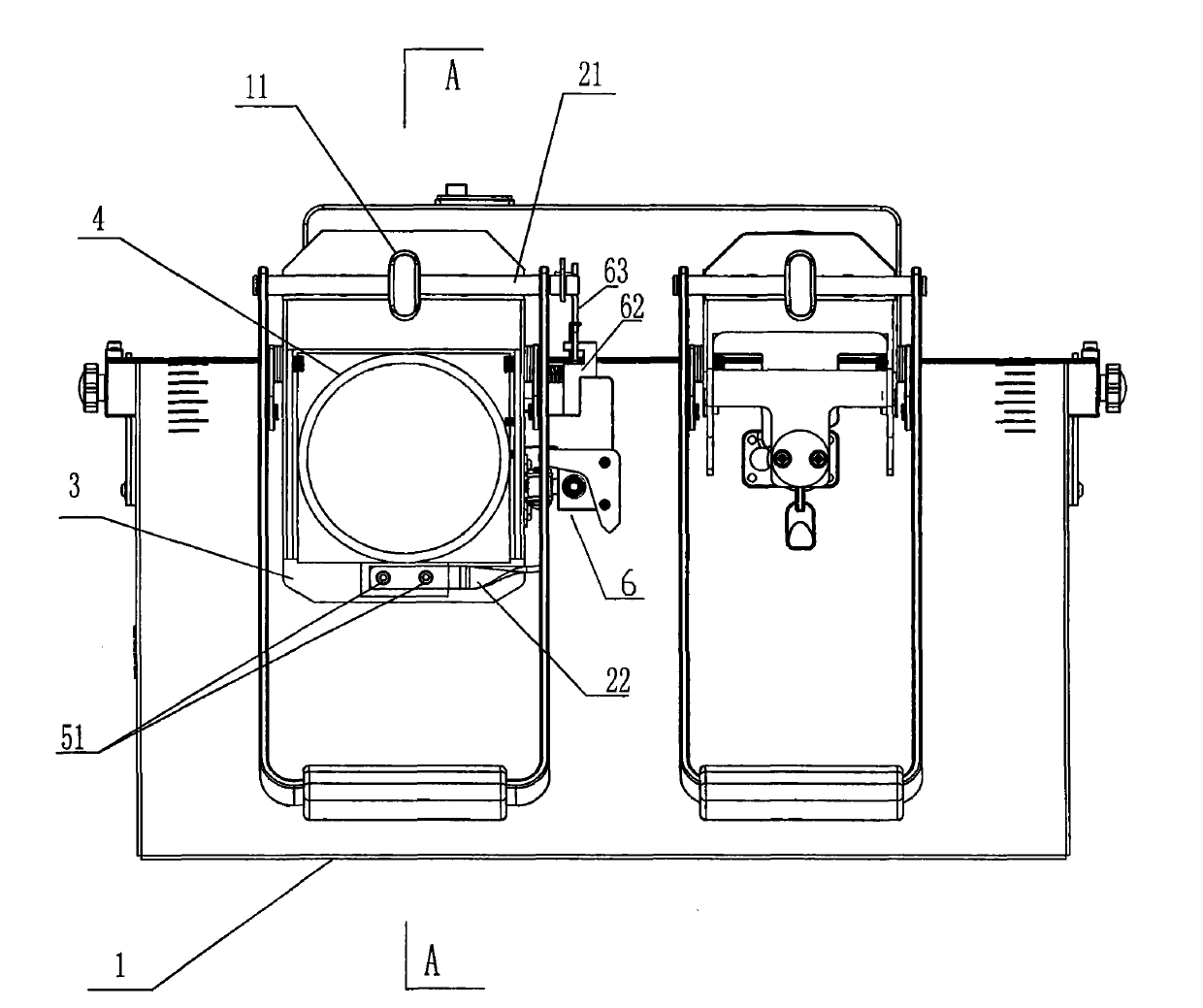

[0034] Such as Figure 1 to Figure 12 As shown, a novel binding machine of the present invention includes a drilling motor 4, a paper pressing device 5, a pipe cutting device 6 and a conduit tube 8 arranged on a liftable motor base 3, and the paper pressing device 5 is positioned on the motor base 3 It can be reset and lifted, and also includes the base 1, the manual pressing rod 2 and the main shaft 11 on the base 1. The motor base 3 is arranged on the main shaft 11, which can be lifted and reset automatically. , between the outer part and the motor seat 3, there is a hinged link piece 22 for interlocking, and the free outer end is a handle; the pipe cutting device 6 is vertically opposite to the catheter tube 8; Guiding and lifting guide device 7, the guide device 7 is provided with a measuring tube supporting plate 9 opposite to the nozzle of the catheter tube 8;

[0035] Such as Figure 9 , Figure 10 As shown, the guiding device 7 includes a synchronous belt 71 and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com