A riveting structure and automatic binding machine

A technology of riveting and pressing devices, applied in the direction of binding, etc., can solve problems such as inability to achieve complete locking, slippage, and insufficient tightness of binding objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

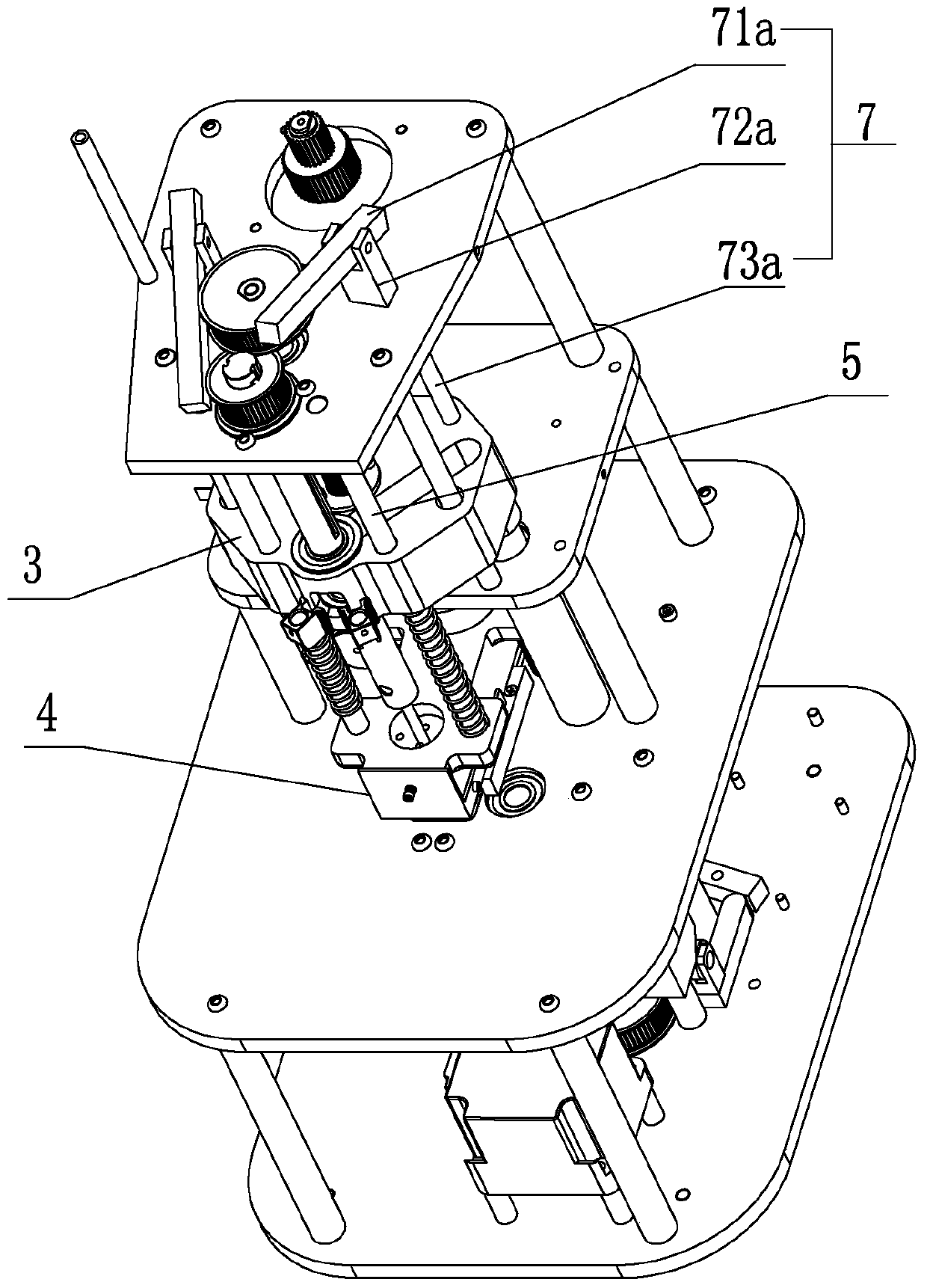

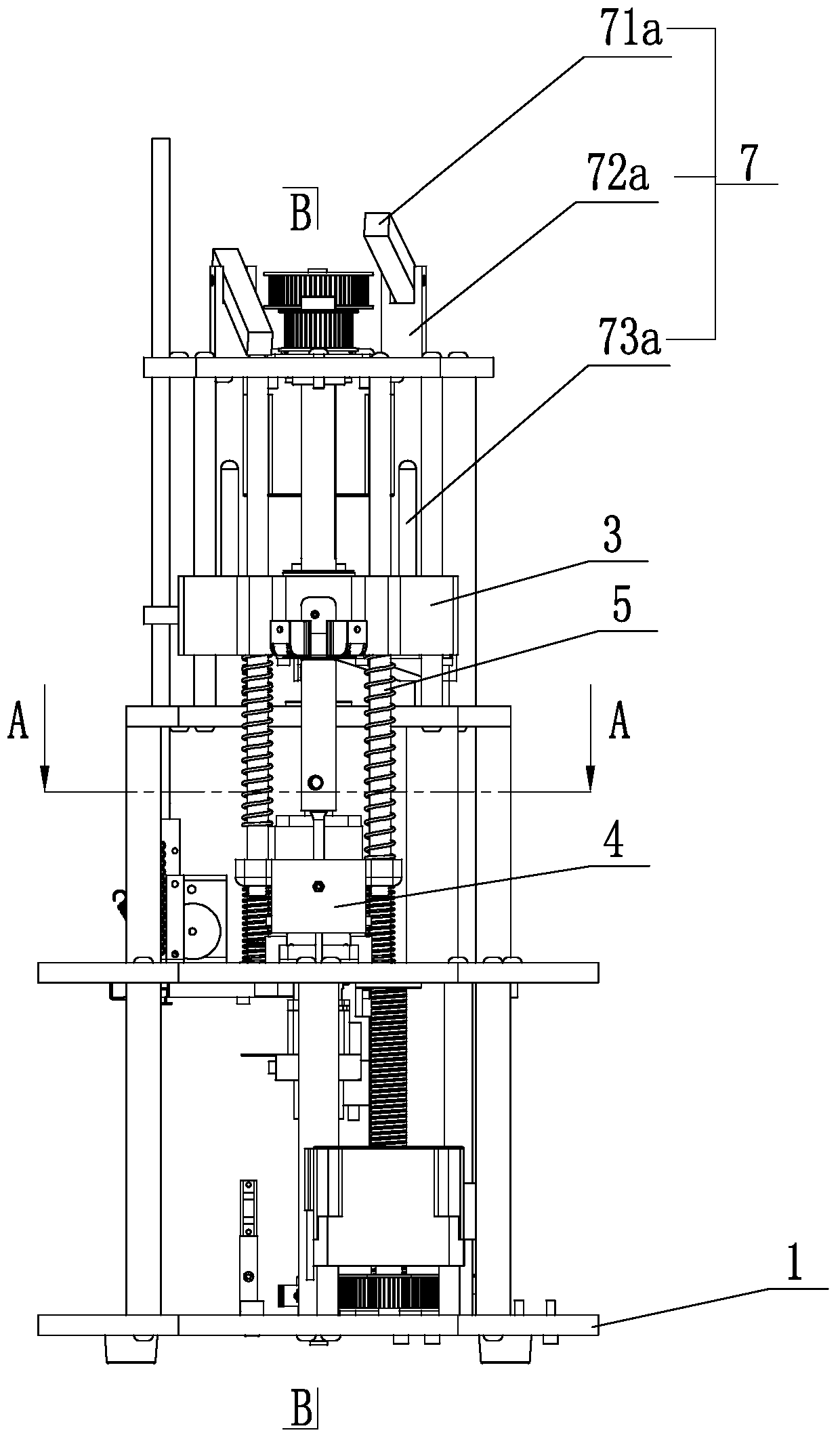

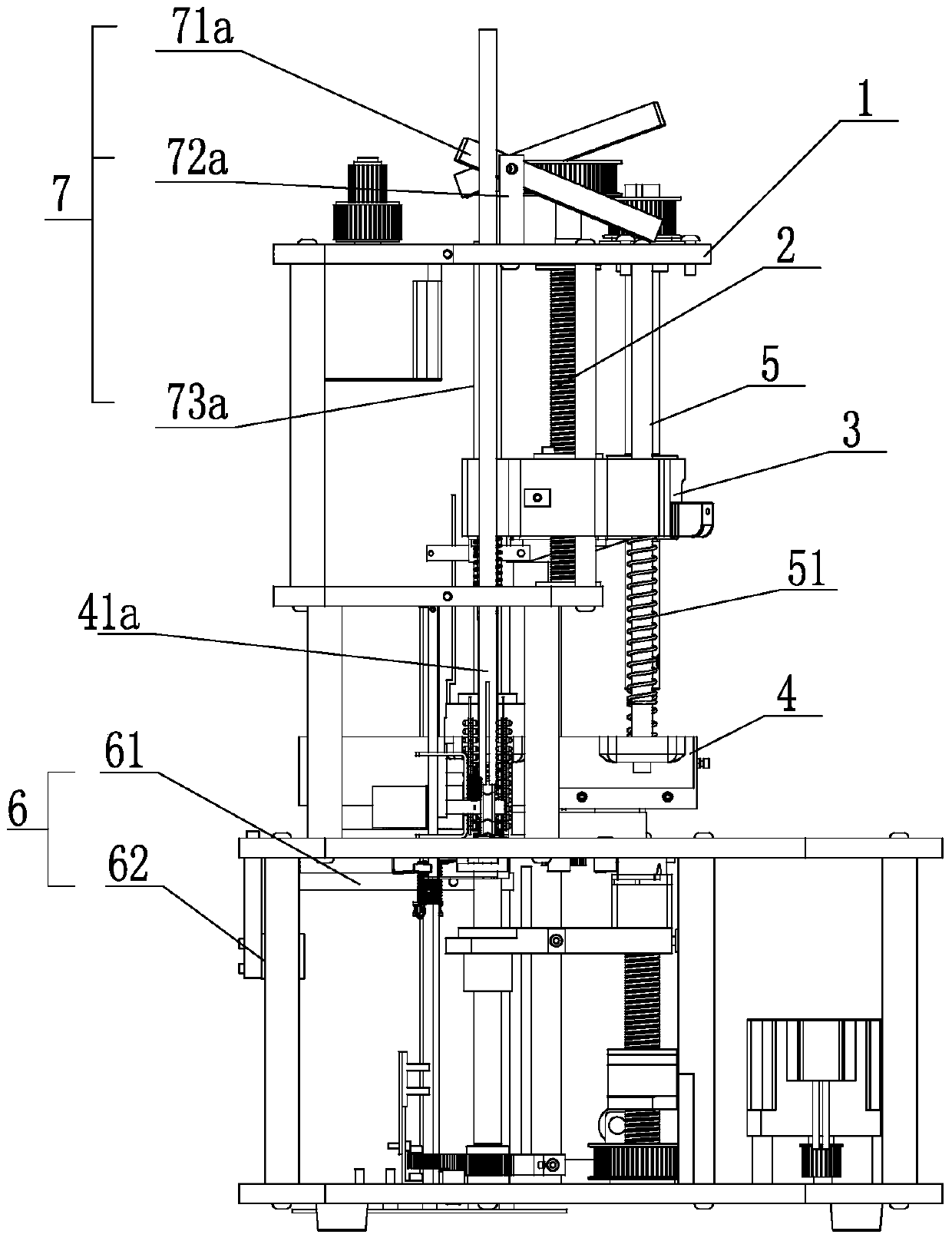

[0052] Such as Figure 1 to Figure 28 As shown, a riveting structure includes a lifting seat 3, a riveting head device 4, and a pressing device 7 in a frame 1. The lifting seat 3 is connected to the riveting head device 4 and can move downward, and the pressing device 7 utilizes the lifting seat 3. Lifting force is converted into downward acting force to press riveting head device 4.

[0053] The frame 1 is provided with a vertical guide column 2, and a lifting seat 3 can be lifted and positioned on the vertical guide column 2.

[0054] The rivet head device 4 includes a paper pressing block 41 for positioning the rivet head.

[0055] The frame 1 is provided with a lifting guide rod 5 , and the lower end of the lifting guide rod 5 is connected with a paper pressing block 41 .

[0056] Frame 1 is provided with follow-up brake device 6, and follow-up brake device 6 is connected lifting seat 3 riveting head device 4 follow-up brakes.

[0057] A riveting structure of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com