A kind of drilling device and automatic binding machine

A drilling device and frame technology, applied in the direction of binding, etc., can solve the problems of inaccurate transmission, increased motor operating load, noise and motor loss, etc., and achieve the effect of simple and reasonable linkage structure and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

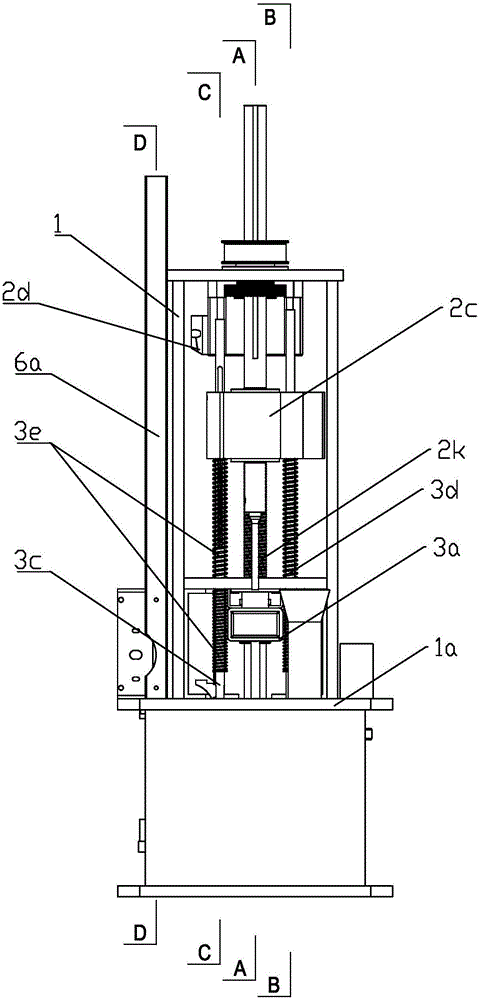

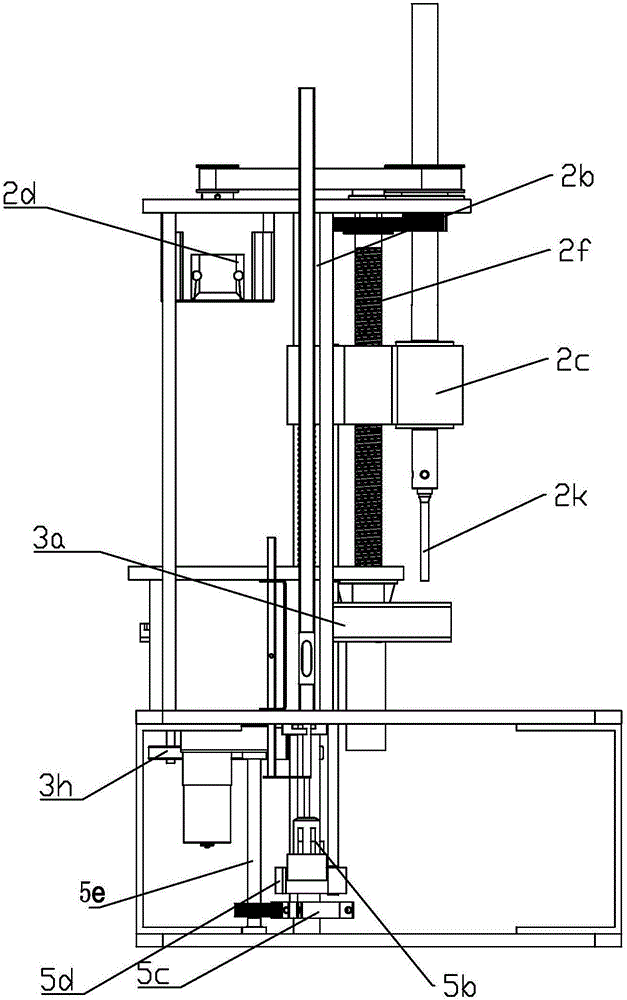

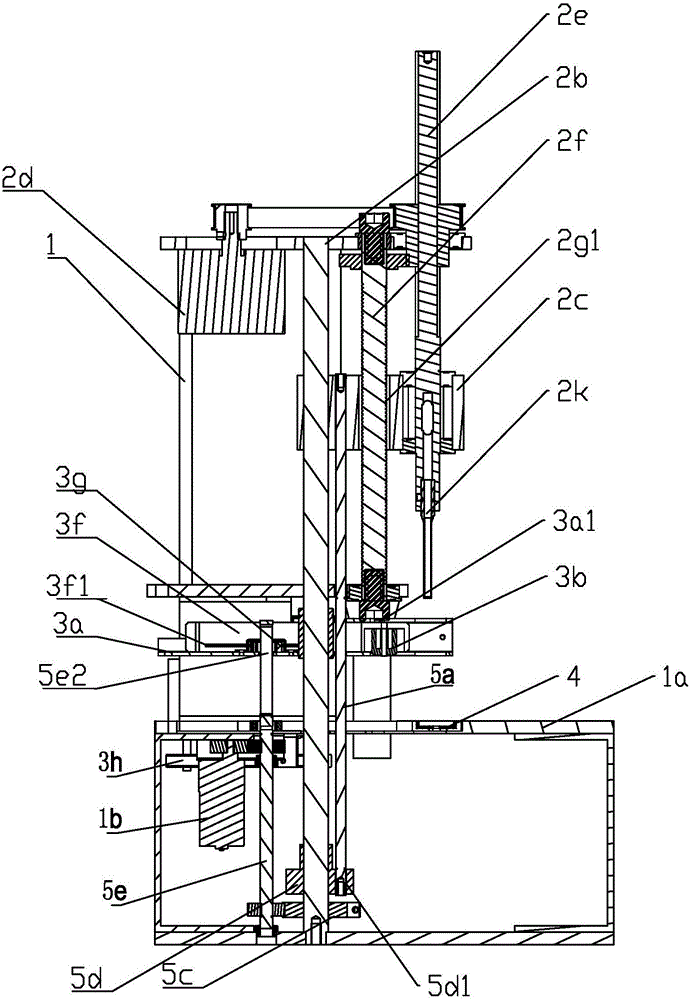

[0072] Such as Figure 28 ~ Figure 35 Shown, a kind of drilling device comprises frame 1, lifting base 2c, first motor 2d, drilling rotating shaft 2e and drill 2k, is also provided with rotatable vertical screw rod 2f in the frame, and lifting base 2c is set There is a screw hole 2g1, the lifting base 2c can be lifted and screwed on the vertical screw 2f through the screw hole 2g1, the drilling shaft 2e is rotatably connected to the lifting base 2c, and the lower end is connected to the drill bit 2k, and the first motor 2d is fixed on the frame 1 The upper and output shafts are connected to the drilling rotating shaft 2e and the vertical screw rod 2f to rotate simultaneously.

[0073] The frame 1 is provided with a vertical guide post 2b, and the lifting seat 2c is limited to move up and down between the vertical guide post 2b and the vertical screw rod 2f.

[0074] The upper part of the drilling shaft 2e is provided with an axial sliding groove 2e2, the sliding groove 2e2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com