Printing ink-jet head manufacturing apparatus

A technology of inkjet head and manufacturing device, which is applied in the field of parts manufacturing, can solve the problems of high processing cost and complicated manufacturing steps, and achieve the effects of simple structure, convenient operation and use, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

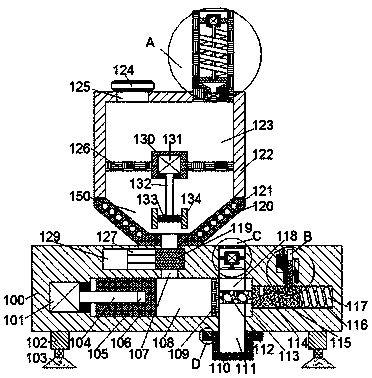

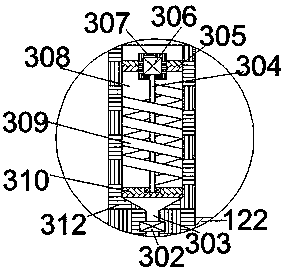

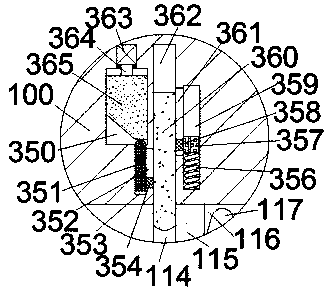

[0018] Such as Figure 1-5As shown, a printing inkjet head manufacturing device of the present invention includes a device main body 100 and a heating device fixedly installed above the device main body 100, and the heating device includes a heating chamber fixedly installed above the device main body 100 The main body 120, the heating chamber main body 120 is provided with a heating chamber 150, and the lower end wall of the heating chamber 150 is provided with an upwardly extending slope, the heating resistance wire 121 is fixedly installed in the slope, and the heating chamber main body 120 is fixed above A material storage cavity main body 122 is installed, and a material storage cavity 123 communicating with the heating cavity 150 is arranged in the material storage cavity main body 122, and an inlet connected to the outside world is provided on the left side of the upper end wall of the storage cavity 123. A material port 125, a seal cover 124 is slidably installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com