Automatic binding machine

A binding machine, fully automatic technology, applied in the direction of binding, etc., can solve the problems of unstable switching, complex linkage structure, unstable binding quality, etc., to achieve the effect of simple and reasonable linkage structure, reasonable linkage structure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

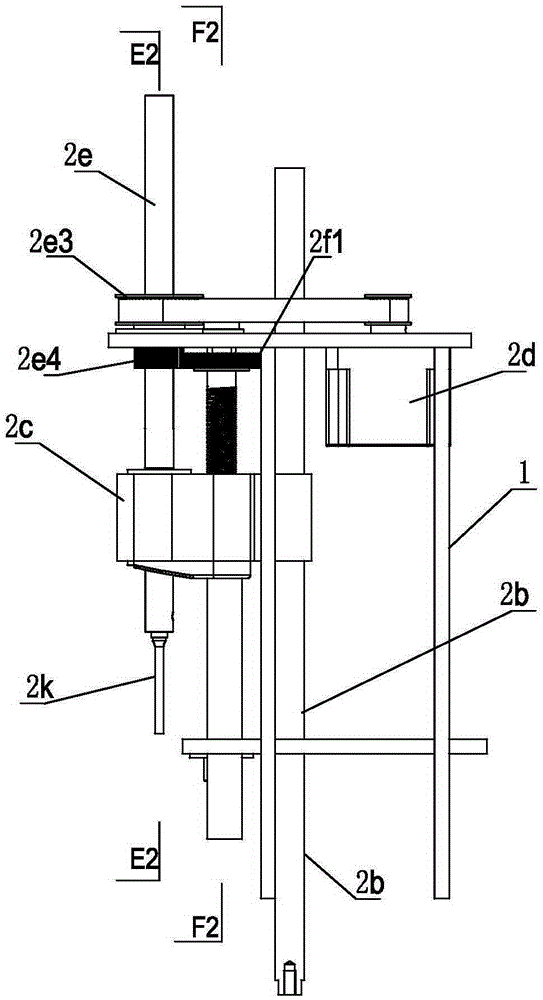

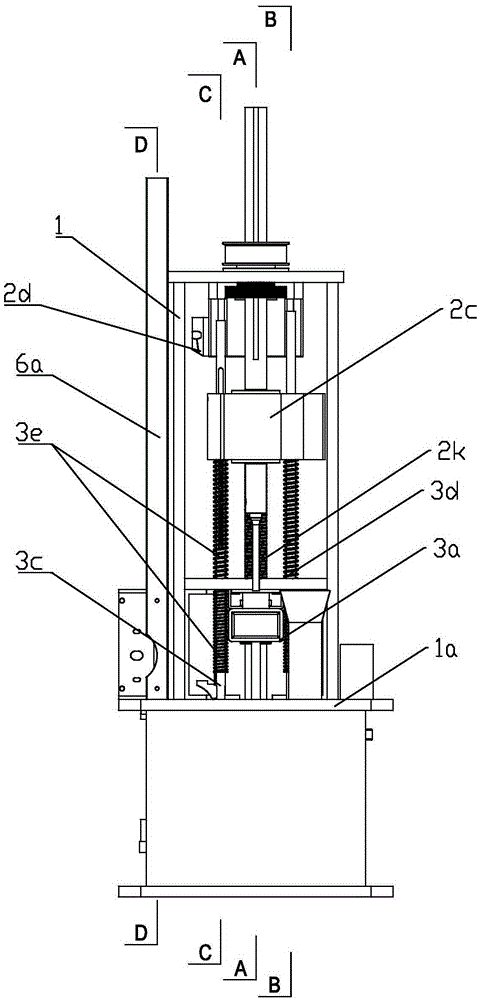

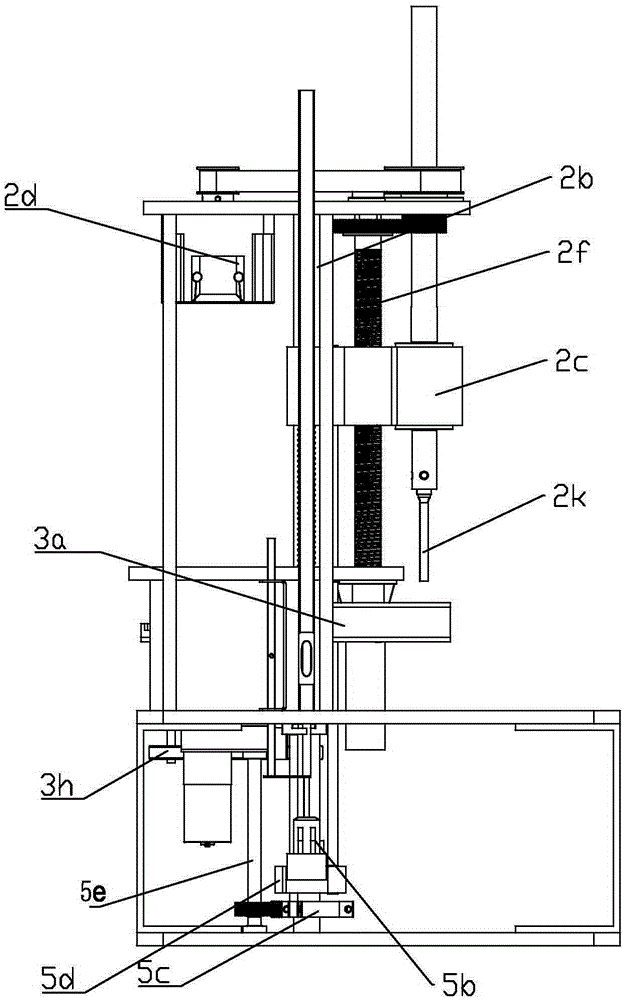

[0072] Such as Figure 1 to Figure 43 As shown, a fully automatic binding machine includes a frame 1, a second motor 1b, a drilling device 2, a lifting seat 2c, a paper pressing device 3, an upper thermal riveting head 3b, a knife shim 4 and a lower thermal riveting head 5b, The vertical guide column 2b and the horizontal work surface 1a are set in the frame 1, the lifting seat 2c can be lifted and positioned on the vertical guide column 2b, and the paper pressing device 3 can be lifted and positioned between the lifting seat 2c and the work table 1a through the spring 3e , the upper hot riveting head 3b is set in the paper pressing device 3 and can move horizontally, the knife shim 4 is set on the working table 1a and can move horizontally, and the lower hot riveting head 5b is positioned on the vertical guide column 2b on the lower side of the horizontal working table 1a It can be lifted and rotated. There is a first rotating link 5e between the upper hot riveting head 3b, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com