Laser processing equipment for full-automatic solar battery piece

A solar cell and laser processing technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of high use cost, low degree of automation and low production efficiency in the later stage, and achieve lower production costs and stable processing. Strong performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

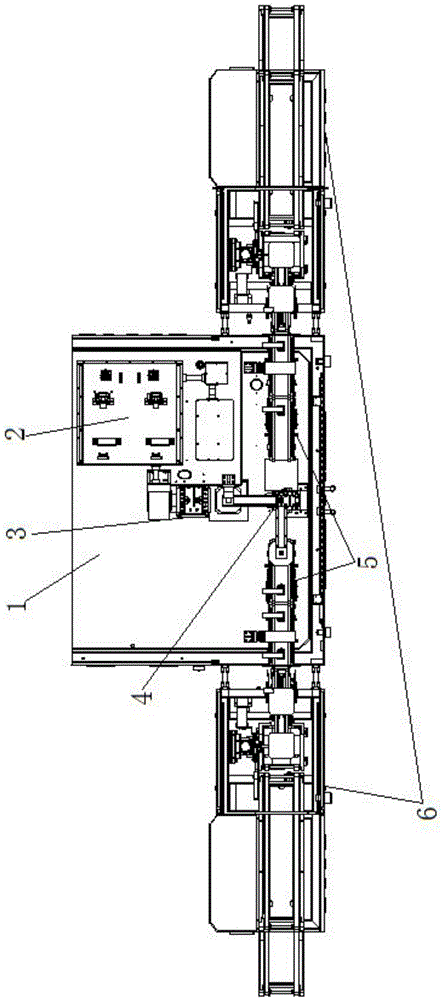

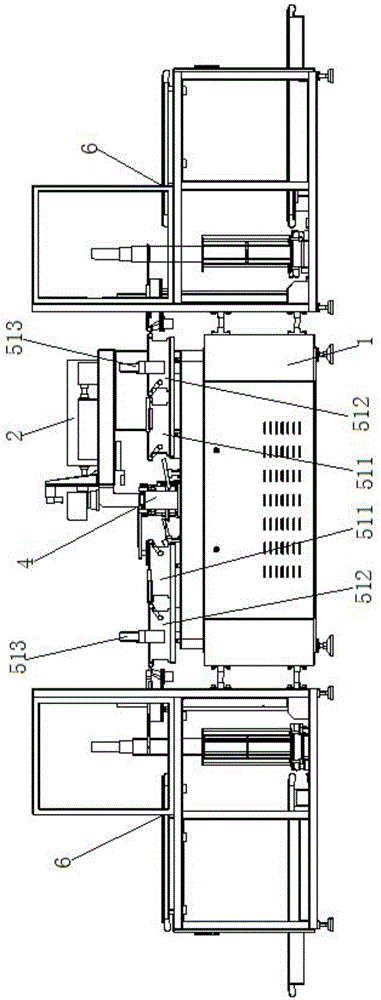

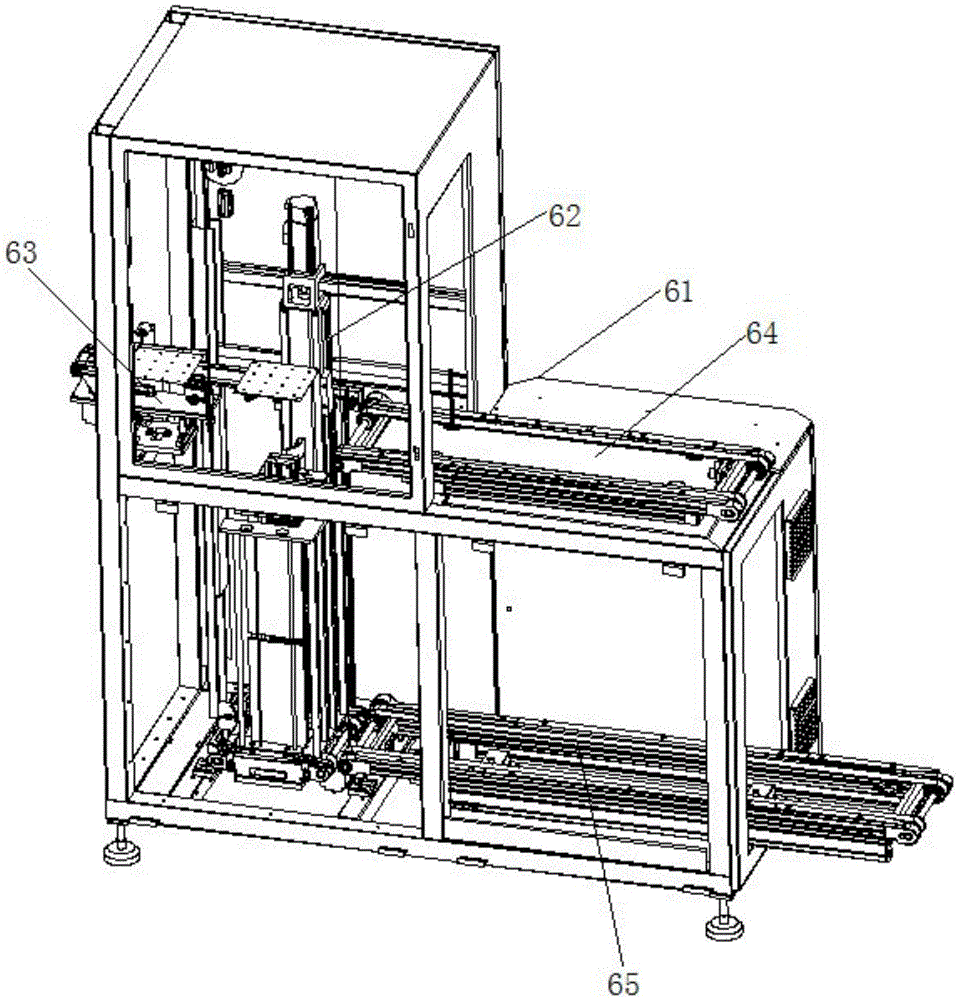

[0050] Example one: such as figure 1 with 2 As shown, the fully automatic solar cell laser processing equipment of this embodiment includes a workbench 1, a laser processing host 2, a cell processing table 3, a rotating mechanical arm assembly 4, a left and right cell buffer transfer assembly 5, and a left and right cell connection Barge assembly 6;

[0051] The laser processing host 2 and the cell processing table 3 are both installed on the workbench 1, and the cell processing table 3 is located below the laser processing head of the laser processing host 2;

[0052] The rotating mechanical arm assembly 4 is installed on the workbench 1 on the side of the cell processing table 3, and can rotate horizontally on the workbench 1;

[0053] The left and right cell buffer transfer assemblies 5 are installed on the workbench 1 on both sides of the rotating mechanical arm assembly 4. During the rotation of the rotating mechanical arm assembly 4, its free ends can be respectively rotated to...

Embodiment 2

[0067] Embodiment two: such as Figure 14 to 16 As shown, the cell processing table 3, the rotating mechanical arm assembly 4, the left and right cell buffer transfer assemblies 5, and the left and right cell connection assemblies 6 in the first embodiment form a single-line processing system, and the laser processing host 2 is provided with Two laser processing heads, and the same over-spectroscopy processing, make the two laser processing heads emit lasers independently for processing. The above-mentioned single-line processing system is provided with two, and they are installed on the workbench 1 on both sides of the laser processing host 2, so that The entire device forms a two-line processing system, and the corresponding two cell processing tables 3 are respectively installed under the two laser processing heads, that is, the entire device can independently form two processing production lines, and the two single-line processing systems are opposite Independent, when one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com