Automatic tin soldering device for multimedia interface line and working method for automatic tin soldering device

A multimedia interface and automatic welding technology, applied in auxiliary devices, welding equipment, metal processing and other directions, can solve the problems of low processing efficiency and increase equipment cost, and achieve the effect of high processing efficiency, low equipment maintenance cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

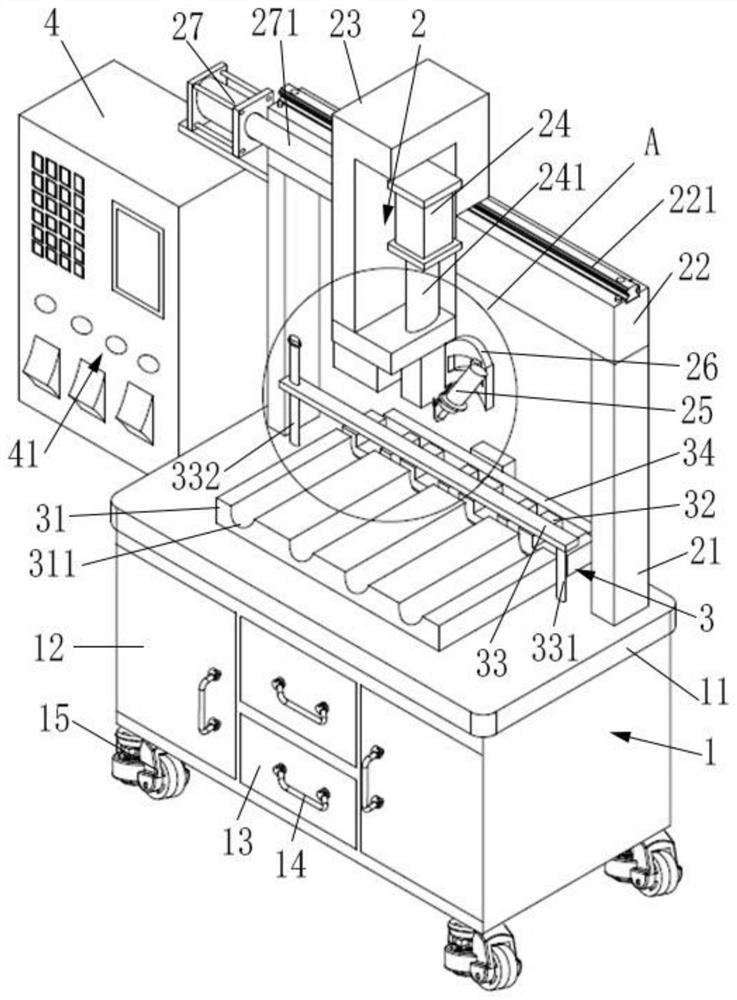

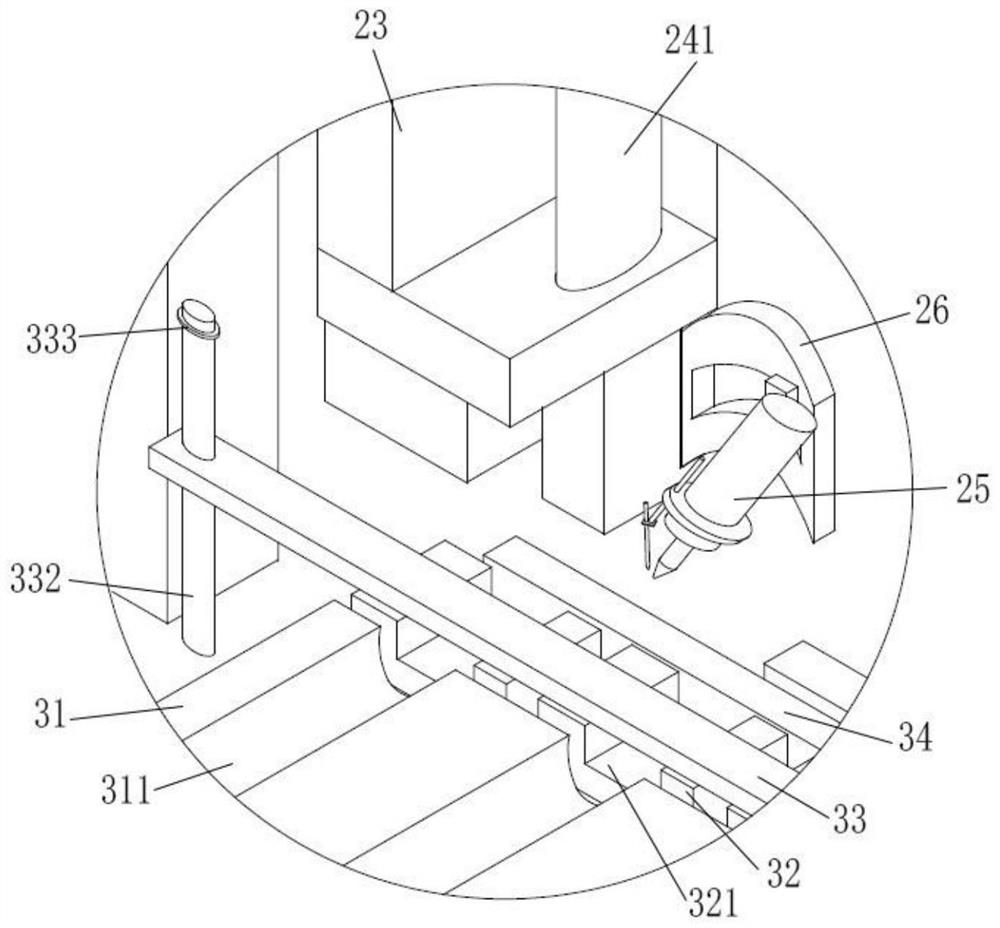

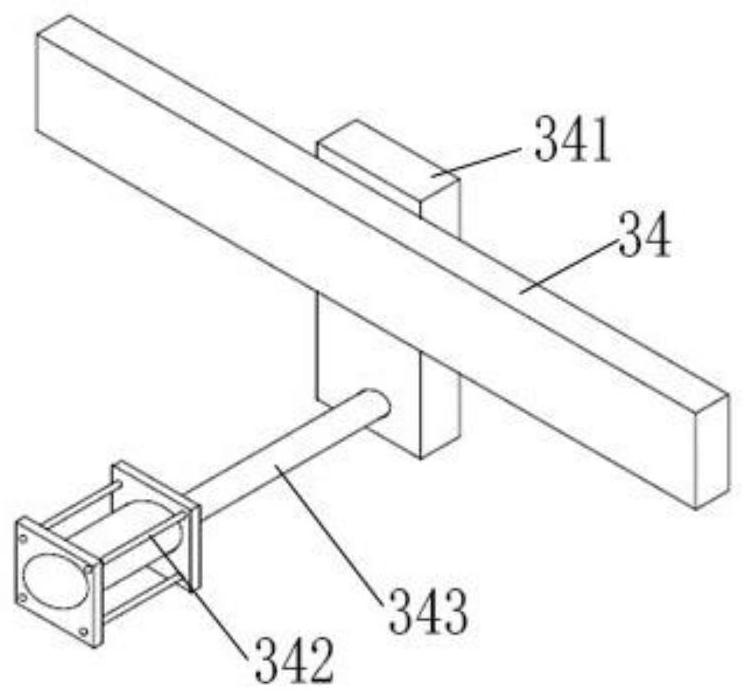

[0029] Such as Figure 1-2 As shown, an automatic soldering device for a multimedia interface line includes a frame 1, a soldering part 2 and a placement part 3, the frame 1 is provided with a workbench 11, and the soldering part 2 includes a pair of supporting columns 21, a fixed Bar 22, connection block 23, first cylinder 24, second cylinder 27 and solder pen 25, a pair of said support columns 21 are arranged oppositely at both ends of workbench 11 respectively, and said fixing strip 22 is arranged on a pair of support columns 21 Between the top, the fixed bar 22 is provided with a guide rail 221, and the connecting block 23 is slidably connected with the guide rail 221. The second cylinder 27 is arranged on the side of the supporting column 21, and is connected to the connecting block 23 through the second piston rod 271. The side is connected, and the other side of the connecting block 23 is provided with a first cylinder 24, and the solder pen 25 is connected with the fir...

Embodiment 2

[0035] Such as Figure 1-3As shown, an automatic soldering device for a multimedia interface line includes a frame 1, a soldering part 2 and a placement part 3, the frame 1 is provided with a workbench 11, and the soldering part 2 includes a pair of supporting columns 21, a fixed Bar 22, connection block 23, first cylinder 24, second cylinder 27 and solder pen 25, a pair of said support columns 21 are arranged oppositely at both ends of workbench 11 respectively, and said fixing strip 22 is arranged on a pair of support columns 21 Between the top, the fixed bar 22 is provided with a guide rail 221, and the connecting block 23 is slidably connected with the guide rail 221. The second cylinder 27 is arranged on the side of the supporting column 21, and is connected to the connecting block 23 through the second piston rod 271. The side is connected, and the other side of the connecting block 23 is provided with a first cylinder 24, and the solder pen 25 is connected with the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com