Electric soldering iron robot capable of realizing rapid tin soldering

An electric soldering iron and robot technology, applied in tin feeding devices, welding equipment, auxiliary devices, etc., can solve the problems of labor-consuming manual soldering and slow soldering progress, and achieve the effect of improving soldering efficiency, ensuring soldering volume and soldering uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

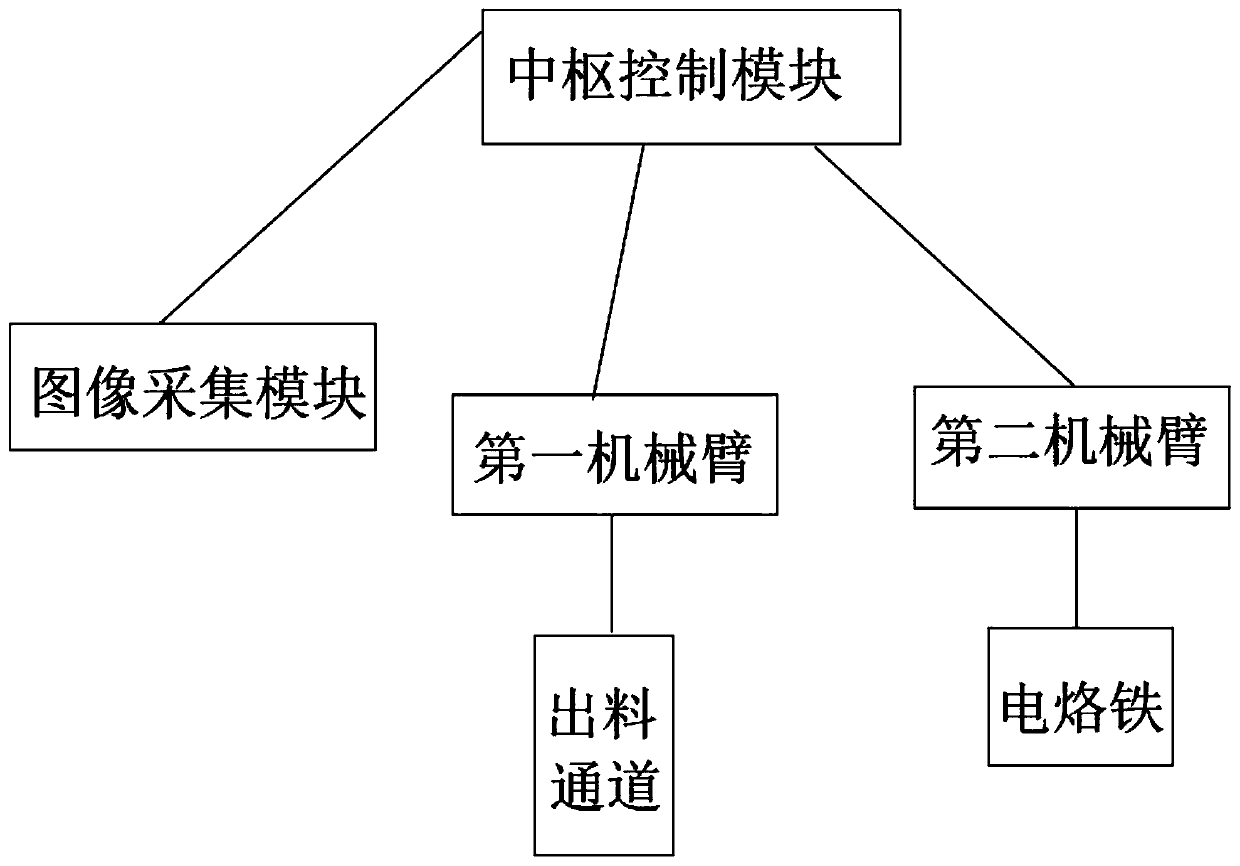

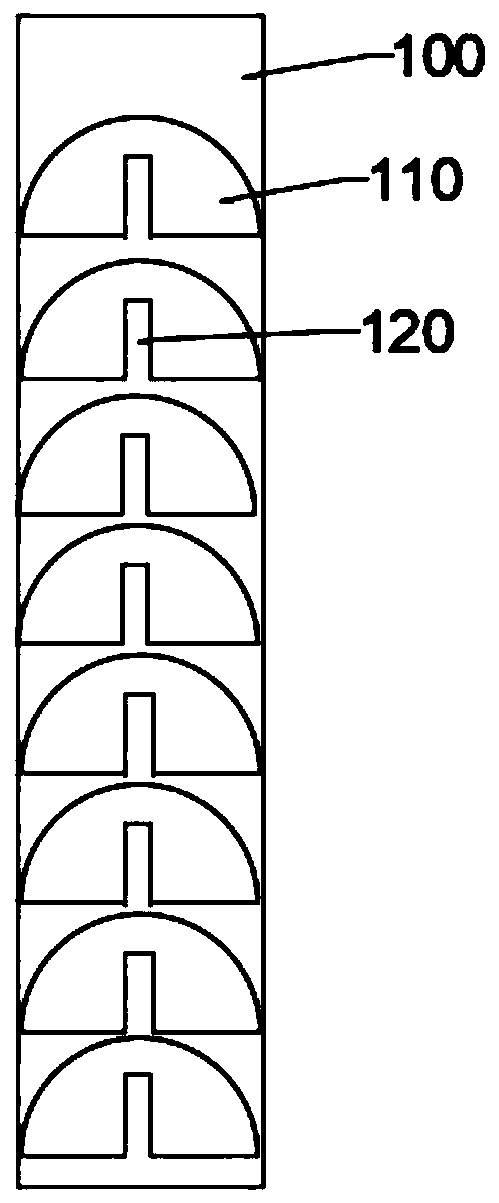

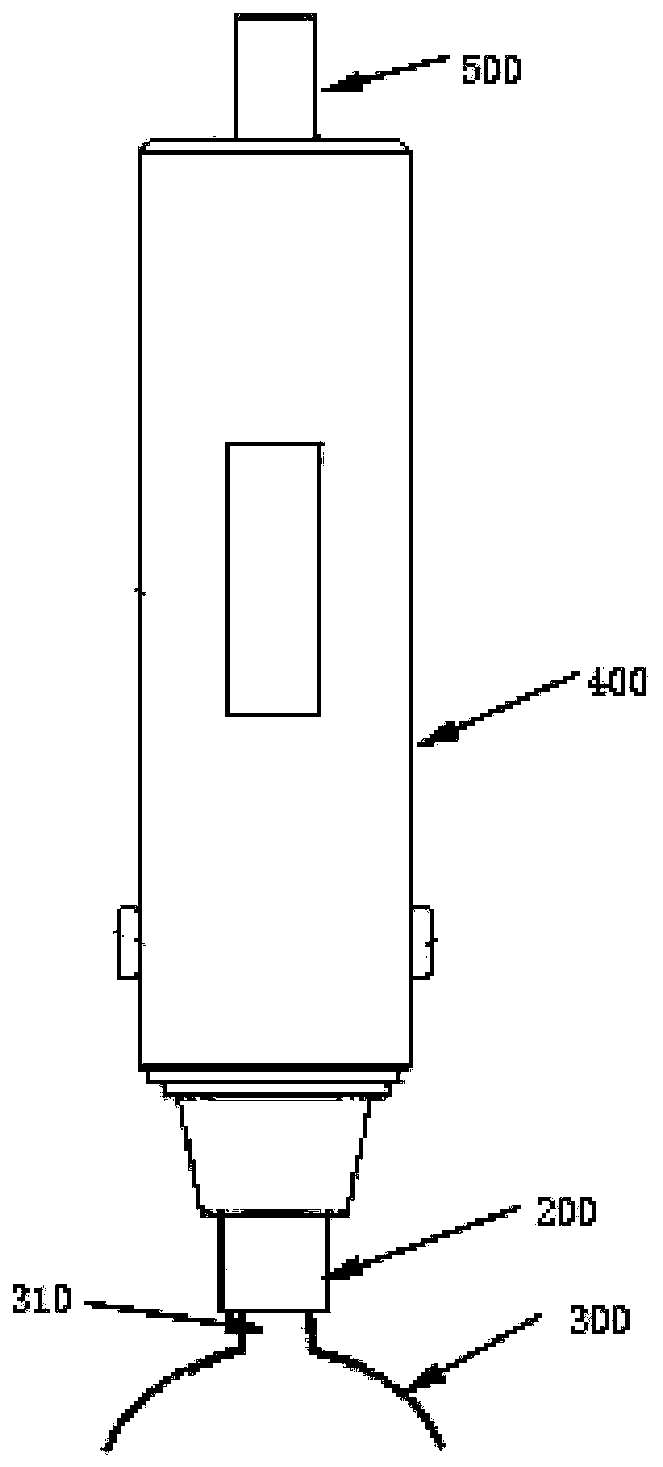

[0028] Such as Figure 1~3 As shown, a fast soldering iron robot includes an image acquisition module, a central control module, a first mechanical arm and a second mechanical arm, the head of the first mechanical arm is provided with a discharge channel 100, and the discharge Solder material 110 is placed in the channel 100, the head of the second mechanical arm is provided with an electric soldering iron, and the image acquisition device collects component pins on the circuit board, and transmits the collected pin position information to the central control Module, the first mechanical arm and the second mechanical arm of the central control module move, the first mechanical arm puts the solder material 110 on the pin position, and the electric soldering iron of the second mechanical arm heats and melts the solder material 110 to realize welding.

[0029] In the technical solution, the soldering is realized by the electric soldering iron robot, without manual soldering, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com