A high-efficiency LED lamp chip soldering equipment based on digital linear dimming technology

A LED lamp, digital linear technology, applied in welding equipment, metal processing equipment, tin feeding device, etc., can solve problems affecting welding efficiency, tin outflow difficulties, etc., achieve good soldering effect, simple structure, full and firm solder joints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

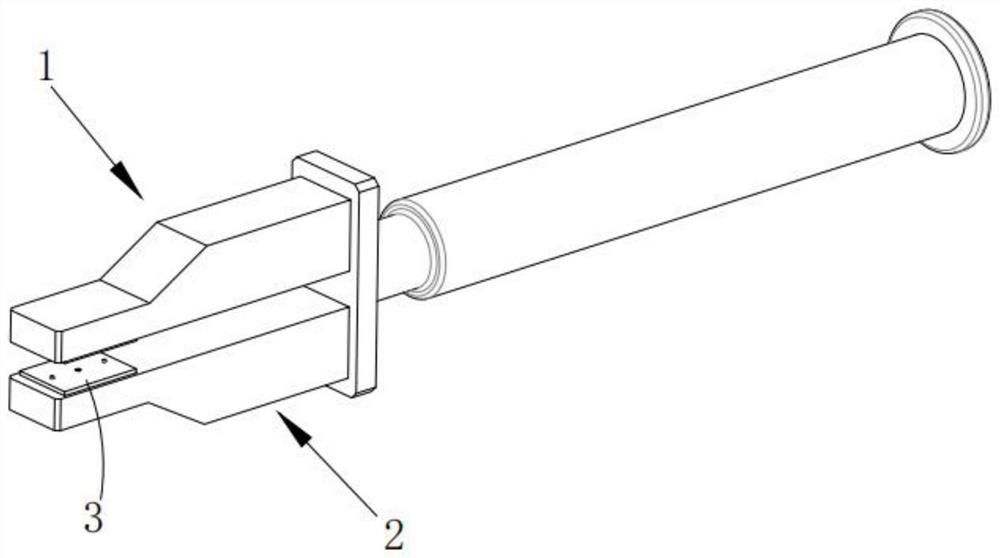

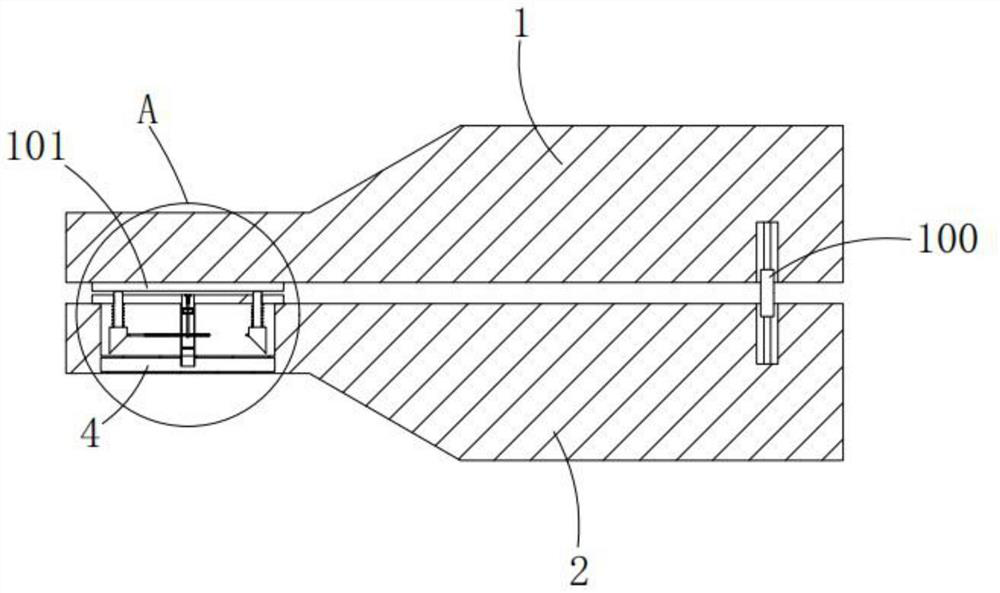

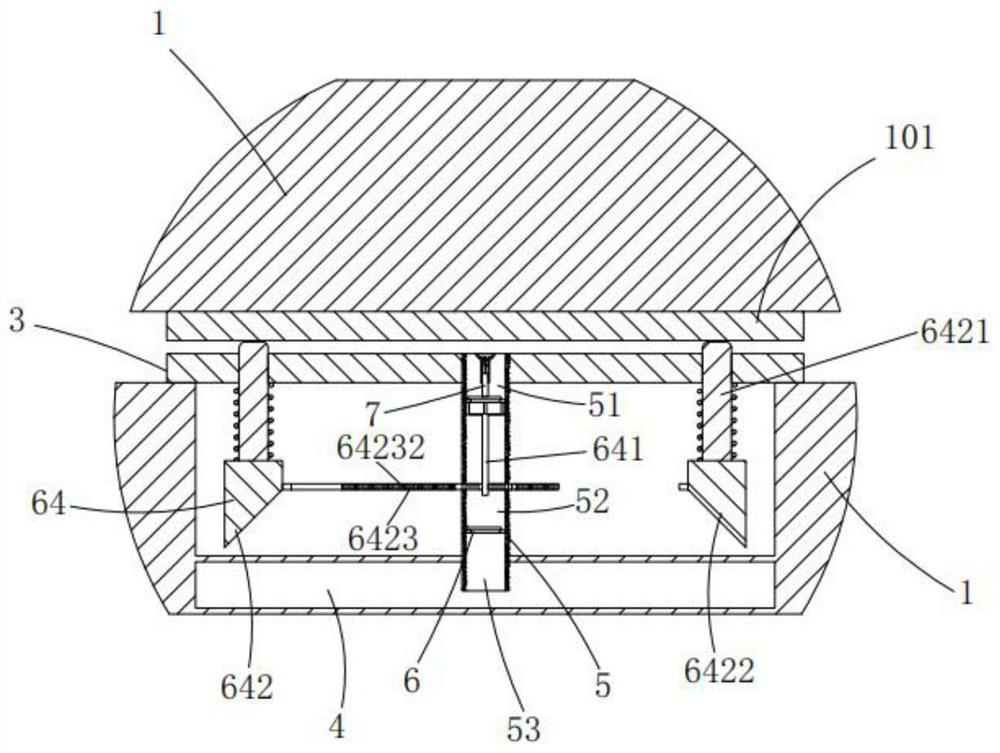

[0037] like Figure 1 to Figure 3 As shown in the figure, a high-efficiency LED lamp chip soldering device based on digital linear dimming technology includes an upper collet 1 and a lower collet 2 that can be clamped and arranged, and the lower collet 2 is provided with a welding device for placing chips. Stage 3, a tin storage chamber 4 is arranged below the welding stage 3, and also includes:

[0038] A tin supply channel 5, the tin supply channel 5 runs through the soldering station 3 and extends downward into the tin storage chamber 4;

[0039] The conveying device 6 is arranged in the tin conveying channel 5 and divides the tin conveying channel 5 into a storage section 51, a temporary storage section 52 and a conveying section 53 from top to bottom. The tin in the tin storage chamber 4 enters the storage section 51 through the conveying section 53 and the temporary storage section 52 in sequence;

[0040] The tin feeding device 7, the tin feeding device 7 sends the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com