Mechanical arm sample injection module

A robotic arm and sample injection technology, applied in the direction of analyzing materials, instruments, etc., can solve problems such as inflexibility, bloated structure, and unsatisfactory robotic arm sampling modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

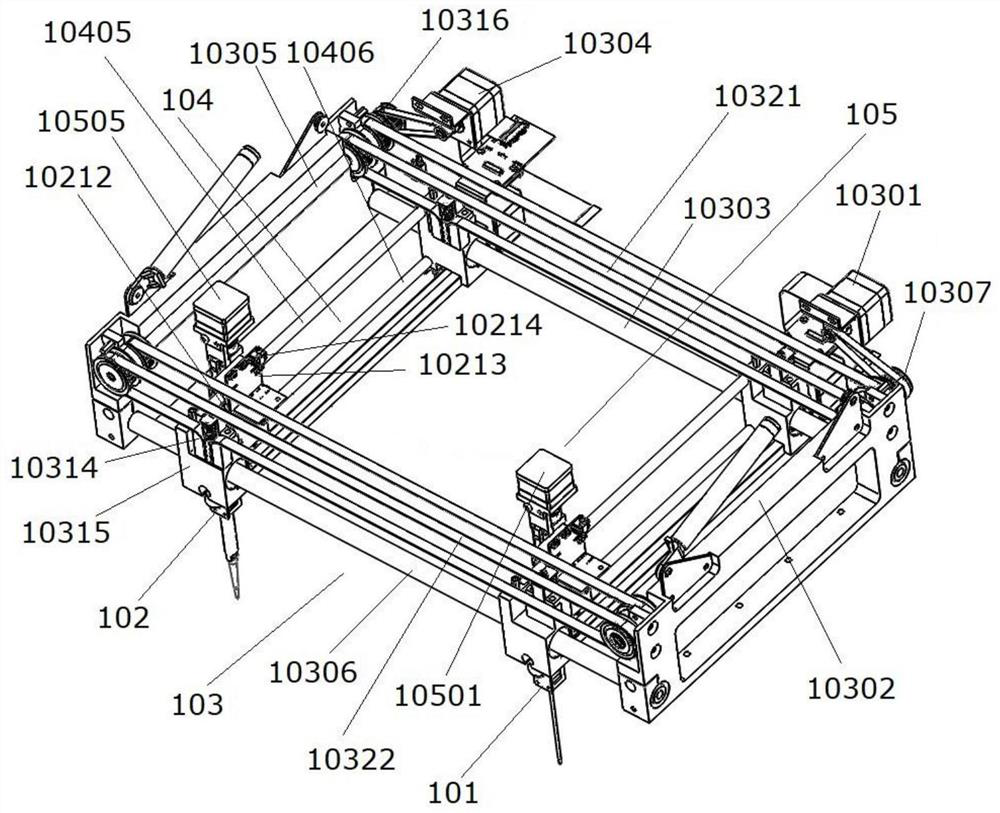

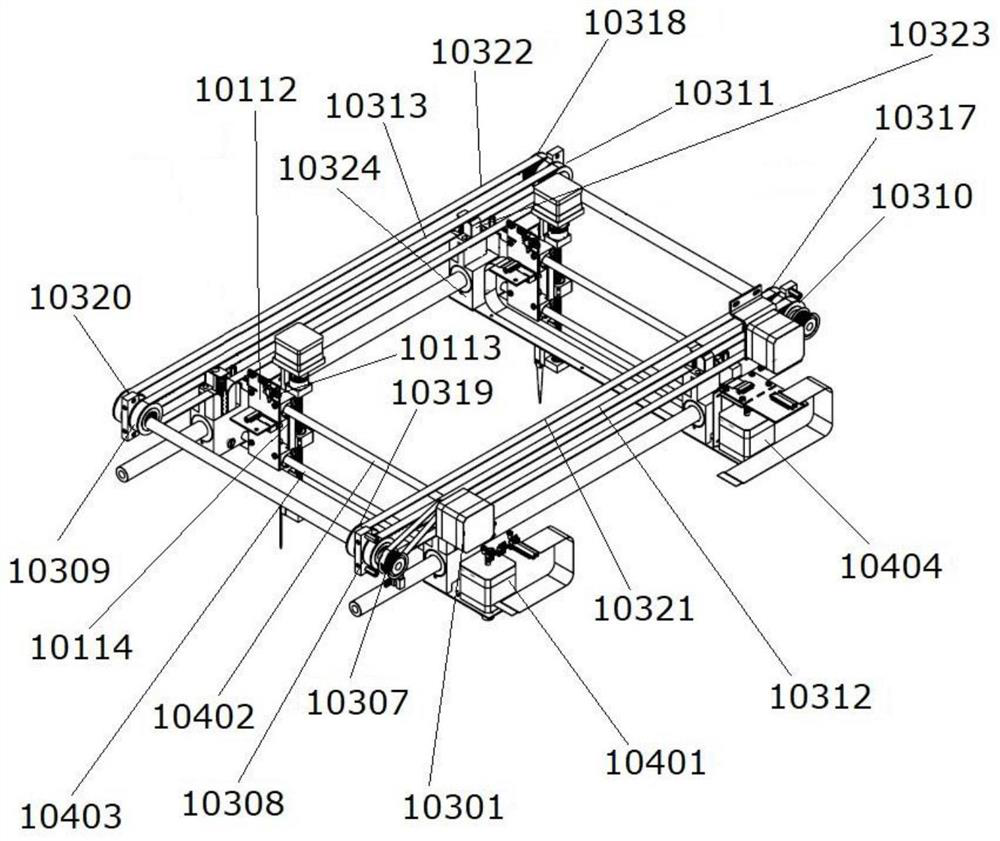

[0041] Such as figure 1 As shown, the robotic arm sampling module 3 includes a sampling device one 101 equipped with a sampling needle assembly 10101 and a sampling device two 102 equipped with a pipette tip assembly 10201; wherein the sampling device one 101 is used to absorb the reaction reagent In the cuvette 9, the sampling device 2 102 is used to draw a sample and add it to the cuvette 9; the mechanical arm sampling module 3 also includes a transverse movement assembly 103, a longitudinal movement assembly 104 and an up and down movement assembly 105, and the transverse The motion assembly 103 respectively drives the first sampling device 101 and the second sampling device 102 to move laterally, the longitudinal motion assembly 104 drives the first sampling device 101 and the second sampling device 102 to move longitudinally, and the vertical motion assembly 105 respectively Driving the first sampling device 101 and the second sampling device 102 to move up and down.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com