Winding Soldering Machine

A soldering machine and winding mechanism technology, applied in the direction of welding/welding/cutting items, electrical components, circuits, etc., can solve the problems of low efficiency, low yield, and inability to meet mass production, so as to reduce labor costs, winding The integrated guarantee of wire soldering and the effect of improving soldering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

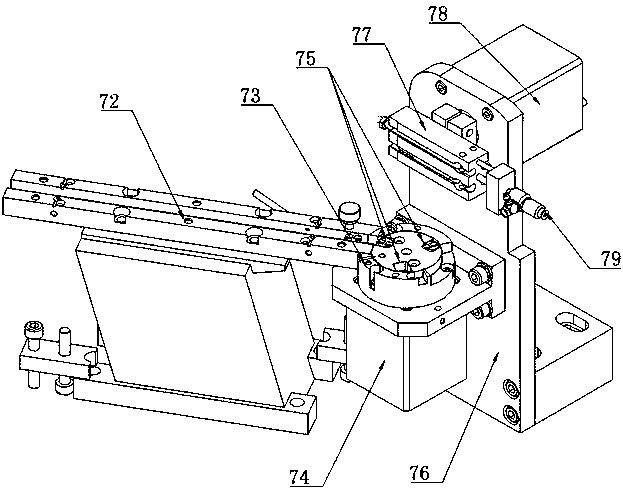

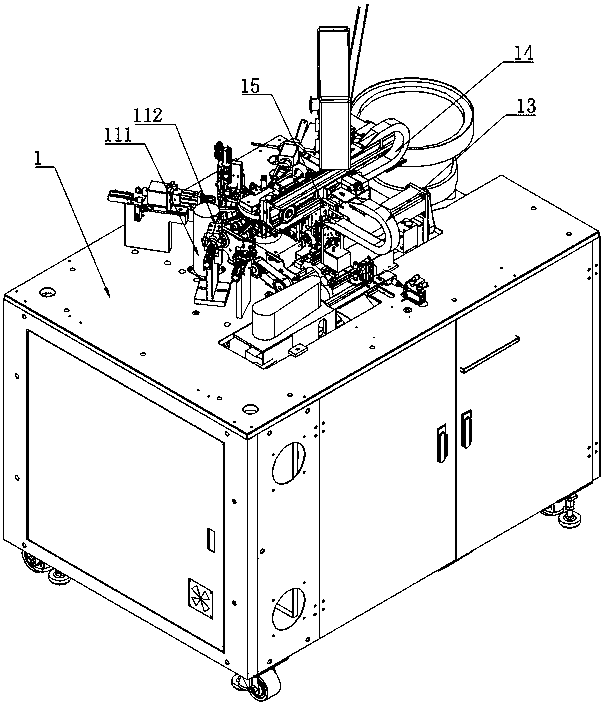

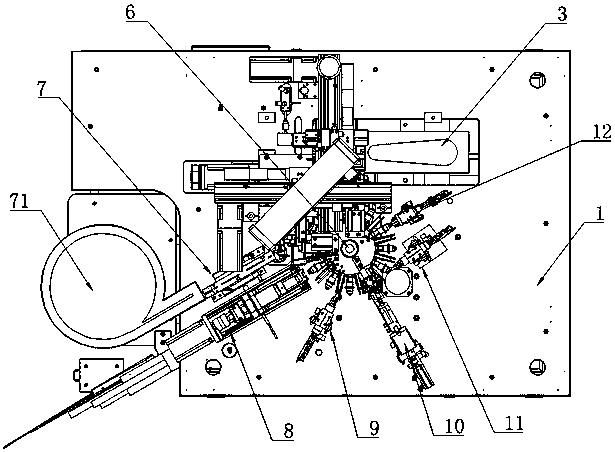

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a workbench 1, a winding mechanism arranged on the workbench 1 and a soldering mechanism arranged on one side of the winding mechanism, and the soldering mechanism includes a The transmission device, the discharge runner 2 connected with the transmission device, and the wave crest tin furnace 3 arranged on one side of the discharge runner 2, on the discharge runner 2 are evenly arranged several in-line The discharge tank 4 is also provided with the flux tank 5 which communicates with the wave peak tin furnace 3 and contacts the in-line discharge tank 4 below the discharge runner 2, A reclaiming mechanical arm is also arranged above the wheel 2. Adsorption magnetic strips are placed in the in-line discharge tank 4, and the products that have completed the previous process are sequentially arranged on the in-line discharge tank 4, and the transmission device is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com