Process method for carrying out integral soldering on armature

A process method and integral welding technology, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of unsatisfactory sealing effect of asbestos rope, low welding reliability, and affecting the quality of motors, etc., so as to enhance the reliability of soldering performance, improve anti-oxidation ability, and increase the effect of repeated use times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

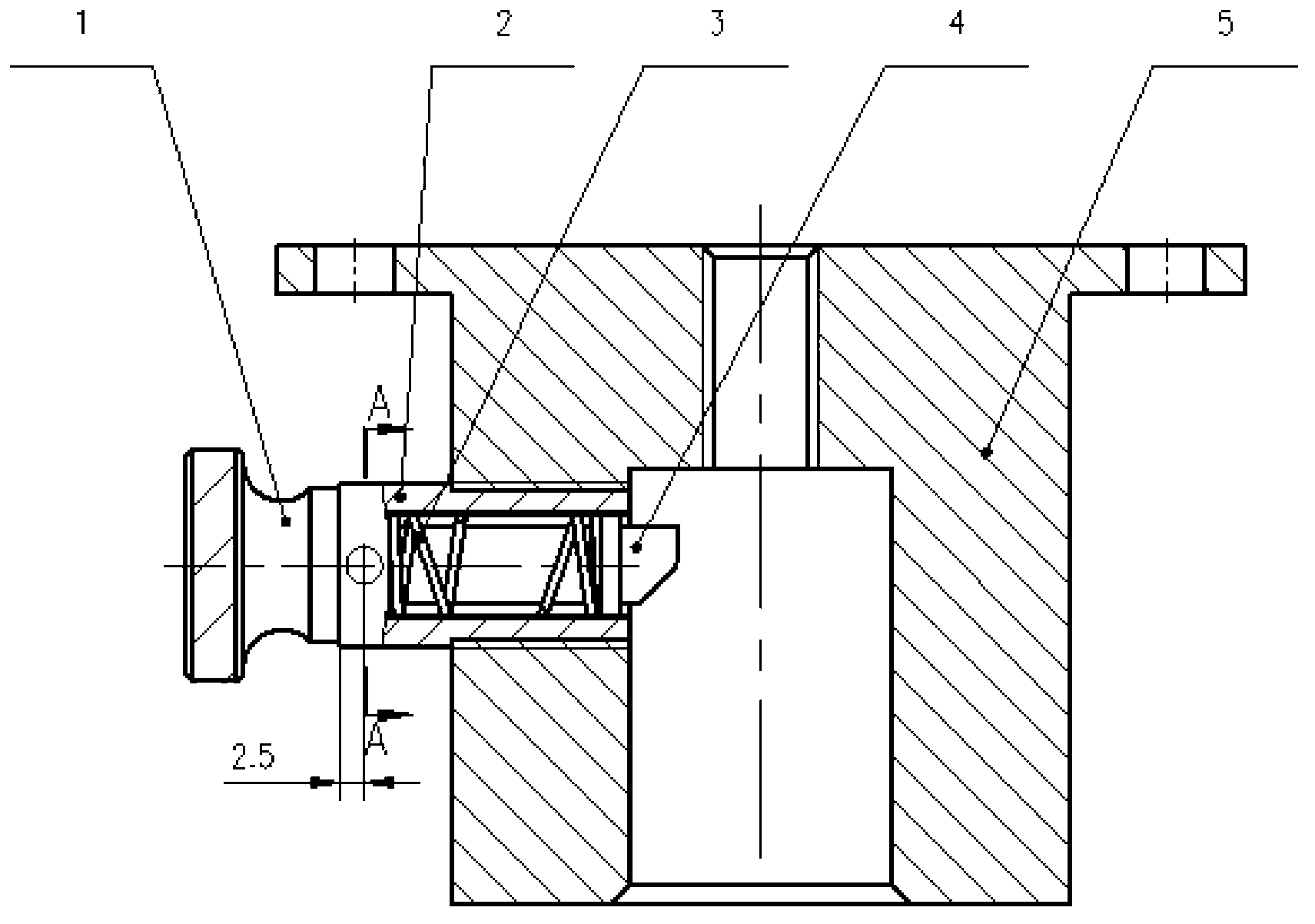

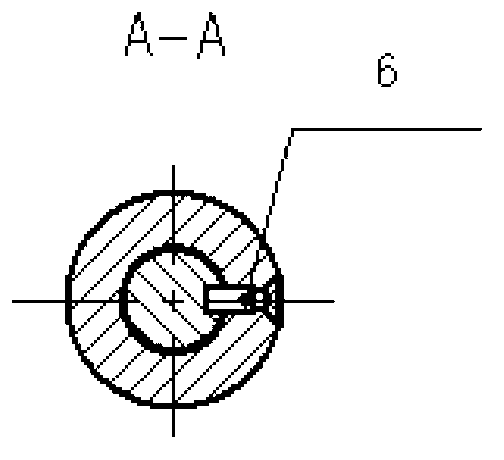

[0015] The technological method of the integral soldering of the armature is an innovation based on the traditional integral dip welding process of the armature winding and the commutator, and belongs to the invention of the technological method.

[0016] Technical scheme of the present invention is:

[0017] 1. The pre-tinning process of the commutator is added before the overall soldering of the armature;

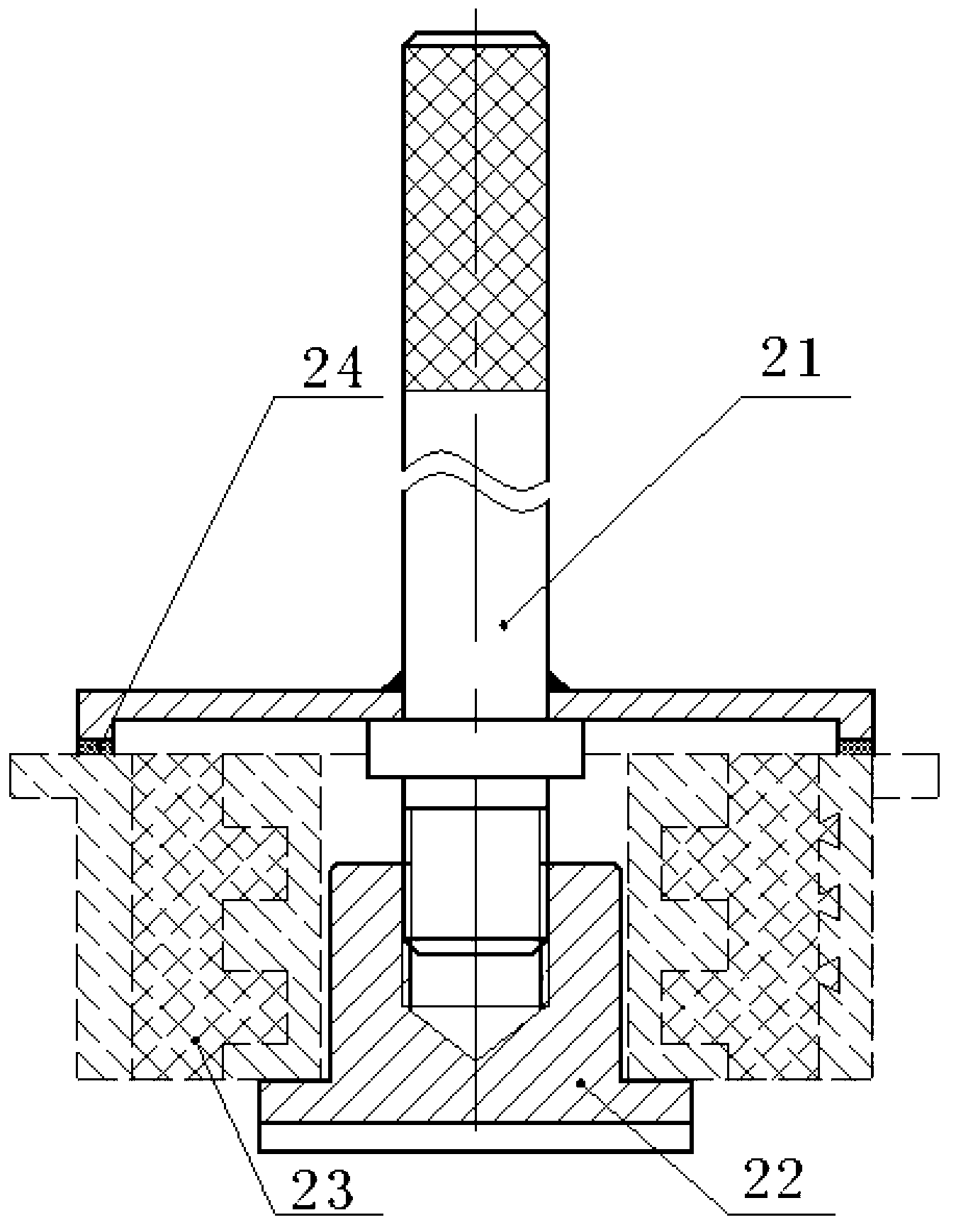

[0018] 2. By using metal wound gaskets instead of asbestos ropes.

[0019] 3. Among them, the temperature control and maintenance of the tin pot in the overall solder of the armature affects the state of the molten tin in the tin pot, and the state of the molten tin directly affects the quality of the overall solder of the armature. As another improvement of the present invention, a tin pot is made of titanium alloy, and a PID intelligent controller is used for temperature control and maintenance. When the titanium alloy tin pot is used, the anti-oxidation ability of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com