Automatic wire laser soldering machine

A soldering machine and wire technology, used in welding equipment, tin feeding devices, manufacturing tools, etc., can solve the problems of slow processing efficiency, small focusing spot, small heat affected zone, etc., to avoid the influence of solder quality and high soldering efficiency. , to avoid the effect of instantaneous heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

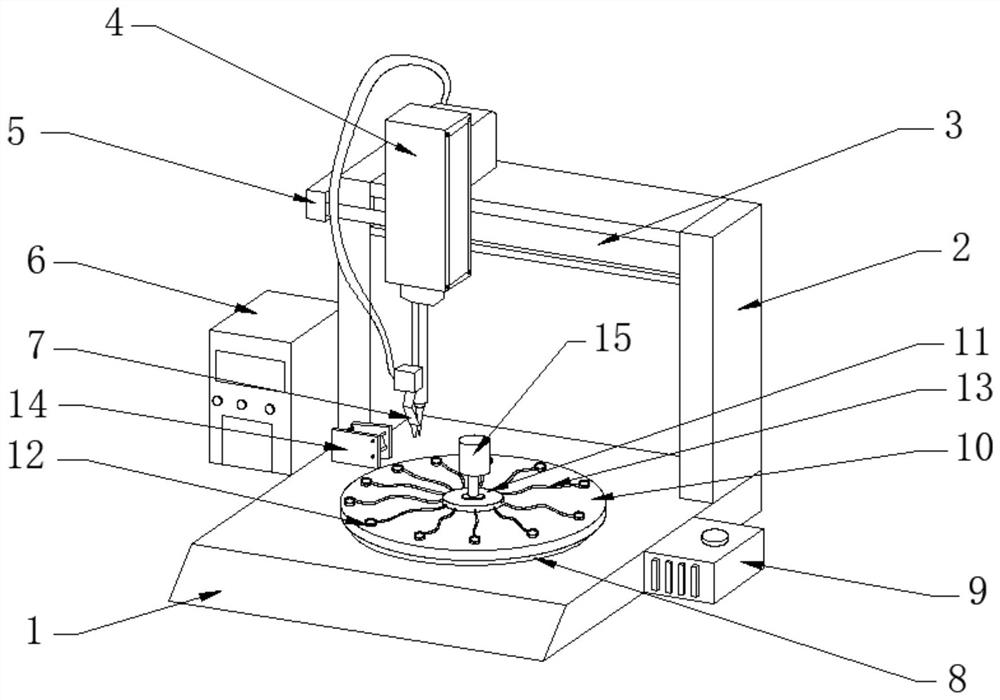

[0018] Such as figure 1 As shown, the present invention provides an automatic wire laser soldering machine, including a machine base 1, a fixed frame 2 is fixedly installed on the machine base 1, a slide rail 3 is arranged on the fixed frame 2, and a laser generator is slidably installed on the slide rail 3 4. A horizontal telescopic motor 5 is installed on the outside of the fixed frame 2, a control cabinet 6 is fixedly installed on the outside of the machine base 1, the bottom end of the laser generator 4 is connected with a laser welding head 7 through a wire, and the central surface of the machine base 1 is installed with a Turntable 8, drive motor 9 is connected to the outer side of turntable 8, workpiece disk 10 is fixedly installed on the top of turntable 8, solder paste pot 11 is installed on the central surface of workpiece disk 10, and several solder joint grooves are arranged at the edge of workpiece disk 10 12. The solder joint groove 12 and the solder paste tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com