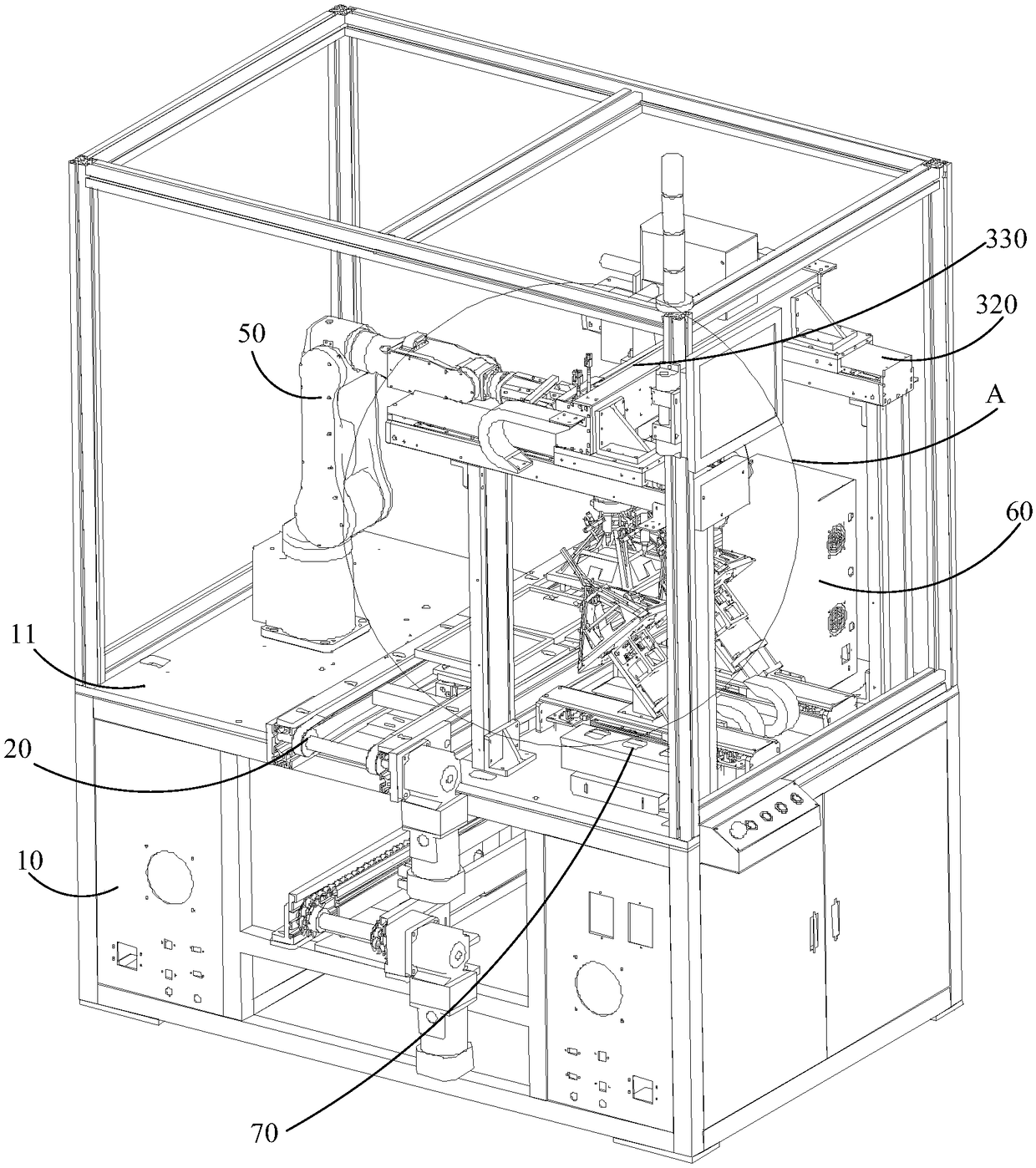

Ring vibrator automatic soldering robot and control method thereof

An automatic welding and robot technology, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of low production efficiency, failure to meet the communication market, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

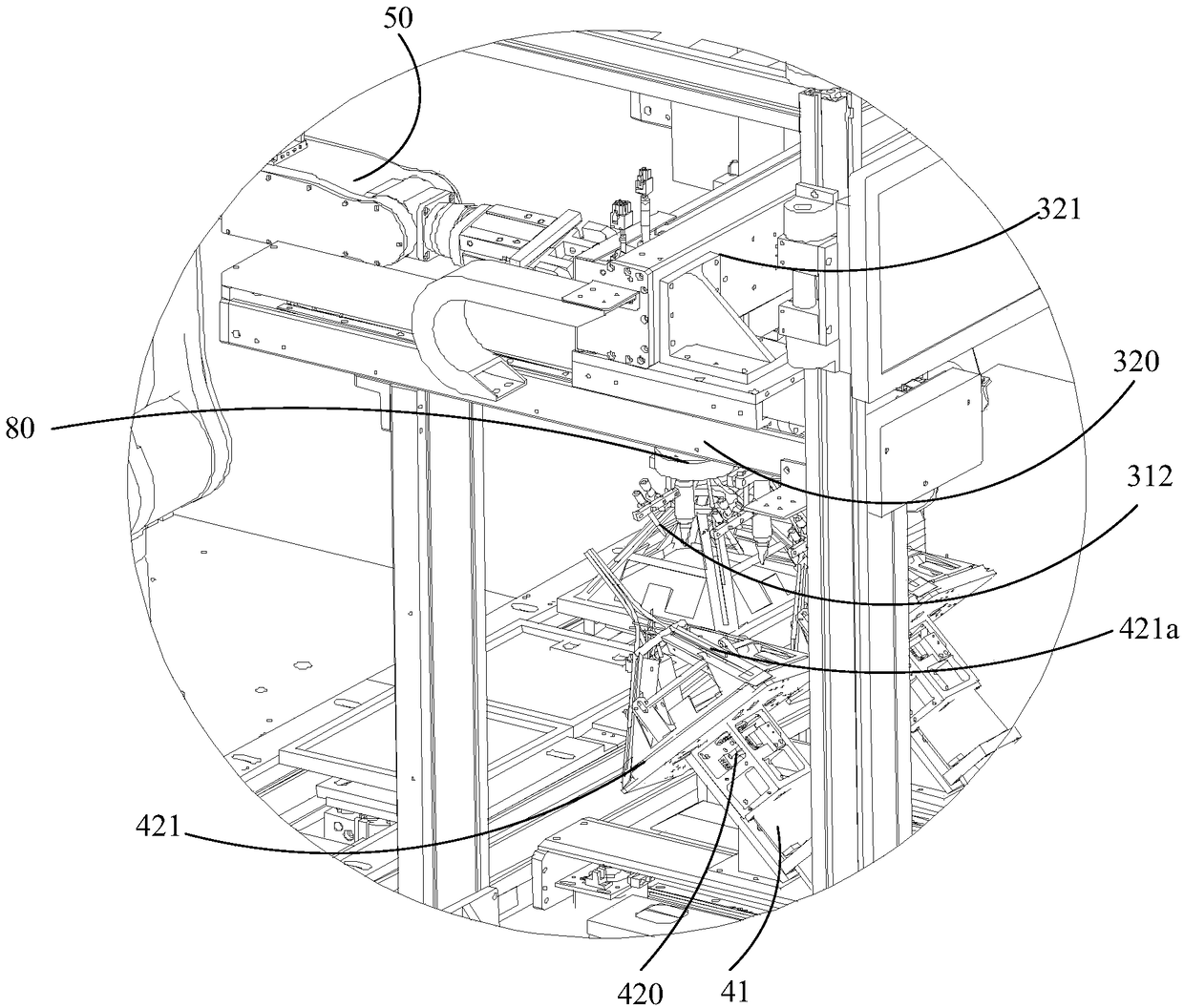

Method used

Image

Examples

no. 1 example

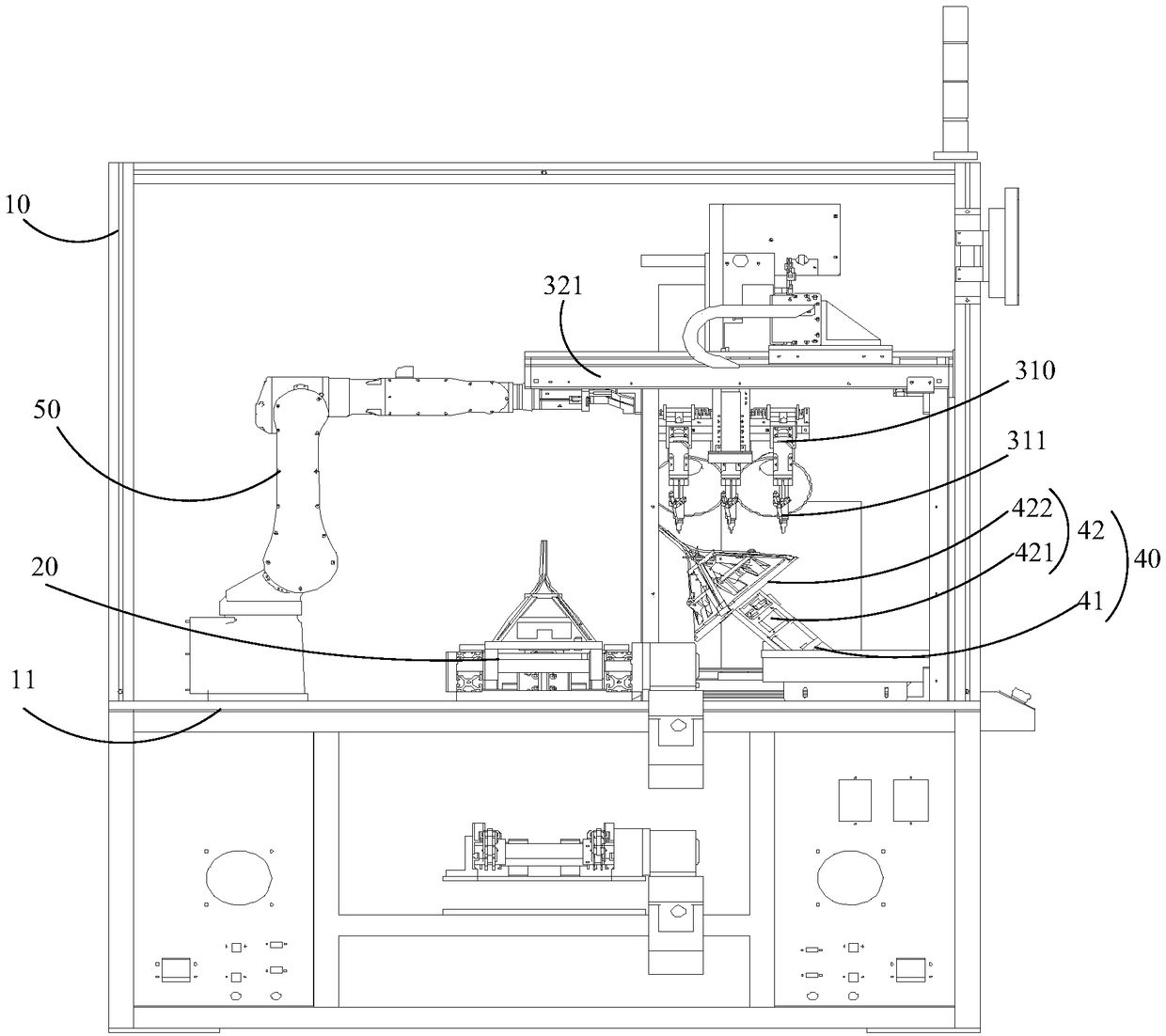

[0057] refer to Image 6 , the present invention also proposes a first embodiment of a control method of a ring vibrator automatic soldering robot. In this embodiment, the control method of the ring vibrator automatic soldering robot includes the following steps:

[0058] S10: when the workpiece to be processed is transferred to the loading position corresponding to the manipulator 50, control the manipulator 50 to grab the workpiece to be processed from the loading position and place it on the rotating support 42;

[0059] In this embodiment, the ring vibrator automatic soldering robot is provided with an industrial computer, and the control cabinet and the industrial computer installed in the control cabinet are arranged on the frame; in one embodiment, the industrial computer and the transmission device 20, The solder assembly 31, the workpiece fixing device 40, and the manipulator 50 are electrically connected, and an action command is sent to the above-mentioned devices, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com