Low-splash and halogen-free welding agent for tin wires and preparation method thereof

A technology of tin wire and soldering powder, which is applied in the formulation and preparation of soldering powder, can solve the problems of immune system, endocrine system poisoning, affecting the reproduction and development of organisms, corrosiveness, etc., and achieves good wettability and reliability High performance and high surface insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

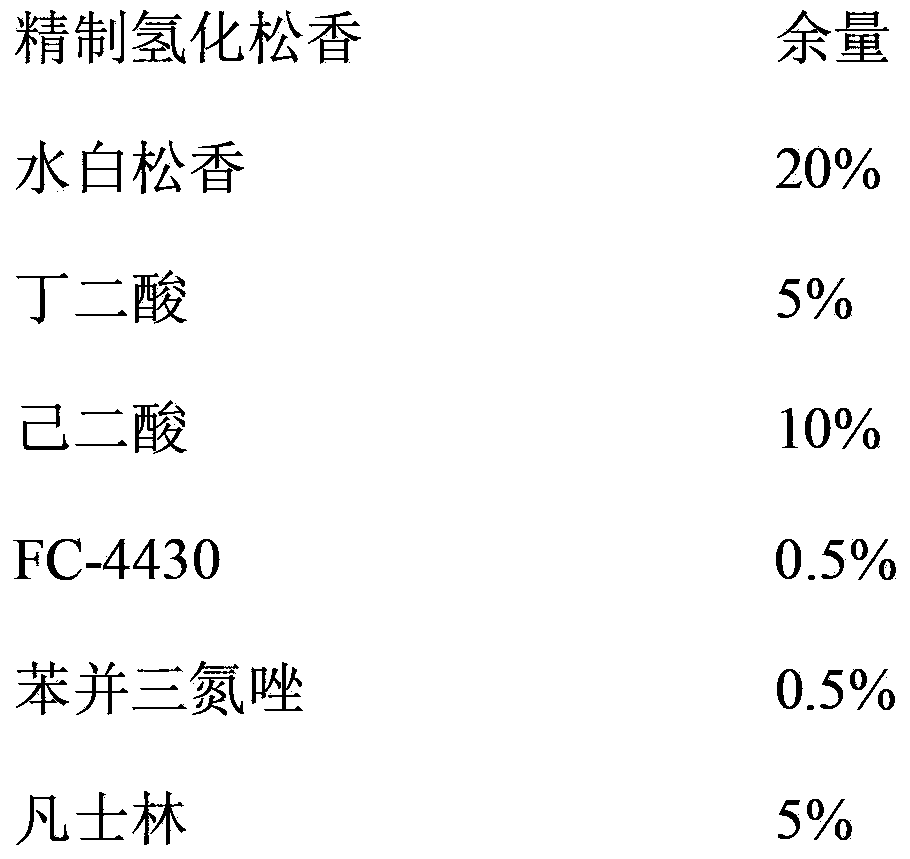

[0017]

[0018] (1) Add the refined hydrogenated rosin and water-white rosin into the reaction kettle, heat to 140°C until they are completely melted;

[0019] (2) Add succinic acid, adipic acid, FC-4430, benzotriazole and petrolatum in sequence;

[0020] (3) Stir continuously until all components are completely dissolved.

Embodiment 2

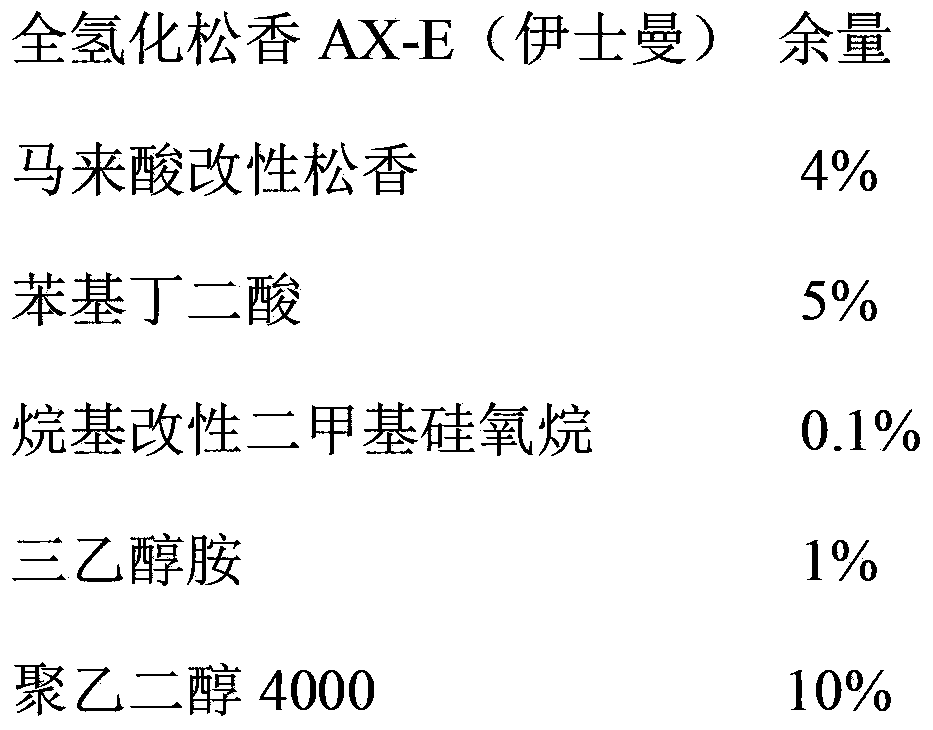

[0022]

[0023] (1) Add fully hydrogenated rosin AX-E (Eastman) and maleic acid-modified rosin into the reaction kettle, heat to 140°C until completely melted;

[0024] (2) Add phenylsuccinic acid, alkyl modified dimethyl siloxane, triethanolamine and polyethylene glycol 4000 in sequence;

[0025] (3) Stir continuously until all components are completely dissolved.

Embodiment 3

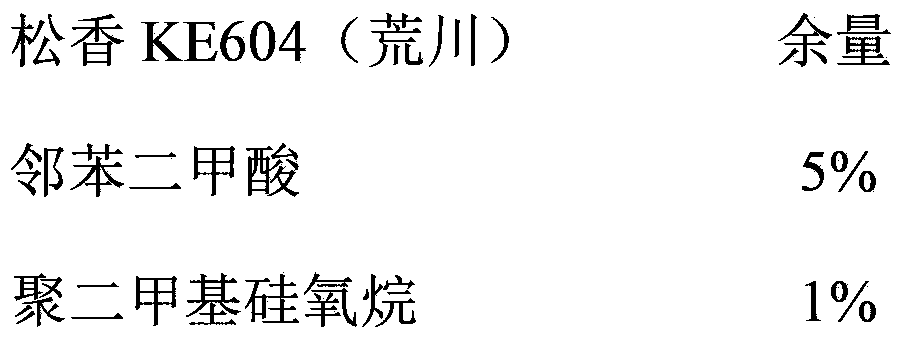

[0027]

[0028]

[0029] (1) Add rosin KE604 (Arakawa) into the reaction kettle, heat to 140°C until all melted;

[0030] (2) Add phthalic acid, polydimethylsiloxane, 2-ethylimidazole and polyethylene glycol 6000 in sequence;

[0031] (3) Stir continuously until all components are completely dissolved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com