Patents

Literature

47results about How to "Bright spot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

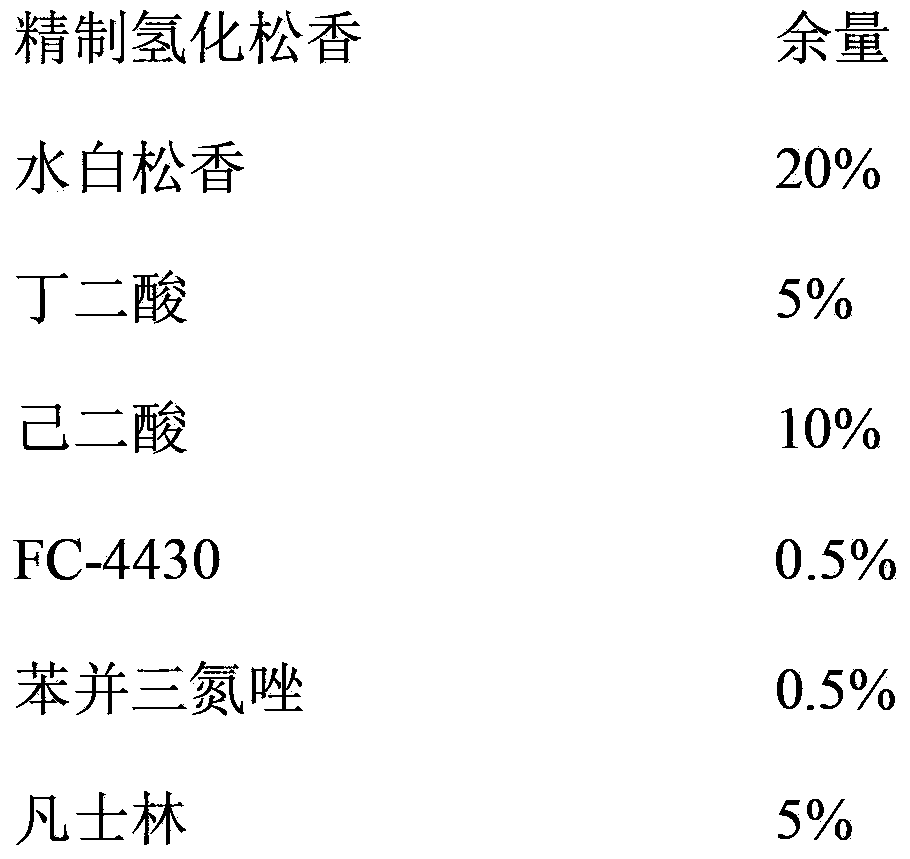

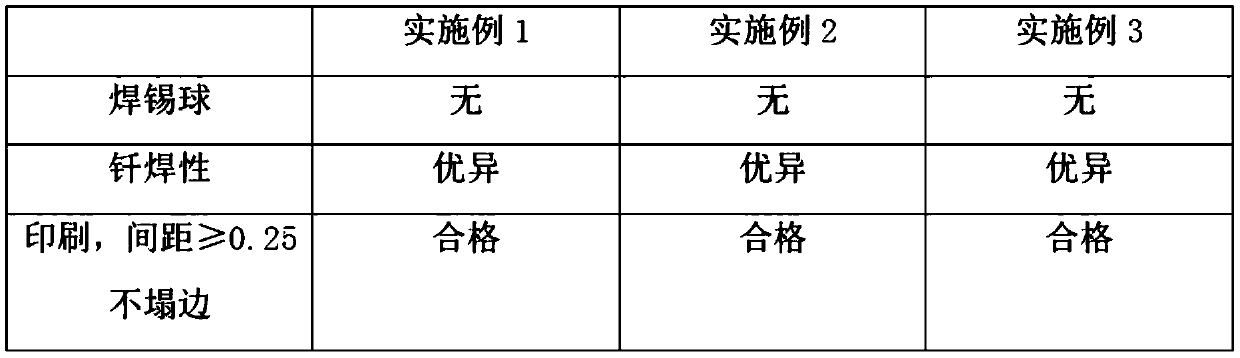

Soldering flux in use for SnZn series solder with no lead, and preparation method

InactiveCN101003111ABright spotGood formabilityWelding/cutting media/materialsSoldering mediaSolventRosin

Owner:DALIAN UNIV OF TECH

Halogen-free lead-free tin wire

InactiveCN102248317AImprove reliabilitySolder joints are fullWelding/cutting media/materialsSoldering mediaOrganic solventHalogen

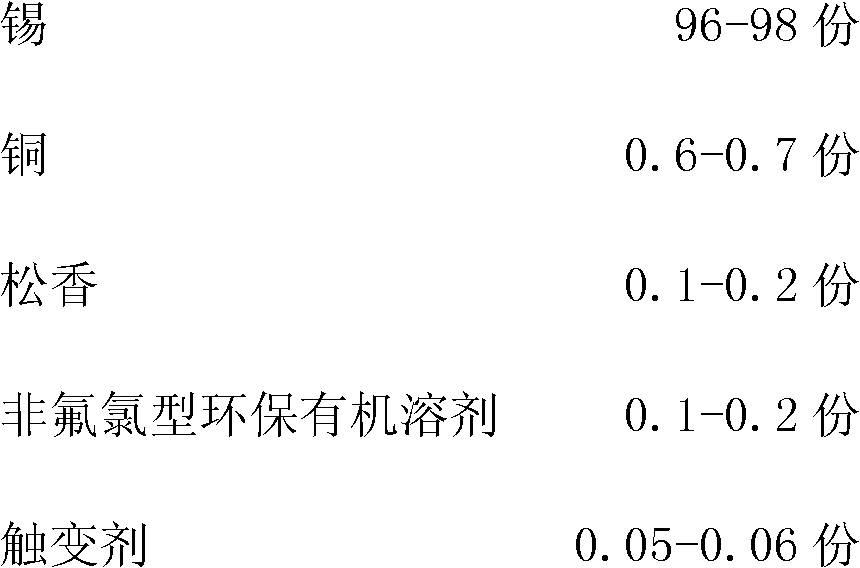

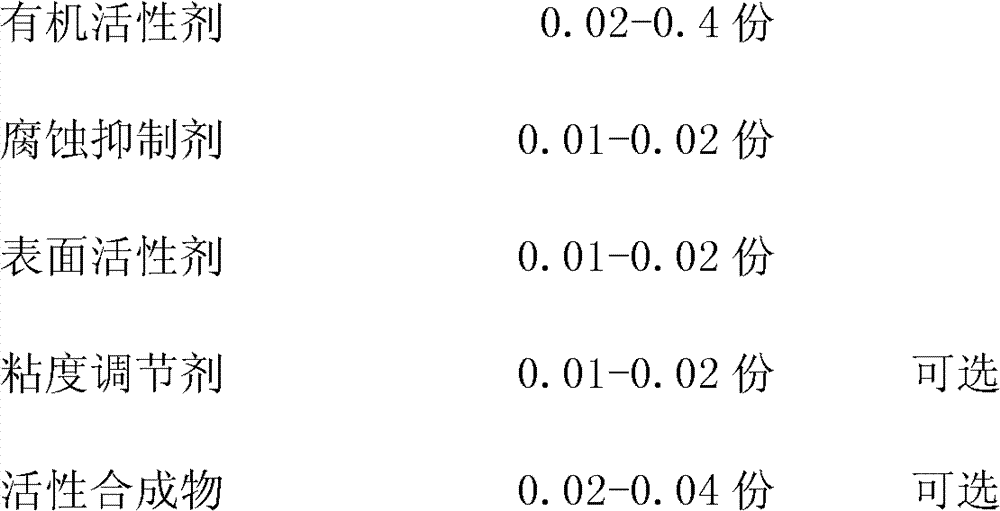

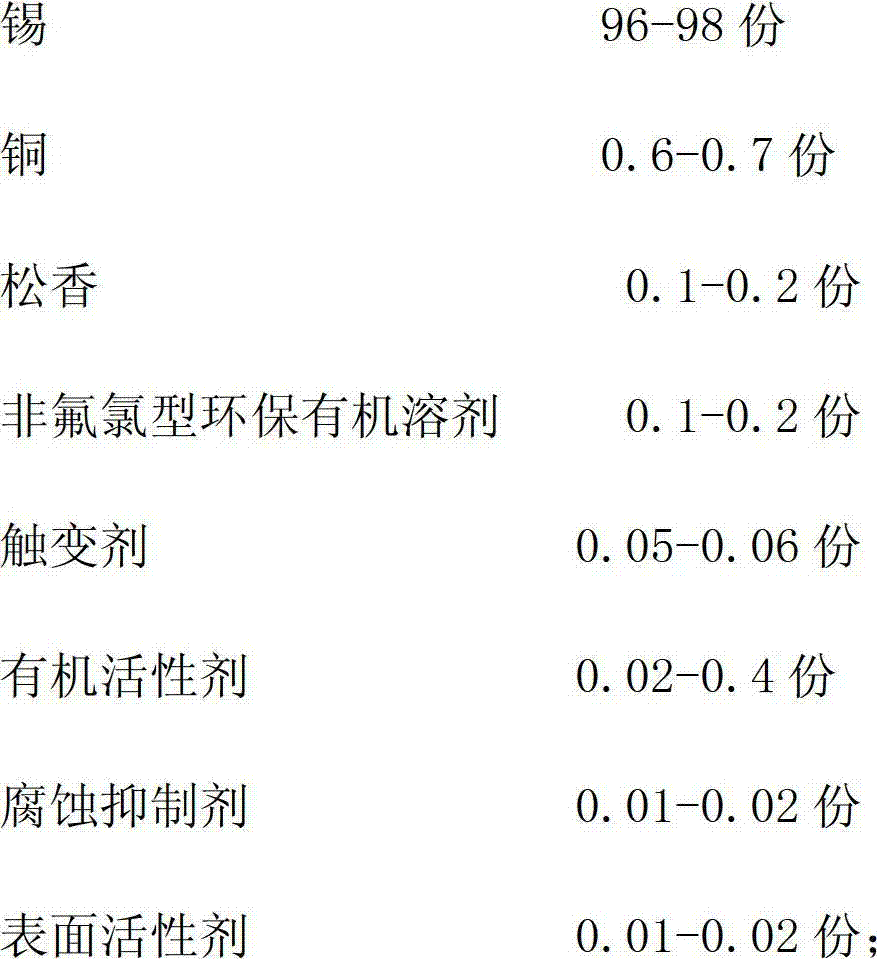

The invention relates to the technical field of tin wires, in particular to a composite halogen-free lead-free tin wire in line with the EU (European Union) directive. The tin wires comprise the following components in parts by per unit mass: 96-98 parts of tin, 0.6-0.7 part of copper, 0.1-0.2 part of resin, 0.1-0.2 part of non-fluorochloro environmentally-friendly organic solvent, 0.05-0.06 part of thixotropic agnet, 0.02-0.4 part of organic active agent, 0.01-0.02 part of corrosion inhibitor, and 0.01-0.02 part of surfactant, wherein the tin and the copper are the solder of the tin wire, and others are soldering flux. By using said technical scheme in the invention, the product is in line with relative directive of the EU and free from lead and relative halogen. Furthermore, the reliability of the welding is high, bad welding spot cannot be formed, and the welding spot is full and bright.

Owner:JIANGXI UNIV OF SCI & TECH +1

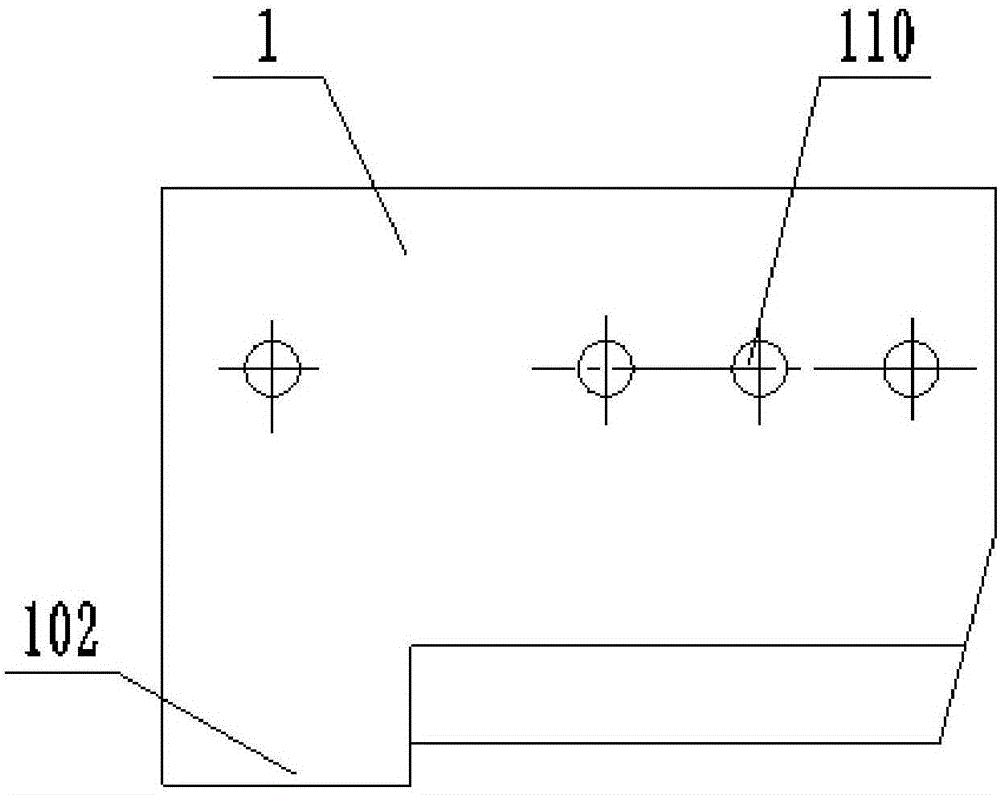

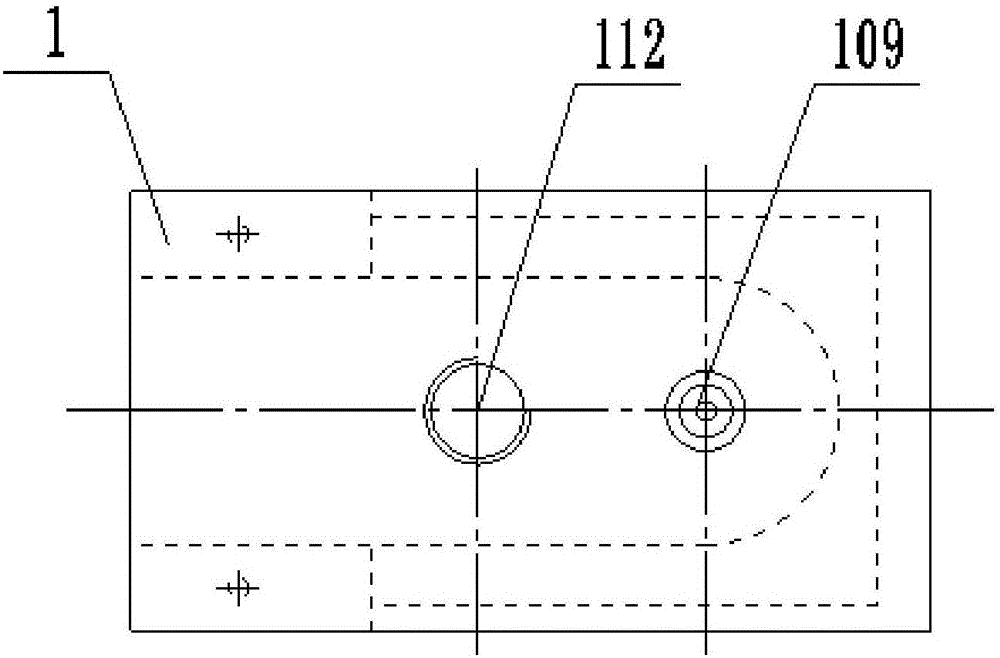

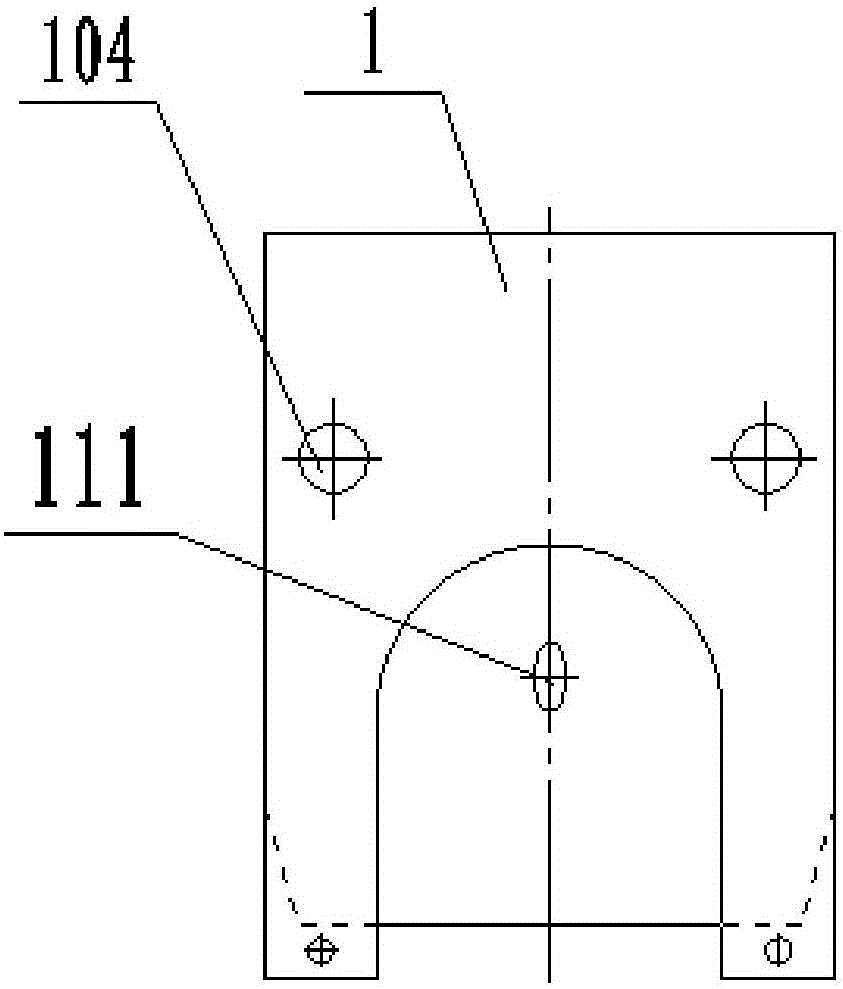

Air conditioner liquid storage device welding protection device and application method thereof

ActiveCN106270915AAvoid oxidation and blackeningAvoid contactGas flame welding apparatusSurface oxidationEngineering

The invention discloses an air conditioner liquid storage device welding protection device and an application method thereof, and belongs to the technical field of welding. The air conditioner liquid storage device welding protection device comprises an outer ventilation block and an inner ventilation block. The outer ventilation block is of a rectangular block-shaped structure and is provided with a transverse air blowing hole and longitudinal air blowing holes and connected with an air source through an outer ventilation connecting hole. An inner air blowing hole is formed in the inner ventilation block and connected with the air source through an inner ventilation connecting hole. According to the method, a cylinder is inflated with protection air through the inner ventilation block in the welding process, the welding position is immediately inflated with the protection air through the outer ventilation block after welding is finished, and air is prevented from making contact with a welding line. By means of the air conditioner liquid storage device welding protection device and the application method thereof, the surface of a welded part can be prevented from being oxidized during liquid storage device welding, the connecting strength of the welding line is improved, the quality of a finished product is improved, and the production cost is reduced.

Owner:ANHUI ZHONGHUI REFRIGERATION

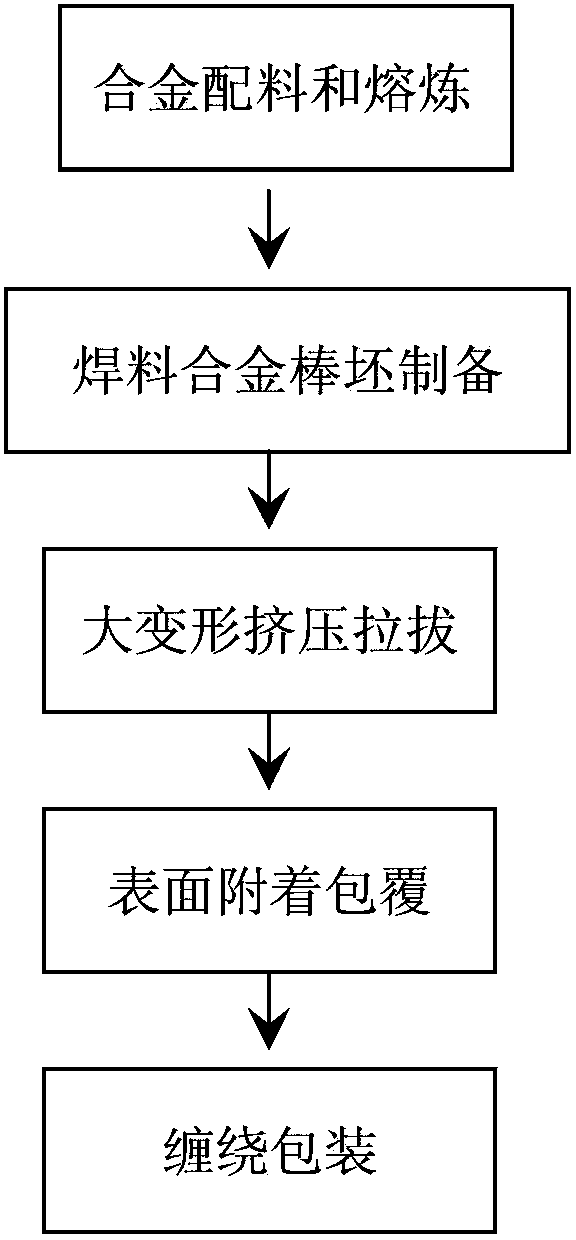

Anti-oxidation high-temperature soft-solder solid wire and manufacturing method thereof

InactiveCN104070303AImprove mechanical propertiesImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaManufacturing technologyConductor Coil

The invention relates to an anti-oxidation high-temperature soft-solder solid wire and a manufacturing method thereof and belongs to the technical field of solder production. The anti-oxidation solid wire comprises a high-temperature soft-solder solid wire and an anti-oxidation protective layer covering the solid wire. The high-temperature soft-solder solid wire comprises, by weight, Sn 2-15wt%, Ag 0-5wt%, one or multiple of P, Ge, Ga, Bi, Sb and Zn 0.01-1wt% and the balance Pb. Solder wires manufactured by the method effectively solve the problems such as black oxide of a surface layer of a lead-based solder, poor wetting during brazing without soldering flux and clamminess and damage to the surface of the solder wires in winding and use. The solder wires have the advantages of strong bonding strength, round welding spot, bright halation, good sealing performance, high reliability, long service life and the like in brazing and use.

Owner:BEIJING COMPO ADVANCED TECH

Low-splash and halogen-free welding agent for tin wires and preparation method thereof

InactiveCN103394824AHigh surface insulation resistanceImprove wettabilityWelding/cutting media/materialsSoldering mediaActive agentAlloy

The invention discloses a low-splash and halogen-free welding agent for tin wires and a preparation method thereof. The welding agent is mainly used for agent cores of tin-based alloy tin wires. The welding agent is composed of, by weight, 80-90% of rosin and rosin derivatives, 5-15% of active agents, 0.1-2% of efficient surface active agents, 0.5-2% of corrosion inhibitors and 3-10% of viscosity modifiers. The prepared halogen-free welding agent for the tin wires is needless of any halogen element, is little in splash and smoke when welding is conducted, has high activity, is high in surface insulation resistance, and can be used for preparing tin-lead series tin wires, tin-copper series tin wires and tin-silver-copper series tin wires. The prepared tin wires are good in wetting performance, high in reliability after being welded, and light and full in welding point.

Owner:BEIJING COMPO ADVANCED TECH

Lead-free solder

InactiveCN1806998AUniform metallographicMetallographic refinementWelding/cutting media/materialsSoldering mediaIndiumIntermediate frequency

The invention relates to a leadless tin soldering material which comprises the constituents (by mass ratio) of Ag 0.5-6%, Cu 0.1-2%, In 0.0001-1%, P 0.0001-1%, and balancing Sn. The preparing process of the soldering material comprises weighing 1.67-20 parts of Sn-Ag intermediate alloy ingot containing Ag 30%, 1-20 parts of Sn-Cu intermediate alloy ingot containing Cu 30%, 0.002-20 parts of Sn-In intermediate alloy ingot containing In 5%, P 0.0001-1 part, and balancing Sn in the whole 100 parts, charging the raw materials into manganese alloy crucible, smelting in intermediate frequency furnaces, evacuating and filling in nitrogen, elevating the temperature to 450 deg. C, agitating 1 hour, cooling down slowly and homogeneously to 340 deg C, charging weighed P and stirring homogeneously, finally pouring the melted liquid into dies.

Owner:THOUSAND ISLAND METAL FOIL

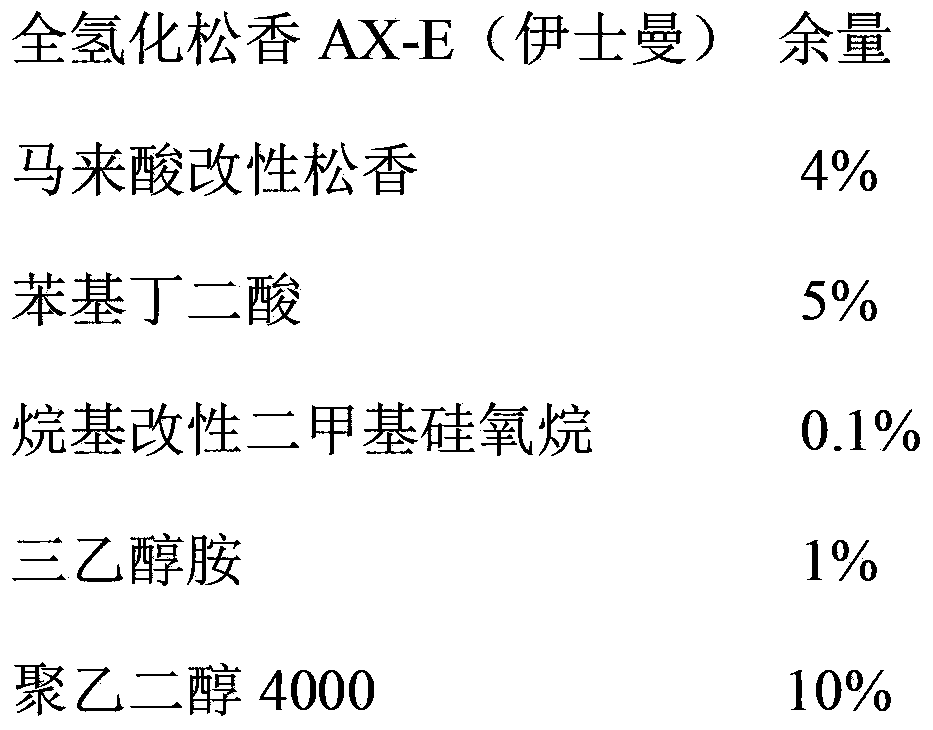

Rosin used for scaling powder as well as preparation method and application

ActiveCN106634612AImprove solubilityHigh flux activityWelding/cutting media/materialsNatural resin chemical modificationSolubilityHeat stability

The invention relates to rosin used for scaling powder as well as a preparation method and application, belonging to the field of basic resin used for the scaling powder. Rosin which contains mercusicacid is taken as a raw material to prepare the rosin used for the scaling powder. The rosin used for the scaling powder has excellent solubility and crystallization resistance in a scaling powder solvent system, is high in weld-aid activity and low in corrosivity, and has very good wettability for brazing filler metal free of lead; and the rosin used for the scaling powder is good in both heat stability and film-forming property, and the formed welding spot is full, bright and regular.

Owner:广东科茂林产化工股份有限公司 +2

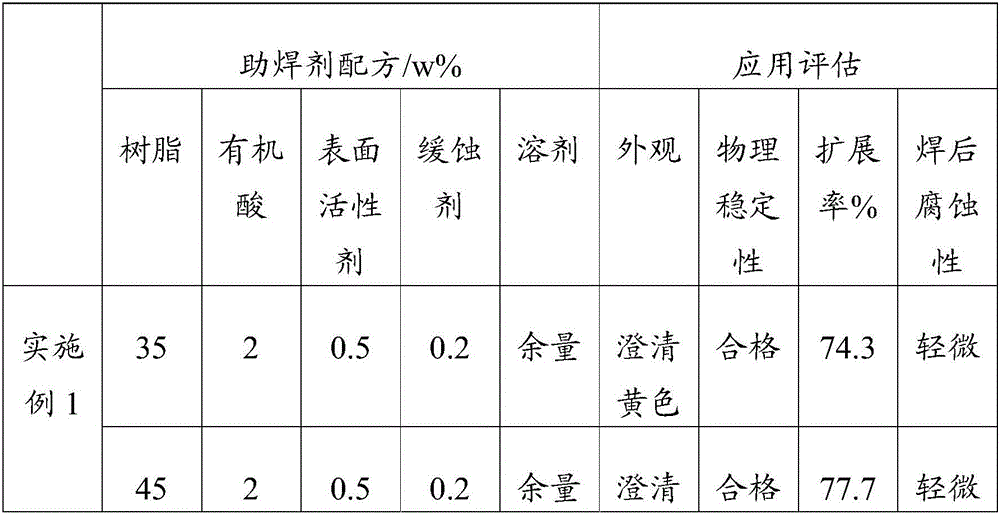

Scaling powder capable of preventing head-in-pillow effect and preparation method and application thereof

ActiveCN106670680ALong soak preheating timeLong reflow soldering conditionsWelding/cutting media/materialsSoldering mediaOrganic acidPolyamide

The invention discloses scaling powder capable of preventing the head-in-pillow effect and a preparation method and application thereof, and belongs to the technical field of solder. The scaling powder capable of preventing the head-in-pillow effect comprises, by weight percentage, 30-50% of unsaturated rosin resin, 20-50% of solvents, 5-20% of thixotropic agents and 1-10% of organic acid. The scaling powder preventing the head-in-pillow effect is prepared through the steps of crushing the unsaturated rosin resin, adding the crushed unsaturated rosin resin into the organic acid, and heating the mixture to 90 DEG C while stirring; adding the solvents into the mixture, naturally cooling the mixture to 80 DEG C after the solvents are dispersed uniformly, adding polyamide into the mixture, and heating the mixture while the polyamide is dispersed until the whole solution becomes transparent; and naturally cooling the mixture to 60 DEG C, then adding hydrogenated castor oil into the mixture, and cooling the mixture to obtain light yellow paste. After the scaling powder is mixed with lead-free tin powder to prepare soldering paste, the requirements of reflow soldering working conditions with long soaking and preheating time and high soaking and preheating temperature can be met, and good effects with good wetting property and bright welding spots and almost without tin sweats can be realized. The scaling powder has excellent performance of preventing the head-in-pillow effect.

Owner:广州适普电子有限公司

Soft water-based washing agent and washing method

ActiveCN109370808AEasy to prepareLow costCationic surface-active compoundsNon-ionic surface-active compoundsCompound aSoft water

The invention provides a soft water-based washing agent and a washing method. The soft water-based washing agent is prepared from the following raw materials in percentage by mass: 6-12% of a surfactant, 0-0.1% of a corrosion inhibitor, 0-0.05% of a defoaming agent, and the balance of deionized water, wherein the surfactant is prepared by compounding a nonionic surfactant, an aqueous anion surfactant, a binary nonionic surfactant and a cationic surface active agent; the nonionic surfactant and the binary nonionic surfactant correspondingly account for 25-35% of the total weight; the aqueous anion surfactant accounts for 10-25% of the total weight; the cationic surfactant accounts for 20-29% of the total weight. With the adoption of the washing agent and the washing method, the surface residues obtained by welding with a rosin flux can be removed; a welding spot can be kept bright, and the surface insulation performance is high; the washing agent is low in complete volatility, and is safe, environmentally friendly, and free from harmful substances; the cost is low; the preparation method is simple; almost no foam is generated in the washing process; the washing technology is eas tooperate.

Owner:CHONGQING UNIV OF TECH

Water based detergent used for high density packing and cleaning method

PendingCN109370796AEasy to prepareLow costNon-ionic surface-active compoundsOrganic detergent compounding agentsWater basedActive agent

The invention provides a water based detergent used for high density packing and a cleaning method. The water based detergent is prepared from the following raw materials by mass percentage: 6%-12% ofa surfactant, 0%-0.1% of a corrosion inhibitor, 0%-0.05% of a defoaming agent and the balance of deionized water, wherein the surfactant is formed by compounding the following ingredients by weight percentage: 50%-69% of a nonionic surfactant, 30%-49% of a waterborne anionic surfactant and 1%-20% of a binary starnonionic surfactant. Through the match of the detergent and a cleaning process, surface residues after welding of a rosin flux can be strongly removed, a welding spot keeps bright, and the insulating property of the surface is high; the detergent is completely halogen-free, is low involatility, is safe and environmentally friendly and does not generate public nuisance substances. The water based detergent is low in cost and simple in preparation method, almost no foam is generated in a cleaning process, and the cleaning process is easily operated.

Owner:CHONGQING UNIV OF TECH

Low-foam high-efficiency water-base detergent and cleaning method

ActiveCN109370809AEasy to prepareLow costCationic surface-active compoundsNon-ionic surface-active compoundsWater basedAlkylphenol

The invention provides a low-foam high-efficiency water-base detergent and a cleaning method. The low-foam high-efficiency water-base detergent is prepared from the following raw materials in percentage by mass: 6-12% of a surfactant, 0-0.1% of a corrosion inhibitor, 0-0.5% of a defoaming agent and the balance of deionized water, wherein a nonionic surfactant is prepared from any one, two, three or four of fatty alcohol-polyoxyethylene ether, Tween-20, alkylphenol polyoxyethylene 9-ether and triethanolamine through mixing in a respective mass ratio greater than 0%; and a cationic surfactant isprepared from any one, two or three of hexadecyl trimethyl ammonium chloride, tetradecyl trimethyl ammonium chloride and dodecyl trimethyl ammonium chloride through mixing in a respective mass ratiogreater than 0%. Together with a cleaning process, the detergent is capable of strongly removing surface residues after welding of a rosin type welding flux, a welding point is kept bright, and good surface insulation is achieved; and the detergent is low in volatilization in the cleaning process, free of pollution substance which can affect health of operators, and in addition free of bubble in the cleaning process.

Owner:CHONGQING UNIV OF TECH

Circuit board cleaning agent and preparation method thereof

InactiveCN104099194AHarm reductionNo pollution in the processNon-surface-active detergent solventsDiethylene glycol monobutyl etherDiacetone alcohol

The invention belongs to the technical field of cleaning agents and relates to a circuit board cleaning agent and a preparation method thereof. The circuit board cleaning agent comprises, by weight, 50-80 parts of cyclohexane, 10-30 parts of diacetone alcohol, 1-5 parts of diethylene glycol monobutyl ether and 5-20 parts of anhydrous ethanol. The circuit board cleaning agent can fast remove oil stain, scolding tin and rosin, can guarantee a good cleaning rate and good cleaning effects, belongs to a low-toxicity and eco-friendly cleaning agent and produces small damage on the human body. The preparation method has simple processes, utilizes easily available raw materials, has simple preparation processes and a low production cost and is conducive to general popularization application.

Owner:广东剑鑫科技股份有限公司

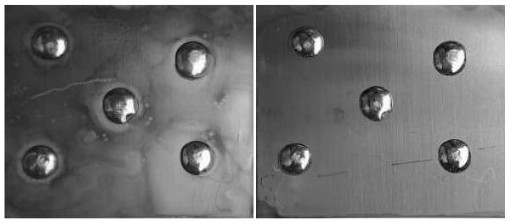

Oxygen-permeation-resistant soldering paste and preparation method thereof

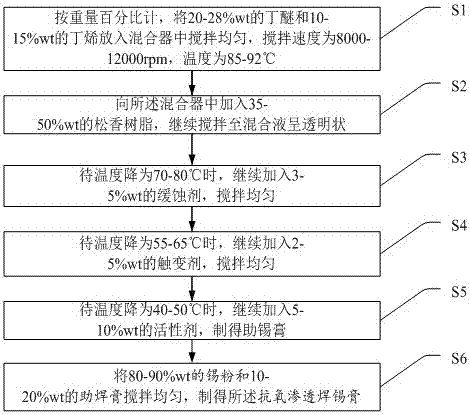

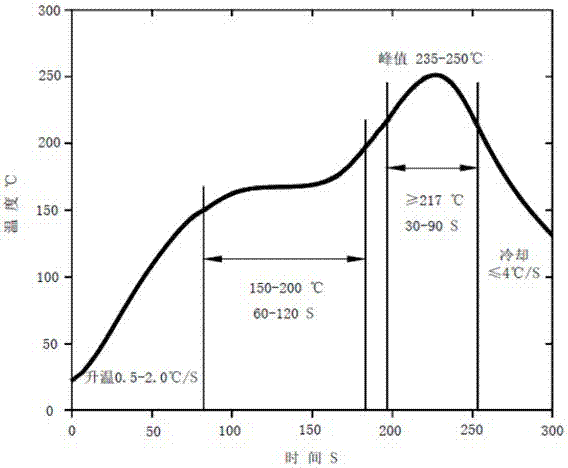

ActiveCN107150186AImprove antioxidant capacityReduce lossWelding/cutting media/materialsSoldering mediaActive agentOxygen

The invention discloses oxygen-permeation-resistant soldering paste and a preparation method thereof. The oxygen-permeation-resistant soldering paste comprises, by weight, 80-90% of tin powder and 10-20% of paste flux, wherein the paste flux comprises, by weight, 20-28% of butyl ether, 10-15% of butene, 3-5% of a corrosion inhibitor, 2-5% of thixotropic agent modified hydrogenated castor oil and 5-10% of an active agent. According to the oxygen-permeation-resistant soldering paste provided by the invention, under the saddle-type reflux temperature curve conditions, the oxidation resistance of the paste flux is obviously improved through formula improvement even though under the long-time high temperature preservation, so that the losses of the active agent are reduced to the minimum, and the good effects of good wetting, bright welding spots and almost inexistence of soldering balls are achieved in the welding process.

Owner:HOERSON ELECTRONICS TECH

Water-based flux with low volatility and low solid content and preparation method thereof

PendingCN109530973ALow solidsLow costWelding/cutting media/materialsSoldering mediaActive agentAlkylphenol

The invention provides a water-based flux with low volatility and low solid content and a preparation method thereof, wherein the components and the mass percents are as follows: 1.5 to 6 percents ofan active agent; 2.5 to 6 percents of a surfactant, 0 to 0.3 percent of a film-forming agent, 0.3 to 0.8 percent of an antioxidant, 0 to 0.8 percent of an additive, 0.01 to 0.5 percent of a corrosioninhibitor and the balance of solvent deionized water. The active agent is mixed by at least two kinds of lactic acid, acrylic acid, DL-malic acid, adipic acid and fumaric acid, and the mass ratio of each of which is greater than 0%, and the temperature is controlled at 30-60 DEG C during mixing. The surfactant is alcohol ether carboxylate, or alkylphenol polyoxyethylene, or acetylenic diol ethoxylates, or is mixed by any two of the above in a mass ratio of greater than 0% each. The film-forming agent is triethanolamine. The antioxidant is hydroquinone. The corrosion inhibitor is hydroxypropylchitosan. The water-based flux is halogen-free, rosin-free, and is low in solid content, and deionized water is used as a solvent, the cost is low, the volatile gas is little, the irritating odor is not present, the tin-frying phenomenon is not present, and the physical health is not affected, and the environment is protected.

Owner:CHONGQING UNIV OF TECH

Low-volatilization high-performance water-base detergent and cleaning method

ActiveCN109370812AEasy to prepareLow costCationic surface-active compoundsOrganic detergent compounding agentsWater basedCleansing Agents

The invention provides a low-volatilization high-performance water-base detergent and a cleaning method. The low-volatilization high-performance water-base detergent is prepared from the following rawmaterials in percentage by mass: 6-12% of a surfactant, 0-0.1% of a corrosion inhibitor, 0-0.5% of a defoaming agent and the balance of deionized water, wherein the surfactant is prepared from a nonionic surfactant, a zwitterionic surfactant, a binary star nonionic surfactant and a cationic surfactant through compounding; the nonionic surfactant and the binary star nonionic surfactant account for50-69% of the total weight of the surfactant; the zwitterionic surfactant accounts for 10-25% of the total weight of the surfactant; and the cationic surfactant accounts for 15-35% of the total weight of the surfactant. Together with a cleaning process, the detergent is capable of strongly removing surface residues after welding of a rosin type welding flux, a welding point is kept bright, and good surface insulation is achieved; and compared with a conventional detergent, the detergent is completely low in volatilization, safe and environmental-friendly, free of pollution substance, free ofbubble in the cleaning process, and easy in cleaning process operation.

Owner:广州启岩新材料科技有限公司

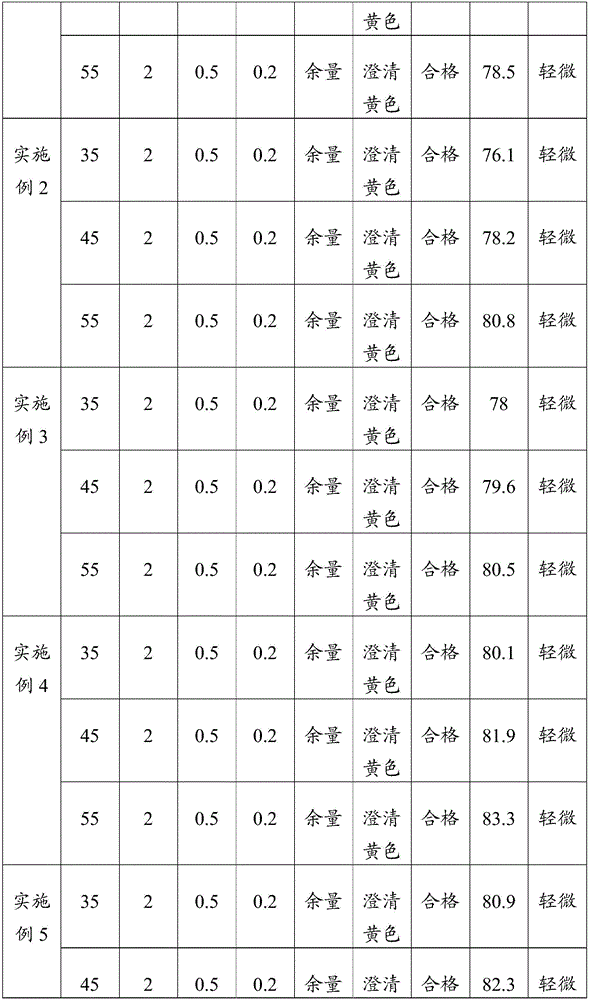

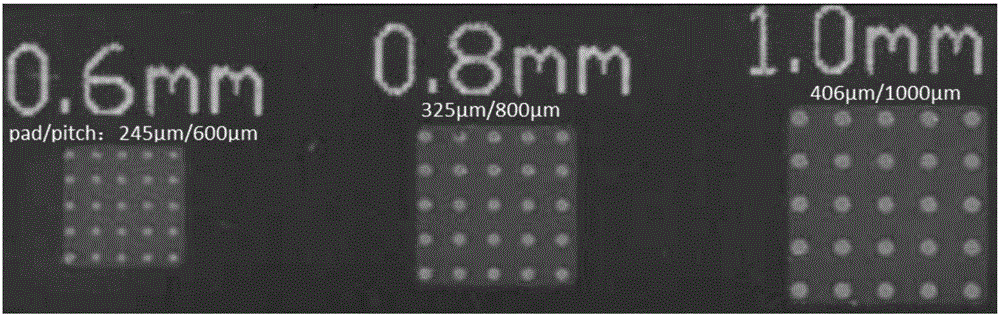

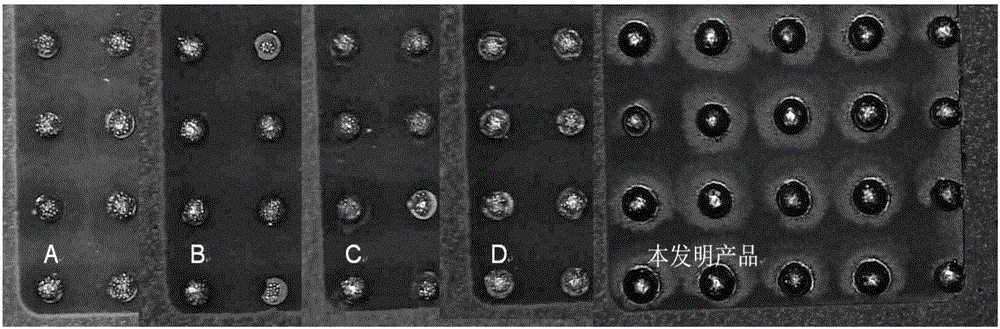

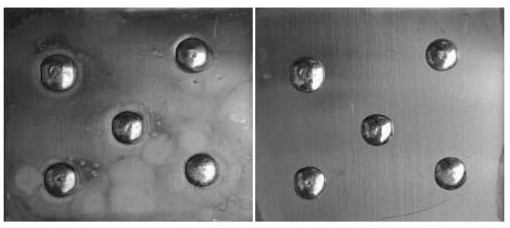

Solder paste for improving BGA package welding performance and preparation method thereof

ActiveCN111571065AIncrease energy densityHigh speedWelding/cutting media/materialsSoldering mediaActive agentSolder ball

The invention provides a solder paste for improving the BGA package welding performance. The solder paste is prepared from tin powder and paste flux, wherein the mass ratio of the tin powder to the paste flux is 89:11, the paste flux is prepared from the following components in parts by weight: 35 to 40 parts of rosin, 40 to 45 parts of solvents, 5 to 10 parts of thixotropic agents, 5 to 10 partsof active agents, 1 to 2 parts of antioxidants, 1 to 2 parts of polyazide modifiers and 0.5 to 1 part of fluorocarbon surfactant. The invention further provides a preparation method of the solder paste. According to the solder paste provided by the invention, the bad welding performance caused by the temperature in a cover plate can be effectively avoided, and good welding effects of wetness, brightness of welding spots and no solder ball are achieved.

Owner:深圳市唯特偶新材料股份有限公司 +1

Electronic assembling water-based detergent and cleaning method

PendingCN109370811AEasy to prepareLow costCationic surface-active compoundsOrganic detergent compounding agentsWater basedCleaning methods

The invention provides an electronic assembling water-based detergent and a cleaning method. The electronic assembling water-based detergent is prepared from the following raw materials in percentageby mass: 6-12% of a surfactant, 0-0.1% of a corrosion inhibitor, 0-0.5% of a defoaming agent and the balance of deionized water, wherein the surfactant is prepared from a nonionic surfactant, a zwitterionic surfactant and a binary star nonionic surfactant through compounding; the nonionic surfactant accounts for 50-69% of the total weight of the surfactant; the zwitterionic surfactant accounts for20-49% of the total weight of the surfactant; and the binary star nonionic surfactant accounts for 1-30% of the total weight of the surfactant. Together with a cleaning process, the detergent is capable of strongly removing surface residues after welding of a rosin type welding flux, a welding point is kept bright, and good surface insulation is achieved; and the detergent is completely free of halogen, low in volatilization, safe and environmental-friendly, free of pollution substance, low in cost, simple in preparation method, free of bubble in the cleaning process, applicable to full-automatic cleaning and ultrasonic cleaning, and easy in cleaning process operation.

Owner:CHONGQING UNIV OF TECH

Water-based cleaning agent with strong dispersing capacity, and cleaning method thereof

ActiveCN111040888AQuick wetQuickly wets and penetratesInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsLipid formationChlorobenzene

The invention provides a water-based cleaning agent with strong dispersing capacity, and a cleaning method thereof, wherein the cleaning agent comprises narrow-distribution fatty alcohol-polyoxyethylene ether and a nonionic surfactant. According to the invention, the cleaning agent prepared by the preparation method has strong cleaning capability on granular pollutants wrapped by rosin or other lipid compounds, can effectively remove pollutants in difficult-to-clean positions such as deep holes, blind holes and the like, and is simple and stable in components, free of layering, not prone to volatilization and decomposition, free of corrosion effect on welding spots, is wide, inexpensive and easily-available in raw materials, low in cost, low in waste liquid treatment cost, free of toxic substances such as sulfur, chlorine, benzene, heavy metals and the like, and low in harm to human bodies and the environment; the cleaning process is easy to operate, free of residues, high in cleanliness and bright in welding spot; and the application field is wide, and the application prospect is good.

Owner:CHONGQING UNIV OF TECH

Low-carbon low-volatility water-based flux and preparation method thereof

PendingCN109530971ASolder joints are fullRound solder jointsWelding/cutting media/materialsSoldering mediaBenzoic acidWater based

The invention provides a low-carbon low-volatility water-based flux and a preparation method thereof. The low-carbon low-volatility water-based flux is prepared from the following components, by mass:2-4.5% of an active agent, 1.5-4% of a surface active agent, 0-0.4% of a film-forming agent, 0.01-0.3% of an antioxidant, 0.01-0.4% of a corrosion inhibitor and the balance a solvent, specifically, the active agent is prepared by mixing at least two of succinic acid, benzoic acid, DL-malic acid and adipic acid at the mass ratio of greater than 0% respectively at the temperature of 30-60 DEG C; and the surface active agent is any one of AEC-9NA or TX-10 phosphate, or the surface active agent is prepared by mixing both of the AEC-9NA and TX-10 phosphate at the mass ratio of greater than 0% respectively. The flux has low solid residue content, no halogen, no rosin, low carbon, no volatile organic compound, no irritating odor, little corrosion to a circuit board, and round and bright solder joints. Besides, the flux is easy to manufacture, quite low in cost, convenient to store and transport, free of solder explosion, stable in chemical property, free of influence on physical health of operators and environmentally friendly.

Owner:CHONGQING UNIV OF TECH

Cleaning-free multifunctional solvent-type soldering flux

InactiveCN110449773ALess corrosiveNo pungent odorWelding/cutting media/materialsSoldering mediaFoaming agentActive agent

The invention discloses a cleaning-free multifunctional solvent-type soldering flux. The soldering flux comprises the following components of, in percentage by mass, 1.5% - 6.5% of an active agent, 0%- 0.2% of a surfactant, 0.05% - 1.5% of an antioxidant, 0.05% - 0.5% of a corrosion inhibitor, 0.1% -1.5% of an additive, 0% -2% of a foaming agent and the balance a solvent, wherein the total mass of the whole component is 100%. The cleaning-free multifunctional solvent-type soldering flux is free of halide and non-toxic, pungent smell is not generated, harm is not caused to a human body and a natural environment, and the corrosion to a circuit board is greatly reduced; and the soldering flux has the advantages of being high in activity, obvious in soldering-aid effect, good in wettability,smooth and full and free of shrinkage and tin blasting phenomena in soldering spot, suitable for high-integration packaging and free of introducing other auxiliary equipment; the surface of the circuit board is extremely low in residue, soldering spots are attractive and bright, a cleaning process does not need to be introduced; and the universality is good, and the soldering flux is suitable forSn - Ag, Sn - Cu systems or low silver lead-free brazing filler metal alloys.

Owner:CHONGQING UNIV OF TECH

Lead free tin cream and preparation process

InactiveCN1264640CImprove surface activityIncrease stickinessWelding/cutting media/materialsSoldering mediaOrganic acidVegetable oil

The invention provides a lead-free solder paste comprising the tin base alloy welding powder and the pewter. The components of the tin base alloy welding powder are as follows (in % by weight): Sn 91-99, Cu 0.5-3, Ag 0.5-6; the components of the pewter are as follows (in % by weight): mixed alcohol ether 25-40, natural colophony 50-70, natural vegetable oil thixotropic agent 5-15, organic acid 0.5-2.0, additives. The lead-free solder paste preparing process includes the following steps: mixing the components of the pewter in proportion, standing to room temperature, putting the pewter in a refrigerating chamber with the temperature of 1 C. to 10 C. for 48 hours; mixing the pewter and the tin base alloy welding powder in the ratio of 1 to 9 in the vacuum dispersion machine, putting the mixture in the package bottle and storing hermetically with the temperature of between 5 C. and 10 C.. The lead-free solder paste is characterized by good surface activity, moderated viscosity, and no smell.

Owner:倪潮春

Halogen-free lead-free tin wire

InactiveCN102248317BImprove reliabilitySolder joints are fullWelding/cutting media/materialsSoldering mediaHalogenOrganic solvent

The invention relates to the technical field of tin wires, in particular to a composite halogen-free lead-free tin wire in line with the EU (European Union) directive. The tin wires comprise the following components in parts by per unit mass: 96-98 parts of tin, 0.6-0.7 part of copper, 0.1-0.2 part of resin, 0.1-0.2 part of non-fluorochloro environmentally-friendly organic solvent, 0.05-0.06 part of thixotropic agnet, 0.02-0.4 part of organic active agent, 0.01-0.02 part of corrosion inhibitor, and 0.01-0.02 part of surfactant, wherein the tin and the copper are the solder of the tin wire, and others are soldering flux. By using said technical scheme in the invention, the product is in line with relative directive of the EU and free from lead and relative halogen. Furthermore, the reliability of the welding is high, bad welding spot cannot be formed, and the welding spot is full and bright.

Owner:JIANGXI UNIV OF SCI & TECH +1

Green environment-friendly neutral water-based cleaning agent and its preparation method and application

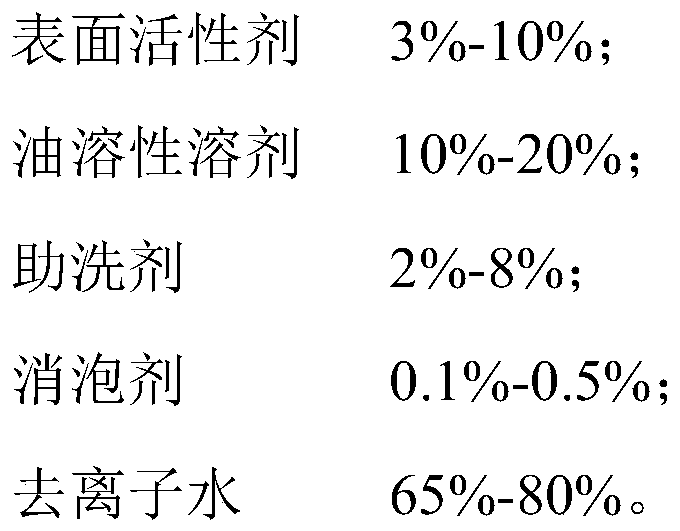

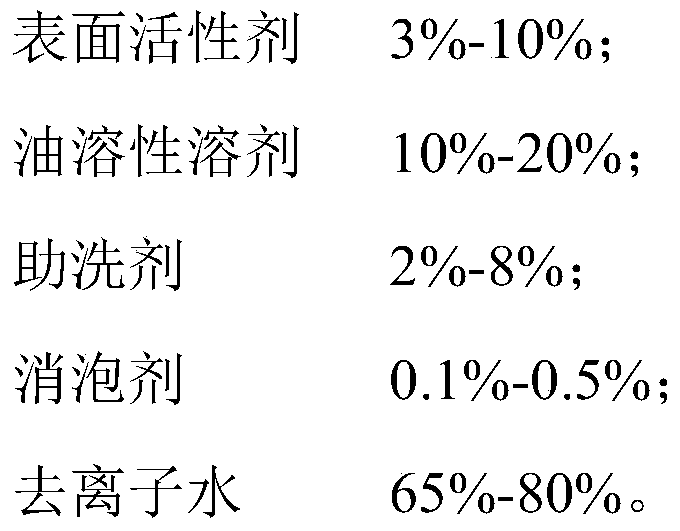

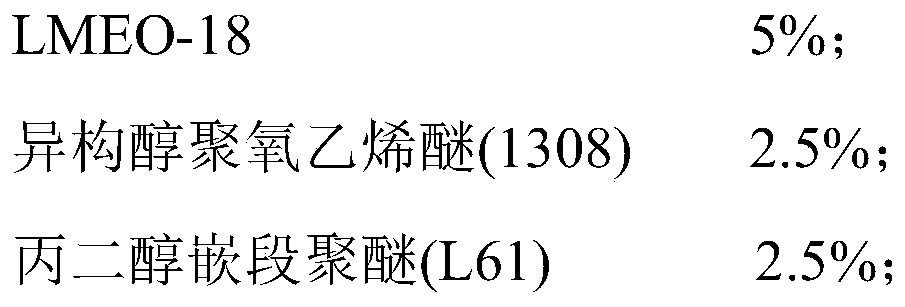

ActiveCN105331471BMild performanceLight performanceSurface-active non-soap compounds and soap mixture detergentsActive agentSurface-active agents

The invention relates to the technical field of cleaning agents, and specifically discloses a green and environment-friendly neutral water-based cleaning agent as well as its preparation method and application. The cleaning agent includes the following components in mass percentage: surfactant 3%-10%; oil-soluble solvent 10%-20%; builder 2%-8%; defoamer 0.1%-0.5%; deionized water 65%‑80%. The raw materials of the present invention are all neutral products with mild performance, and the cleaning agent produced has light smell, no halogen, no flash point, no corrosion of materials, no phosphorus and environmental protection, no influence on the cleaned components, and good material compatibility , non-flammable, non-explosive, safe to use, strong cleaning power, and the solder joints of parts after cleaning remain bright, etc., suitable for PCB cleaning.

Owner:SHENZHEN UNIBRIGHT TECH

A kind of complex environment water-based cleaning agent and cleaning method

ActiveCN111040893BImprove compatibilityEfficient removalInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater useActive agent

The invention discloses a complex environment water-based cleaning agent, which is characterized in that it is made of the following raw materials in weight percentage: surfactant: 3%-12%; corrosion inhibitor: 0.01%-0.25%; defoamer: 0.1%~0.3%; the balance is deionized water, and the sum of the weight percentages of each component is 100%. The water-based cleaning agent obtained by the present invention can quickly and effectively remove flux residues and other pollutants on the surface of components, and has good compatibility and wide application range, especially suitable for complex environments such as high temperature, high acid, alkali and high oxidation In the cleaning process; low foam, low volatility, low toxicity, good cleaning effect, no residue on the surface after washing, and bright solder joints; the water-based cleaning agent is simple to prepare, and the cleaning process is easy to operate. It is used in conjunction with automatic spray cleaning and ultrasonic cleaning on the market.

Owner:CHONGQING UNIV OF TECH

Halogen-free high-activity cleaning-free solvent type soldering flux

InactiveCN110449772ALess corrosiveNo pungent odorWelding/cutting media/materialsSoldering mediaFoaming agentActive agent

The invention discloses a halogen-free high-activity cleaning-free solvent type soldering flux. The halogen-free high-activity cleaning-free solvent type soldering flux comprises the following components of, in percentage by mass, 1.8%-5.8% of an active agent, 0%-0.15% of surfactant, 0.08%-1.5% of an antioxidant, 0.05%-0.5% of a corrosion inhibitor, 0.08%-1.5% of an additive, 0%-1.5% of a foamingagent, and the balance a solvent, and the total mass of the whole components is 100%. The halogen-free high-activity cleaning-free solvent type soldering flux has the advantages of no halide, no toxicity, no pungent smell and no harm to the human body and the natural environment, and greatly reduces the corrosion to a circuit board; the activity is high, the soldering assisting effect is obvious,the wettability is good, welding spots are full and free of retraction and tin explosion, the high-integration packaging is met, and other auxiliary equipment does not need to be used; the surface ofthe circuit board is extremely low in residue, and the welding spots are attractive and bright; and the soldering flux has good universality for Sn-Ag, Sn-Cu series or low silver lead-free solder alloys.

Owner:CHONGQING UNIV OF TECH

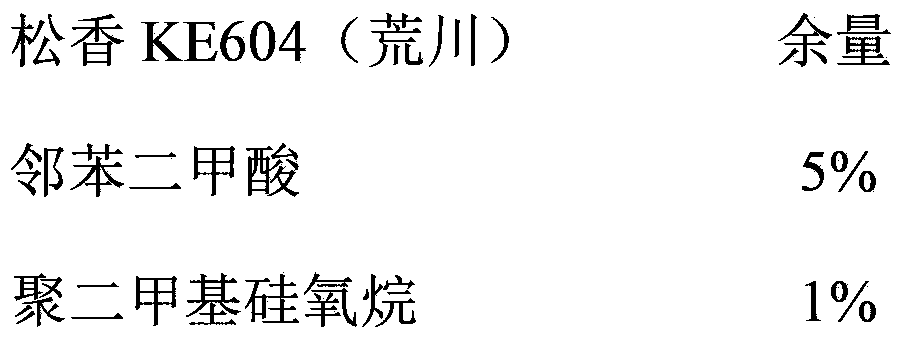

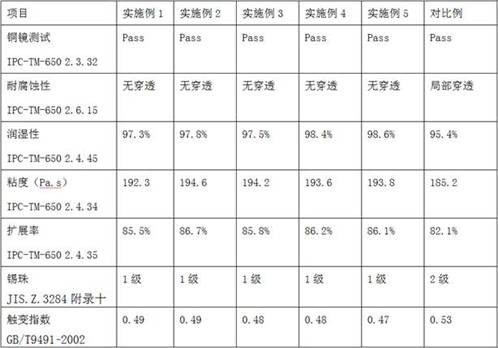

SMT soldering paste with high wetting dispersibility and weather resistance and preparation method of SMT soldering paste

PendingCN114101972ANo oxidationBright spotWelding/cutting media/materialsSoldering mediaWeather resistanceActive agent

The invention provides SMT (surface mount technology) soldering paste with high wetting dispersity and weather resistance, which is prepared from the following components in percentage by mass: 70 to 80 percent of micron-sized tin-silver-copper alloy powder, 0.5 to 5 percent of antioxidant, 4.4 to 18 percent of resin, 3.2 to 7 percent of active agent, 0.5 to 0.9 percent of thixotropic agent, 3 to 5 percent of solvent, 0.1 to 1 percent of wetting agent, 0.1 to 1 percent of corrosion inhibitor and 0.1 to 1 percent of dispersing agent. Compared with commercially available solder paste, the solder paste has the advantages of high wettability, corrosion resistance and expansion rate, good thixotropy, capability of effectively reducing the generation of tin beads, less surface residue and no need of pre-dispersion by a centrifugal machine before use, not only meets related detection standards, but also can be directly used after temperature return.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

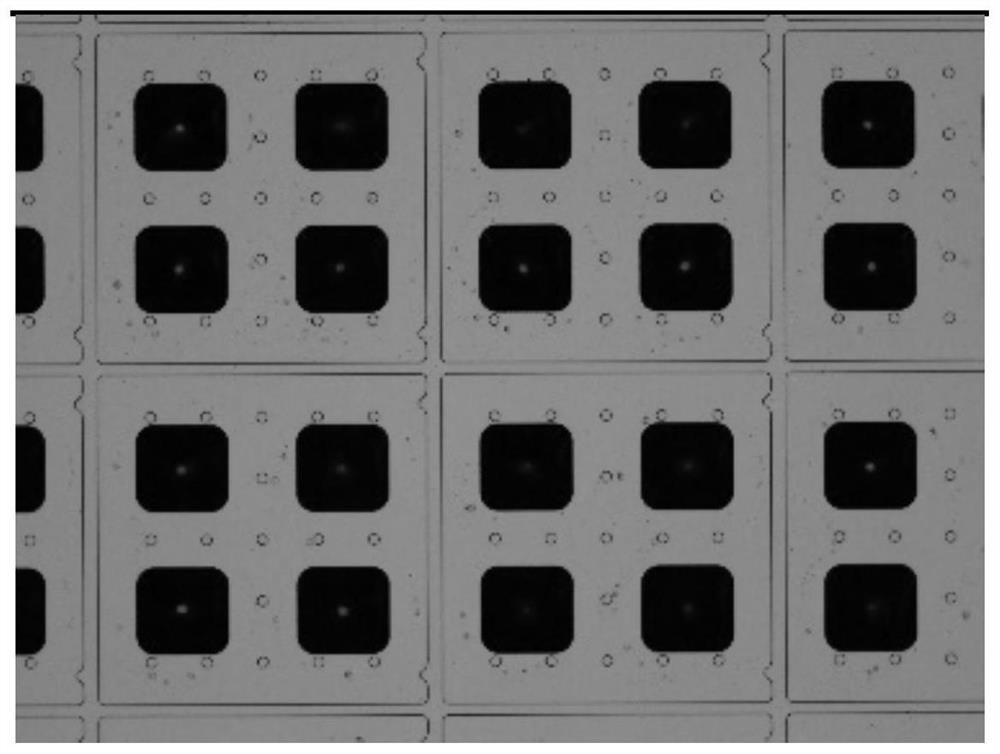

A kind of solder paste for improving BGA package soldering performance and preparation method thereof

ActiveCN111571065BIncrease energy densityHigh speedWelding/cutting media/materialsSoldering mediaActive agentSurface-active agents

The invention provides a solder paste for improving the soldering performance of BGA packaging, which is made of tin powder and solder paste with a mass ratio of 89:11; wherein, the solder paste is composed of the following components by weight: Rosin 35 ~40 parts, 40~45 parts of solvent, 5~10 parts of thixotropic agent, 5~10 parts of active agent, 1~2 parts of antioxidant, 1~2 parts of polyazide modifier, 0.5 parts of fluorocarbon surfactant ~ 1 serving. The invention also provides a preparation method of the solder paste. The solder paste provided by the invention can effectively avoid the poor soldering performance caused by the temperature inside the cover plate, and obtain good soldering effects of moistness, bright solder joints and no tin beads.

Owner:深圳市唯特偶新材料股份有限公司 +1

Soldering flux in use for SnZn series solder with no lead, and preparation method

InactiveCN100455400CImprove wettabilityGood formabilityWelding/cutting media/materialsSoldering mediaAlcoholSolvent

Owner:DALIAN UNIV OF TECH

Water-based flux cleaning agent as well as preparation method and application thereof

ActiveCN114106935AAchieve removalAvoid it happening againOrganic detergent compounding agentsAnionic surface-active compoundsActive agentGlycol ethers

The invention provides a water-based flux cleaning agent as well as a preparation method and application thereof. The water-based flux cleaning agent comprises the following components in parts by weight: 5-30 parts of alcohol amine; 10-55 parts of a glycol ether compound; 1-25 parts of a polar solvent; 0.001 to 10 parts of a chelating type surfactant; 0.1 to 5 parts of a pH regulator; 0.1 to 10 parts of amino acid; 0.001 to 10 parts of a wetting agent; and 5-60 parts of deionized water. The invention further discloses a preparation method and application of the water-based flux cleaning agent. The water-based flux cleaning agent is low in use concentration and harmless to human bodies and the environment. The water-based flux cleaning agent disclosed by the invention has excellent flux cleaning capability, and can inhibit oxidation and corrosion of a chip substrate, so that the yield of chips is effectively improved.

Owner:ZHEJIANG AUFIRST MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com