Oxygen-permeation-resistant soldering paste and preparation method thereof

A solder paste, oxygen penetration technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of welding defects, oxidation inactivation of active components, etc., and achieve bright solder joints, good wetting, and improved oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present invention provides an anti-oxidation permeation solder paste, which includes the following components by weight percentage: metal tin powder 80-90%wt, solder paste 10-20%wt, wherein the solder paste is measured by the following weight percentage Components: butyl ether 20-28%wt, butene 10-15%wt, corrosion inhibitor imidazole and benzotriazole 3-5%wt, thixotropic agent modified hydrogenated castor oil 2-5%wt, add active Agent 5-10%wt, described active agent comprises the polyethylene glycol of 60-80%wt, the malonic acid of 4-10%wt and the dibromobutene glycol of 16-30%wt, as the present invention preferred implementation.

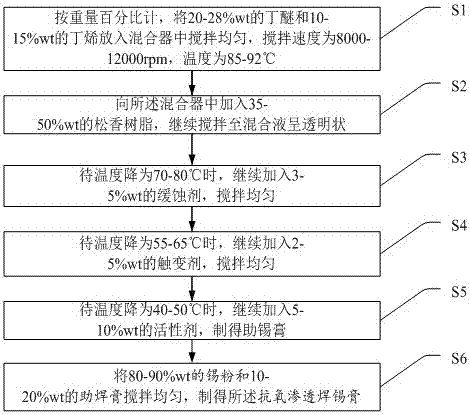

[0038] The preparation method of above-mentioned anti-oxidation penetration solder paste comprises the following steps:

[0039] A. Put 20-28%wt of butyl ether and 10-15%wt of butene into the mixer for stirring and dispersing. The dispersing rate is 10000rpm / min, and the dispersing temperature is 90℃. Mix and disperse until it becomes tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com