A kind of complex environment water-based cleaning agent and cleaning method

A water-based cleaning agent, technology for complex environments, applied in detergent compounding agents, detergent compositions, chemical instruments and methods, etc. Wide application range, remarkable cleaning effect, low volatility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method of a complex environment water-based cleaning agent, comprising the following steps:

[0042] Measure the raw materials of each component according to the composition and content ratio of the water-based cleaning agent in the aforementioned complex environment, add deionized water into the reaction kettle with a stirrer and start stirring, heat the reaction kettle, and keep the temperature at 30 At ±5°C, add surfactant, corrosion inhibitor and defoamer respectively, keep stirring until completely mixed, then stop stirring.

[0043] A method for cleaning complex environments with water-based cleaning agents, comprising the steps of:

[0044] 1) Use a water bath to heat the liquid medicine in a closed container to 25°C~40°C;

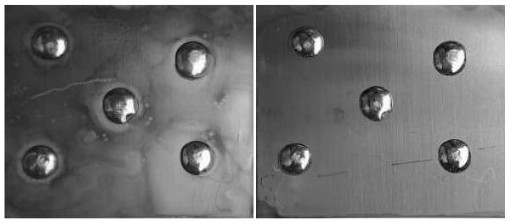

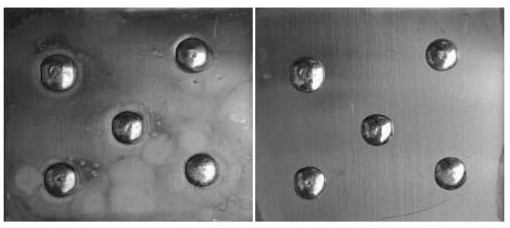

[0045] 2) Soak the pieces to be washed in the liquid medicine in step 1) for 20min~35min, and then put the pieces to be washed into the ultrasonic cleaning machine after soaking. The cleaning time is 10min~25min, and the cleani...

Embodiment 1

[0049] The composition of the water-based cleaning agent for complex environments is as follows: Surfactant accounts for 5% by weight, of which non-ionic surfactant:anionic surfactant=3:7, corrosion inhibitor 0.01%, defoamer 0.1%, and the balance for deionized water.

Embodiment 2

[0051] The composition of the water-based cleaning agent for complex environments is as follows: Surfactant accounts for 6% by weight, of which nonionic surfactant:anionic surfactant=7:15, corrosion inhibitor 0.05%, defoamer 0.12%, and the balance for deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com