A special solder paste for aluminum welding and its preparation method and use method

A solder paste, aluminum technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the problems of weak solder joints, poor diffusion, affecting welding firmness, etc., to enhance the firmness of solder joints , excellent fatigue characteristics, beneficial to anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

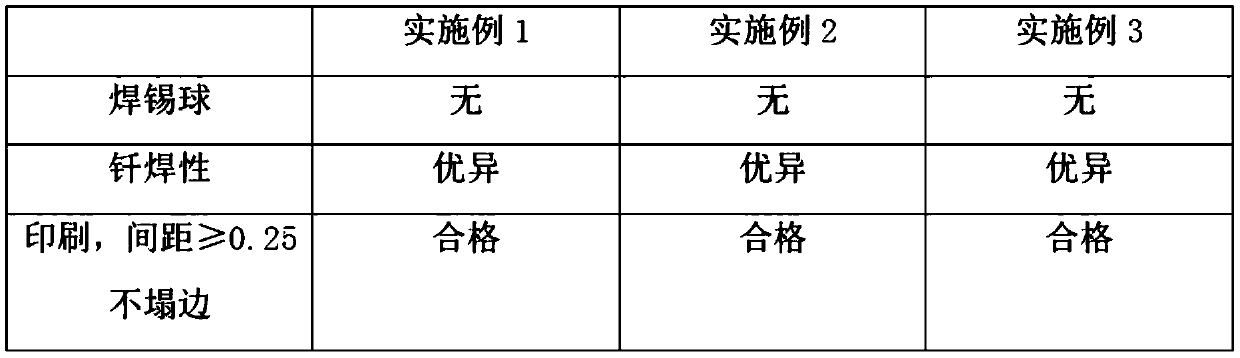

Examples

Embodiment 1

[0031] The invention provides a special solder paste for welding aluminum materials. The solder paste is composed of the following components in weight percent: 84% solder powder, 11% flux, 3% 2-octyldodecanol, tallow diamine diol Salt 2%;

[0032] The solder powder is composed of the following components by weight percentage: Zn 3.2%, Bi 1.6%, In 0.7%, Ga0.4%, Sb 0.2%, Ru 0.1%, and the balance is Sn;

[0033] The flux is composed of the following components in weight percentage: 40% maleic rosin, 20% diethylene glycol butyl ether acetate, 10% 2-methyl-2,4-pentanediol, 10% malonic acid , behenic acid 5%, lithium magnesium silicate 8%, coco monoethanolamide polyoxyethylene ether 2%, cetearyl glucoside 2%, o-tert-butyl hydroquinone 2%, butyl Hydroxyanisole 1%.

[0034] A preparation method of special solder paste for aluminum welding, comprising the following steps;

[0035] (1) Weigh the raw material components of the flux according to the formula ratio, mix malea rosin, die...

Embodiment 2

[0043] A special solder paste for aluminum material welding, the solder paste is composed of the following components in weight percentage: 86% of solder powder, 10% of flux, 2% of 2-amino-2-methyl-1-propanol, polypropylene Acyldimethylammonium taurate 2%;

[0044] The solder powder is composed of the following components by weight percentage: Zn 4.0%, Bi 2.0%, In 1.0%, Ga0.6%, Sb 0.3%, Ru 0.2%, and the balance is Sn;

[0045]The flux is composed of the following components in weight percent: 25% maleic rosin pentaerythritol ester, 20% maleic rosin glyceride, 18% 2-ethyl-1,3-hexanediol, 14% dipropylene glycol dimethyl ether %, 7% tartaric acid, 6% phthalic acid, 3% organic bentonite, 2% hydrogenated castor oil, 2% methyl glucose polyoxyethylene ether, 1% isostearamidopropyl morpholine lactate, Tributylcatechol 2%.

[0046] A preparation method of special solder paste for aluminum welding, comprising the following steps;

[0047] (1) Weigh the flux raw material components ac...

Embodiment 3

[0055] A special solder paste for aluminum welding, the solder paste is composed of the following components by weight percentage: 89% solder powder, 8% solder flux, 3% cocoyl glutamic acid triethanolamine salt;

[0056] The solder powder is composed of the following components by weight percentage: Zn 4.8%, Bi 2.4%, In 1.3%, Ga0.8%, Sb 0.5%, Ru 0.3%, and the balance is Sn;

[0057] The soldering flux is composed of the following components in weight percent: maleated rosin 20%, maleated rosin pentaerythritol ester 20%, maleated rosin glyceride 10%, diethylene glycol butyl ether acetate 10%, ethylene glycol mono Butyl ether 10%, 2-ethyl-1,3-hexanediol 10%, oxalic acid 5%, fumaric acid 3%, itaconic acid 2%, fumed silica 2.5%, polyamide wax 2.5%, coconut Oil-based monoethanolamide polyoxyethylene ether 2%, hydrogenated castor oil polyoxypropylene ester 2%, ethoxyquinoline 1%.

[0058] A preparation method of special solder paste for aluminum welding, comprising the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com