SMT soldering paste with high wetting dispersibility and weather resistance and preparation method of SMT soldering paste

A technology of wetting, dispersing and weather resistance, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of low viscosity of solder paste, insufficient tin on solder joints, blurred images, etc., and achieve wettability and cutting performance. Good, improve initial viscosity, increase the effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

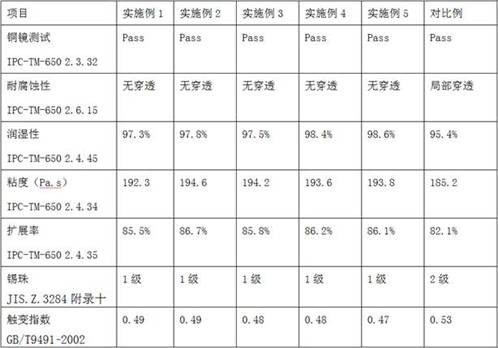

Examples

Embodiment 1

[0031] A SMT solder paste with high wettability, dispersibility and weather resistance, prepared from the following components according to mass percentage:

[0032] Micron (D50:20-38um) Sn96.5-Ag3.0-Cu0.5 alloy powder 70%;

[0033] Antioxidant: Resveratrol 5%;

[0034] Resin: hydrogenated rosin methyl ether 9%, polymerized rosin 9%;

[0035] Active Ingredients: D-Camphoric Acid 3.2%;

[0036] Thixotropic agent: ethylene bis (16-hydroxy) stearic acid amide 0.5%;

[0037] Solvents: Diethylene glycol monocaprylyl ether 1.5%, Dioctyl adipate 1.5%;

[0038] Wetting agent: Oleamidopropyldimethylamine 0.1%;

[0039] Corrosion inhibitor: sulfonated lignin 0.1%;

[0040] Dispersant: Unsaturated polyamine amide 0.1%.

[0041] Adopt the preparation method of a kind of high wetting dispersibility and weather resistance SMT solder paste of above-mentioned component, concrete steps are as follows:

[0042] Step (1) Add the resin (hydrogenated rosin methyl ether, polymerized rosin) i...

Embodiment 2

[0047] A SMT solder paste with high wettability, dispersibility and weather resistance, prepared from the following components according to mass percentage:

[0048] Micron (D50:20-38um) Sn96.5-3.0Ag-Cu0.5 alloy powder 80%;

[0049] Antioxidant: Vitamin E 0.5%;

[0050] Resin: polymerized rosin 2.2%, ice white rosin 2.2%;

[0051] Actives: Azelaic Acid 7%;

[0052] Thixotropic agent: Ethylene bislauric acid amide 0.6%;

[0053] Solvents: Dioctyl Adipate 2.5%, 2-Hexyl-1-Decanol 2.5%;

[0054] Wetting agent: Trimethylbutenediol 0.5%;

[0055] Corrosion inhibitor: cetylamine 1%;

[0056] Dispersant: Polycarboxylate 1%.

[0057] Adopt the preparation method of a kind of high wetting dispersibility and weather resistance SMT solder paste of above-mentioned component, concrete steps are as follows:

[0058] Step (1) Add the resin (polymerized rosin, ice-white rosin) into the solvent (2-hexyl-1-decanol), heat to 80°C, and stir at 400rpm until all are dissolved evenly to obtain...

Embodiment 3

[0063] A SMT solder paste with high wettability, dispersibility and weather resistance, prepared from the following components according to mass percentage:

[0064] Micron (D50:20-38um) Sn96.5-3.0Ag-Cu0.5 alloy powder 75%;

[0065] Antioxidant: Ascorbic Acid 2.5%;

[0066] Resin: Ice White Rosin 5.5%, Hydrogenated Rosin Methyl Ester 5.5%;

[0067] Active Agent: Dipropionic Acid 5%;

[0068] Thixotropic agent: castor oil derivative 0.7%;

[0069] Solvents: 2-Hexyl-1-Decanol 2%, Tetraglyme 2.5%;

[0070] Wetting agent: oleyl alcohol polyoxyethylene ether 0.3%;

[0071] Corrosion inhibitor: octadecylamine 0.5%;

[0072] Dispersant: Polyetheramide 0.5%.

[0073] Adopt the preparation method of a kind of high wetting dispersibility and weather resistance SMT solder paste of above-mentioned component, concrete steps are as follows:

[0074] Step (1) Add the resin (ice-white rosin, hydrogenated rosin methyl ester) into the solvent (2-hexyl-1-decanol), heat to 80°C, stir at 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com