A kind of smokeless solder wire and preparation method thereof

A technology of solder wire and tin solder, applied in the direction of welding equipment, manufacturing tools, welding media, etc., can solve the problems of increasing the physical injury of soldering workers, generating smoke, affecting the environment, etc., to avoid empty soldering and bridging, and improve lubrication Humidity, excellent alkali resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

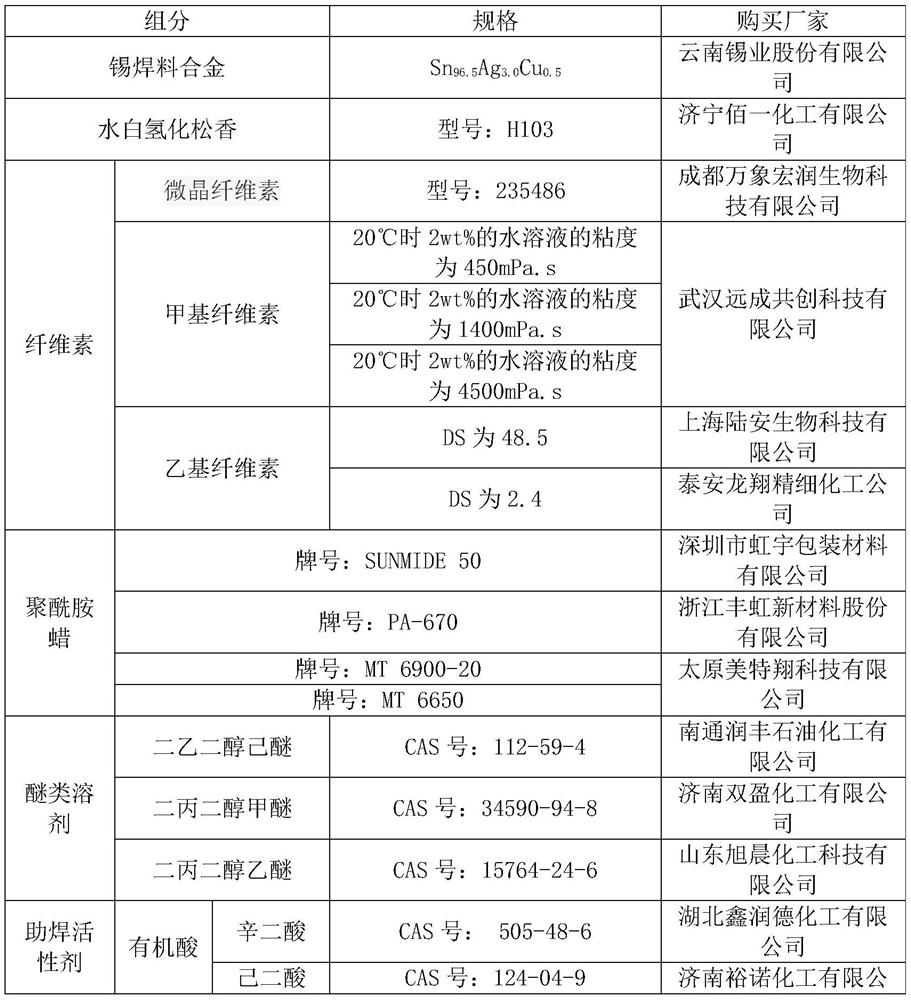

[0037]Preparation examples 1-23 provide a smokeless carrier, and preparation example 1 is taken as an example for illustration below.

[0038] A smokeless carrier provided in Preparation Example 1, the preparation steps are: heating 10g of diethylene glycol hexyl ether (CAS No.: 112-59-4) to 65°C and keeping it warm for 1h, then adding 20g of polyamide wax, stirring Evenly, finally add 40g of microcrystalline cellulose (model: 235486), stir until completely dissolved, and obtain a smokeless carrier;

[0039] Wherein, the polyamide wax is formed by mixing the polyamide wax with the grade of SUNMIDE 50 and the polyamide wax with the grade of MT 6900-20 in a mass ratio of 1:1.2.

preparation example 2-3

[0040] Preparation Examples 2-3 are the same as Preparation Example 1, except that the quality of the raw materials for the preparation of the smokeless carrier is different, see Table 2 for details.

[0041] Table 2

[0042] components Preparation Example 1 Preparation example 2 Preparation example 3 Diethylene glycol hexyl ether (g) 10 15 12.5 Microcrystalline Cellulose (g) 40 60 50 Polyamide wax (g) 20 30 25

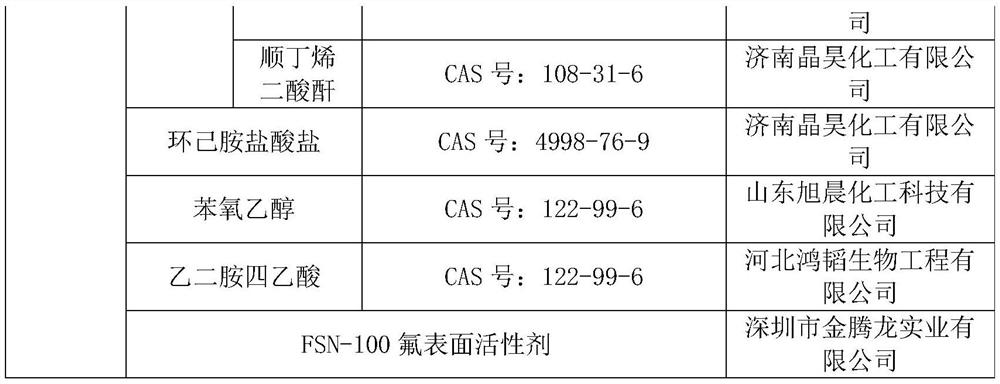

[0043] Preparation Examples 4-5 are the same as Preparation Example 3, except that the composition of the polyamide wax is different, see Table 3 for details.

[0044] table 3

[0045]

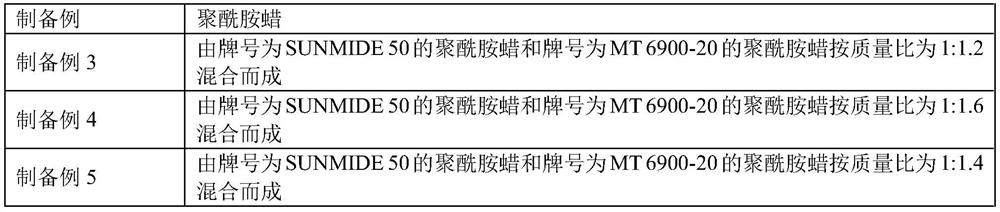

[0046] Preparation Examples 6-11 are the same as Preparation Example 5, except that the type and composition of the cellulose are different, see Table 4 for details.

[0047] Table 4

[0048]

[0049] Preparation Examples 12-17 are the same as Preparation Example 10, except that the types and compositions of the ether solvents are di...

preparation example 18

[0052] Preparation Example 18 is the same as Preparation Example 1, except that the polyamide wax with the brand name of SUNMIDE 50 is replaced with polyamide wax with the brand name of PA-670.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com