Ultrasonic welding base structure

A technology of ultrasonic welding and bottom table, applied in welding equipment, non-electric welding equipment, metal processing equipment and other directions, can solve the problems of increasing manufacturing cost, improve the speed of mold change, improve welding quality, regular and beautiful solder joints. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

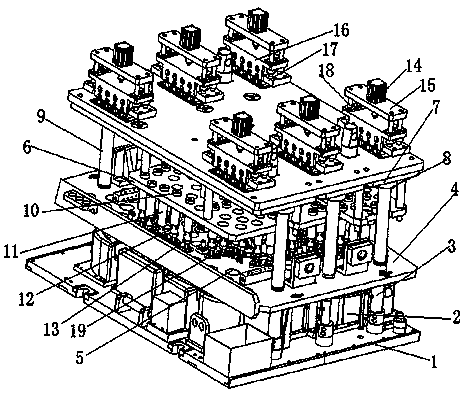

[0012] Example 1, such as figure 1 As shown, an ultrasonic welding bottom platform structure, the ultrasonic welding bottom platform structure includes a bottom plate 1, a bottom support block group 2 arranged on the bottom plate 1, and a synchronous connecting rod arranged at the four corners on the top of the bottom connecting plate Group 3, through the membrane plate structure connected to the synchronous connecting rod group and the upper guide plate structure arranged on the upper part of the membrane plate structure and connected with the synchronous connecting rod group 3, the membrane plate structure includes the membrane connecting plate 4. The guide hole 5 provided on the membrane connection plate, the upper guide plate structure includes an upper guide plate body 6 and multiple sets of upper locking block structures arranged on the upper guide plate body.

[0013] It is characterized in that: the lower part of the upper guide plate structure is movably provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com