A method of using a welding protection device for an air-conditioning liquid reservoir

A protection device and liquid storage technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of reliable welding, poor quality of weld seam, surface oxidation of welding parts, etc., so as to facilitate welding operation and avoid Pollution, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

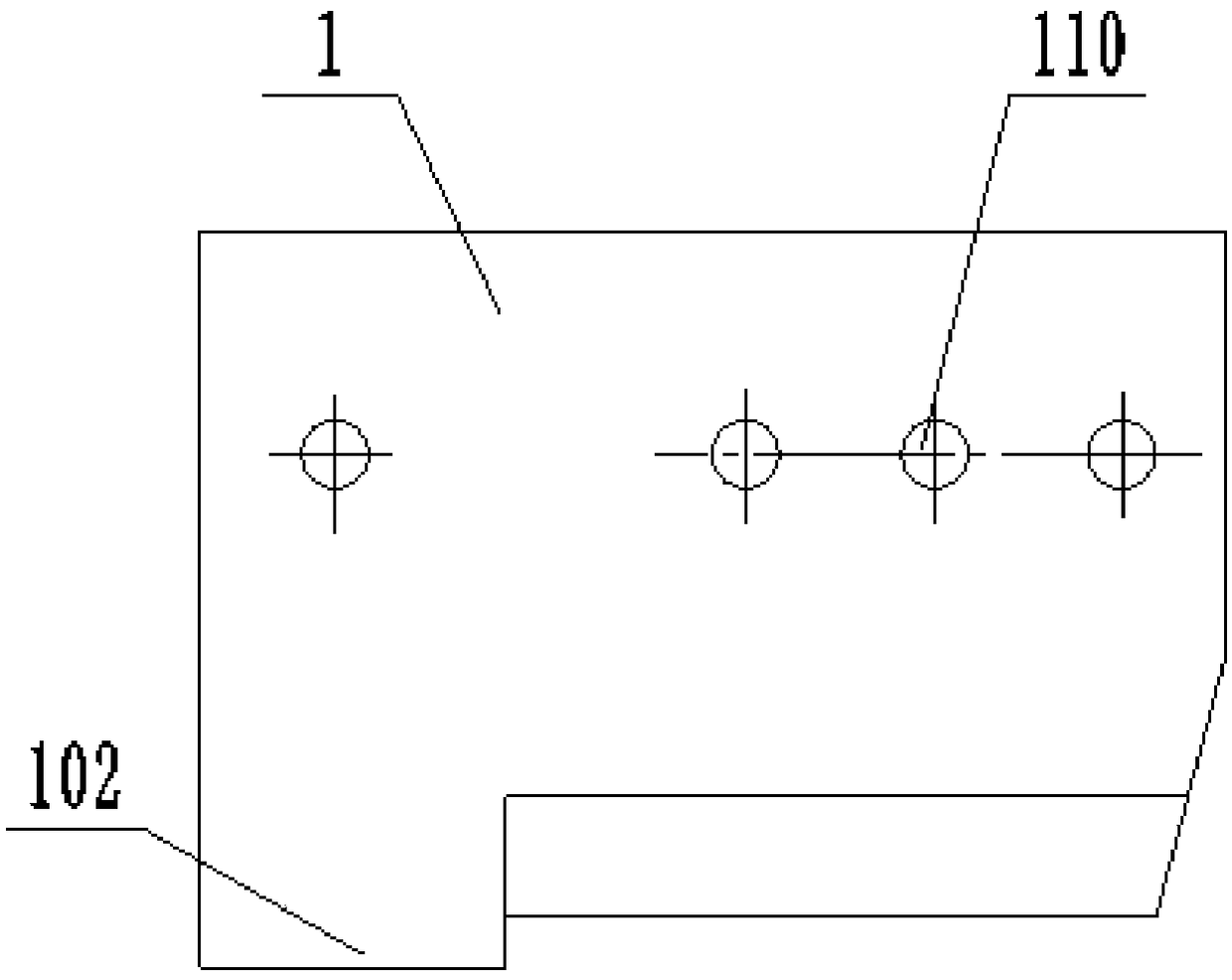

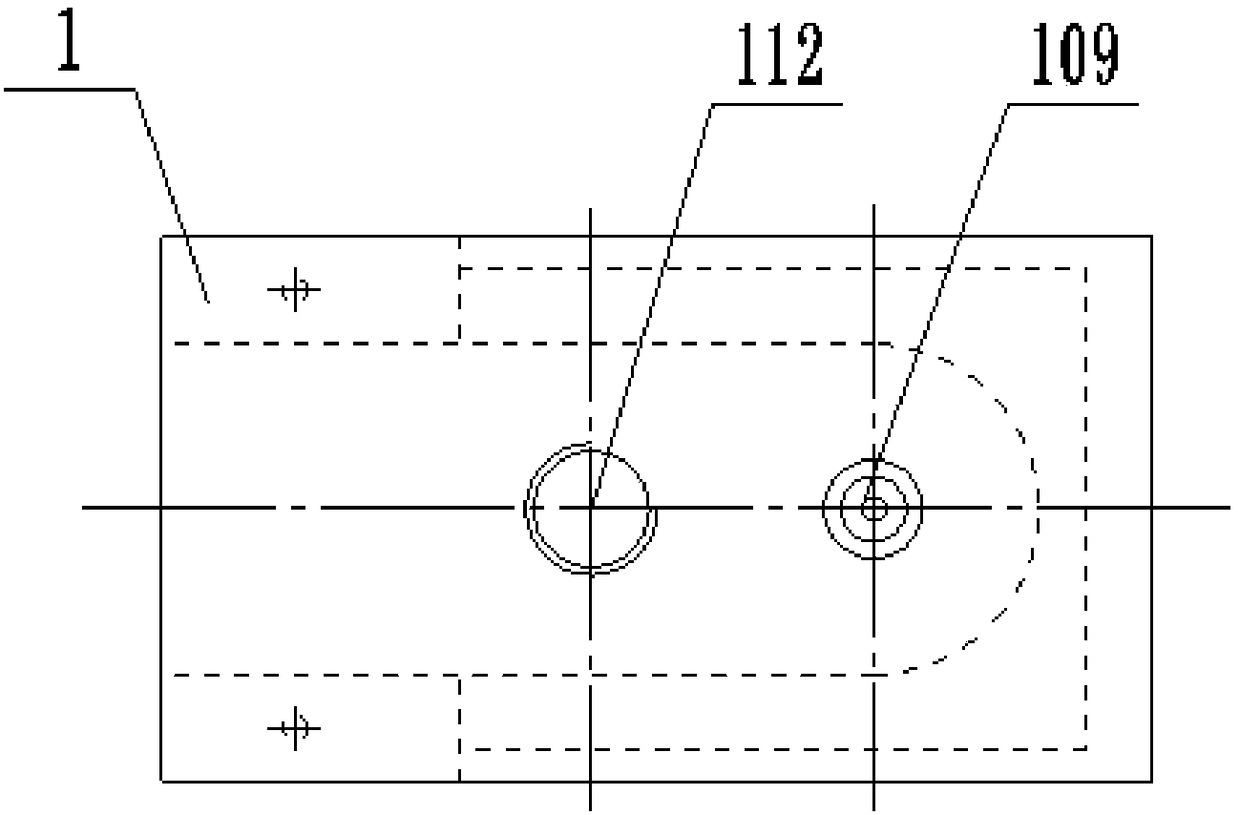

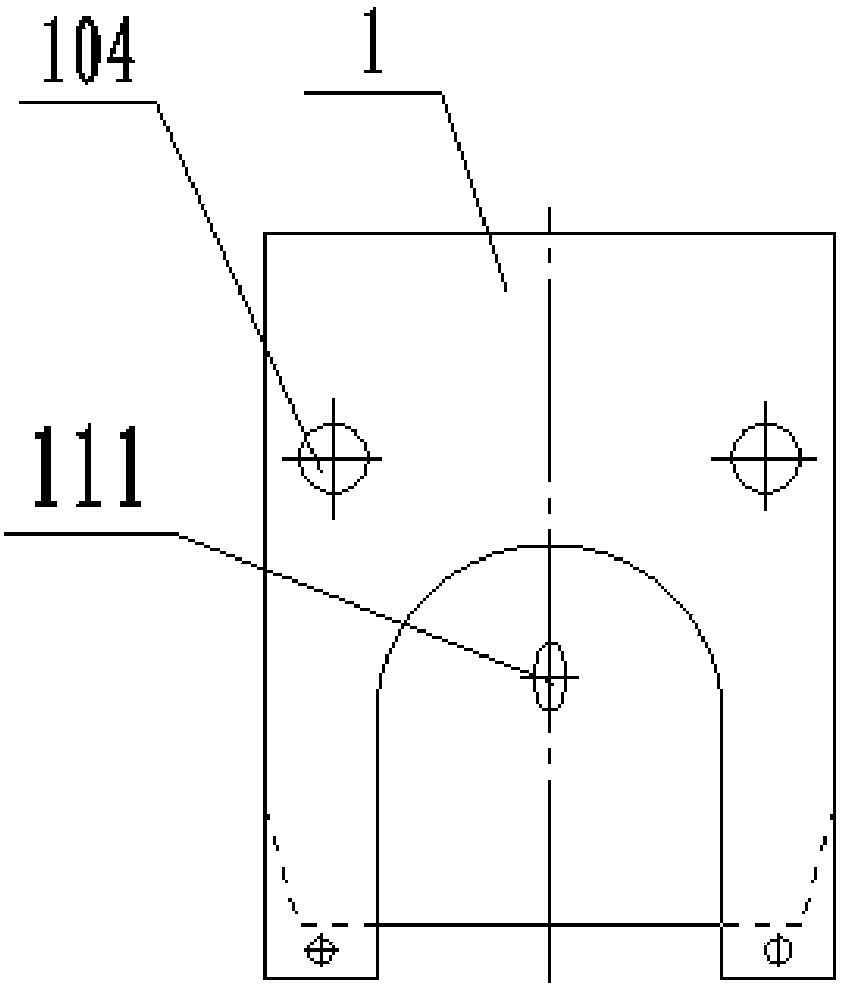

[0053] Such as Figure 1 to Figure 9 As shown, this embodiment provides a welding protection device for an air conditioner liquid reservoir, including an outer ventilation block 1 and an inner ventilation block 2; Groove 101, the groove 101 is matched with the outlet pipe of the liquid reservoir, the left end of the bottom surface of the outer ventilation block 1 is provided with a boss 102, and the bosses 102 on both sides of the groove 101 are symmetrically provided with two transverse air blowing holes 103, The horizontal air blowing hole 103 is connected to the right end surface of the boss 102; two air distribution channels 104 are arranged symmetrically on both sides above the groove 101 in the outer ventilation block 1, and the horizontal air blowing hole 103 passes through the air passing hole 105 and the air distribution channel. 104 connected; the right side of the boss 102 in the outer ventilation block 1 is symmetrically distributed along the length direction with ...

Embodiment 2

[0059] This embodiment provides a method for using a welding protection device for an air-conditioning liquid storage device. The device adopts the welding protection device for an air-conditioning liquid storage device in Embodiment 1, and is used for welding the cylinder body of the liquid storage device and the air outlet pipe. The air outlet pipes are made of steel. The part of the air outlet pipe inside the cylinder is a straight pipe, and the part outside the cylinder is a 90° elbow. The outer diameter of the air outlet pipe is φ15mm, the wall thickness is 1mm, and the wall thickness of the cylinder is 1.5mm. mm, the welding clearance between the cylinder body and the outlet pipe is 0.1mm, and the matching length of the welding section is 5mm. The automatic turntable brazing machine is used to weld by flame brazing. The specific operation steps are as follows:

[0060] ① Ultrasonic cleaning is performed on the barrel and outlet pipe of the liquid receiver to be welded to...

Embodiment 3

[0078] This embodiment provides a method for using a welding protection device for an air-conditioning liquid storage device. The device adopts the welding protection device for an air-conditioning liquid storage device in Embodiment 1, and is used for welding the cylinder body of the liquid storage device and the air outlet pipe. The air outlet pipes are all made of steel. The part of the air outlet pipe located inside the cylinder is a straight pipe, and the part outside the cylinder is a 90° elbow. The outer diameter of the air outlet pipe is φ12mm, and the wall thickness is 0.8mm. The wall thickness of the cylinder is 1.6mm, the welding clearance between the cylinder body and the outlet pipe is 0.2mm, and the matching length of the welding section is 7mm. The automatic turntable brazing machine is used to weld by flame brazing. The specific operation steps are as follows:

[0079] ① Ultrasonic cleaning is performed on the barrel and outlet pipe of the liquid receiver to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com