A kind of preparation method of solder paste

A solder paste and ultrasonic technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as high-temperature melting, and achieve the effect of full solder joints, uniform grain distribution, and rapid removal of solder paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Add the raw materials for making solder paste into the reaction kettle, mix these raw materials evenly, heat and stir at 80°C for 1 hour after preliminary mixing, and the stirring speed is 0.1m / s, and prepare the initial solder paste reactant. Start the circulation pump to transfer the initial reactant to the ultrasonic treatment system, control the temperature of the material to 80°C through the constant temperature device, the power of the ultrasonic generator is 2kW, the frequency of the ultrasonic wave generated is 30kHz, and the ultrasonic treatment time is 4h, and the intermediate solder paste is prepared body. Then, adjust the power of the ultrasonic generator to 0.5kW, the frequency of the generated ultrasonic waves to 25kHz, and the ultrasonic cooling time to 0.5h. At this time, the temperature of the solder paste reaches room temperature to prepare the solder paste, which is then packaged and stored.

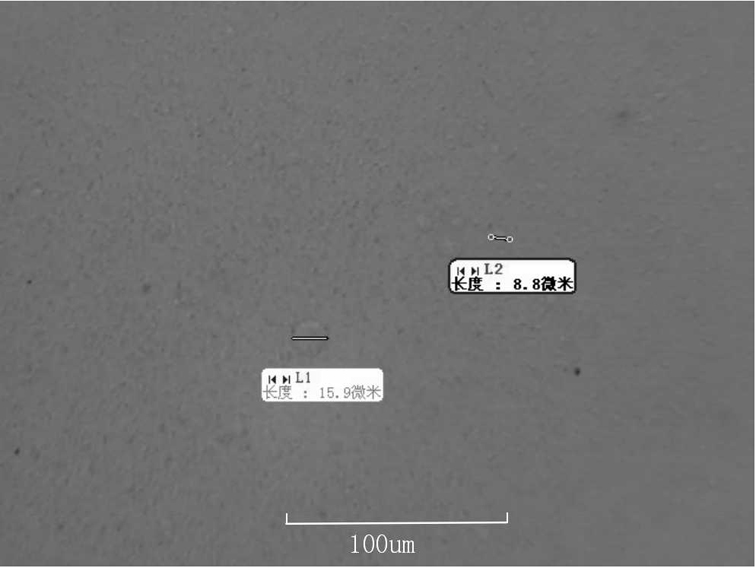

[0043] attached figure 1 It is the morphology...

Embodiment 2

[0044] Example 2: Add the raw materials for making solder paste into the reaction kettle, mix these raw materials evenly, heat and stir at 100°C for 0.5h after preliminary mixing, and the stirring speed is 0.5m / s to prepare solder paste initial reactant. Start the circulation pump to transfer the initial reactant to the ultrasonic treatment system, control the temperature of the material to 100°C through the constant temperature device, the power of the ultrasonic generator is 6kW, the frequency of the ultrasonic wave generated is 20kHz, and the ultrasonic treatment time is 2h, and the intermediate solder paste is prepared body. Then, adjust the power of the ultrasonic generator to 0.2kW, the frequency of the generated ultrasonic waves to 20kHz, and the ultrasonic cooling time to 2h. At this time, the temperature of the solder paste reaches room temperature to prepare the solder paste, and then pack it for storage.

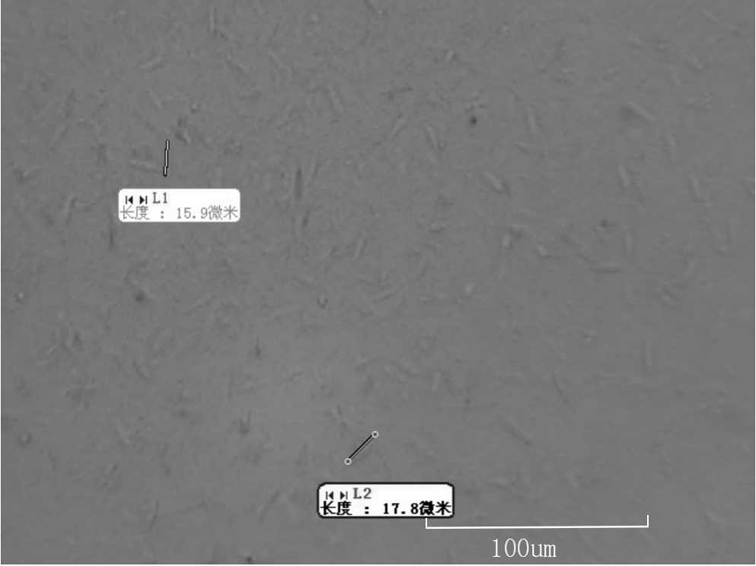

[0045] attached image 3 It is the topography diagram of t...

Embodiment 3

[0046] Example 3: Add the raw materials for making solder paste into the reaction kettle, mix these raw materials evenly, heat and stir at 100°C for 0.5h after preliminary mixing, and the stirring speed is 1m / s, and prepare the initial solder paste reactant. Start the circulating pump to transfer the initial reactant to the ultrasonic treatment system, control the temperature of the material to 100°C through the constant temperature device, the power of the ultrasonic generator is 8kW, the frequency of the ultrasonic wave generated is 20kHz, and the ultrasonic treatment time is 1h, and the intermediate solder paste is prepared body. Then, adjust the power of the ultrasonic generator to 0.5kW, the frequency of the generated ultrasonic waves to 20kHz, and the ultrasonic cooling time to 2h. At this time, the temperature of the solder paste reaches room temperature to prepare the solder paste, and then pack it for storage.

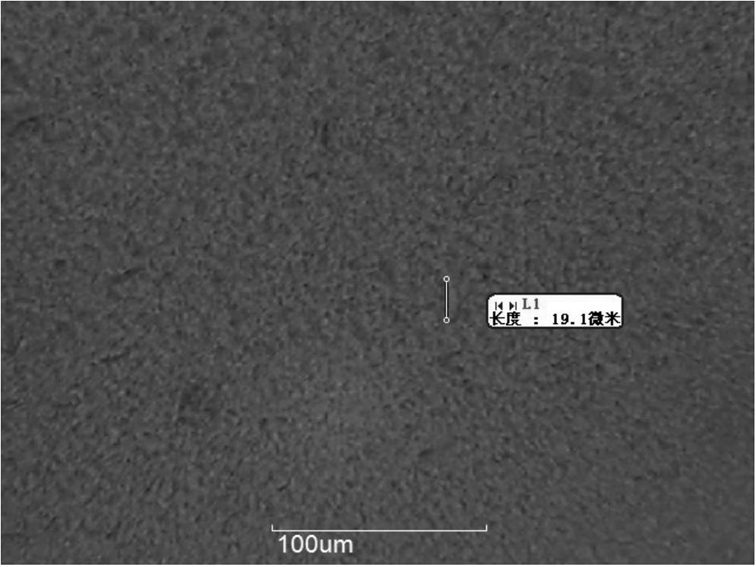

[0047] attached Figure 4 It is the topography diagram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com