Water-base scaling powder and preparation method and application thereof

A flux, water-based technology, used in welding equipment, welding media, manufacturing tools, etc., can solve problems such as unsafe operability and fried tin, and achieve the effects of no harm to the human body, low smoke, and strong wetting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] On the other hand, the embodiment of the present invention also provides a preparation method of the above-mentioned water-based flux. Described preparation method comprises the steps:

[0031] Step S01: Measure the raw materials of each component according to the components and content ratios contained in the water-based flux mentioned above;

[0032] Step S02: after dissolving the measured water-soluble rosin resin component raw material in the measured organic solvent component raw material, adding deionized water for mixing treatment to prepare a first mixed solution;

[0033] Step S03: mixing the measured organic acid component raw materials with the first mixed solution to prepare a second mixed solution;

[0034] Step S04: Mixing the measured compounded surfactant and other additives with the second mixed solution.

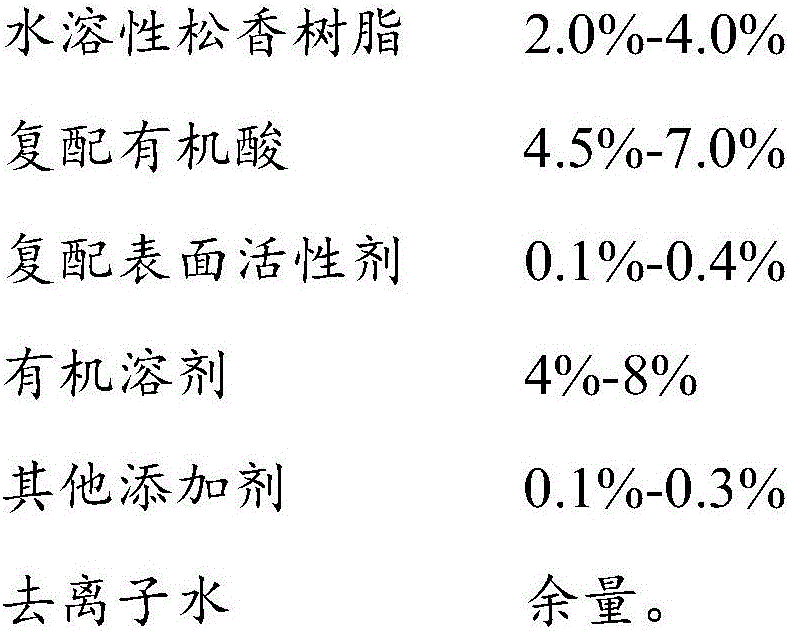

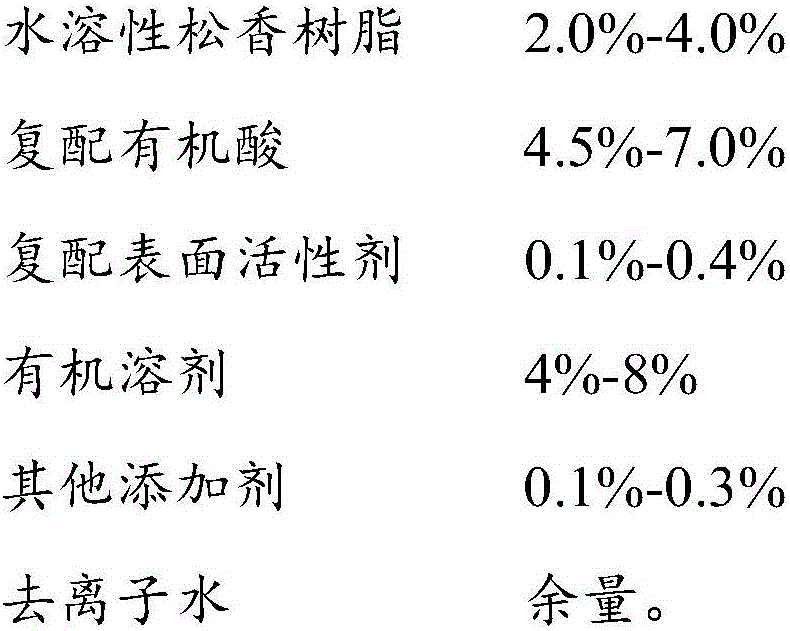

[0035] Specifically, the components and content ratios of the water-based flux described in the above step S01 are the same as those described abo...

Embodiment 1

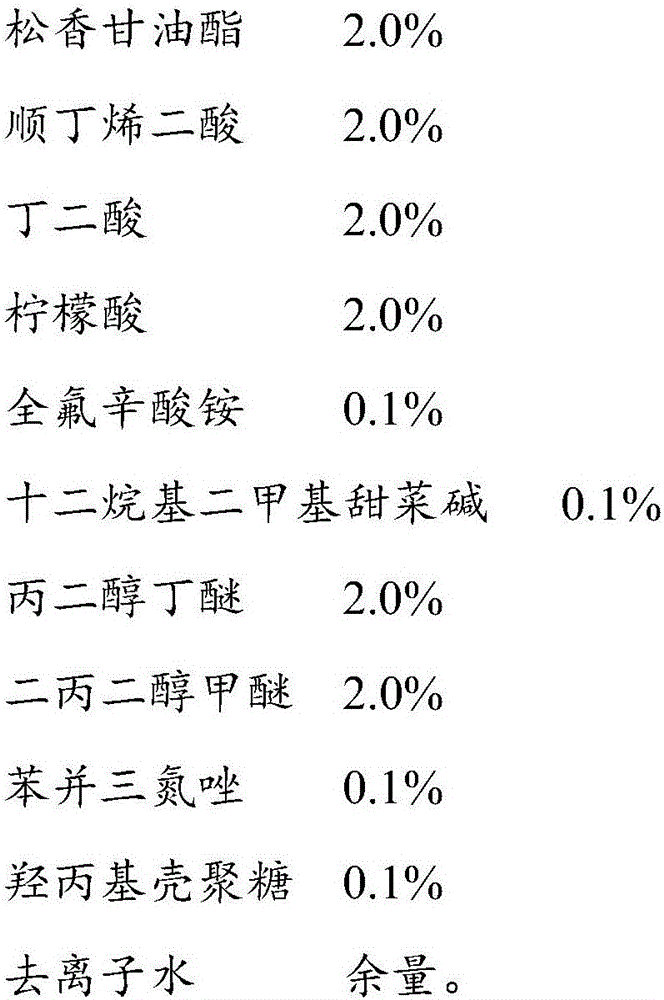

[0041] This embodiment provides a water-based flux, which consists of the following components in mass percent:

[0042]

[0043] The preparation method of this water-based soldering flux comprises the steps:

[0044] S11: Mix propylene glycol butyl ether and dipropylene glycol methyl ether evenly, add rosin glyceride into the mixed solvent, stir at high speed until completely dissolved, then add deionized water, stir and mix evenly;

[0045] S12: Add maleic acid, succinic acid, and citric acid into step S11 one by one, and stir until completely dissolved;

[0046] S13: Mix ammonium perfluorooctanoate and dodecyl dimethyl betaine evenly, then add to step S12, and stir until completely dissolved.

[0047] S14: Add additives benzotriazole and hydroxypropyl chitosan one by one to step S13, stir until completely dissolved to obtain the product.

Embodiment 2

[0049] This embodiment provides a water-based flux, which consists of the following components in mass percent:

[0050]

[0051]

[0052] The preparation method of this water-based soldering flux comprises the steps:

[0053] S21: Mix dipropylene glycol butyl ether and tripropylene glycol methyl ether evenly, add rosin pentaerythritol ester into the mixed solvent, stir at high speed until completely dissolved, then add deionized water, stir and mix evenly;

[0054] S22: Add maleic acid, succinic acid, and citric acid into step S21 one by one, and stir until completely dissolved;

[0055] S23: Mix perfluorononanoic acid ammonium and dodecyl dihydroxyethyl betaine evenly, then add to step S22, and stir until completely dissolved.

[0056] S24: adding the additives benzotriazepine and hydroxypropyl chitosan into step S23 one by one, stirring until completely dissolved to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com