Wash-free soldering flux

A flux and no-cleaning technology, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of low efficiency and high cost, achieve low spatter value, good welding quality, and smooth and bright solder joints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

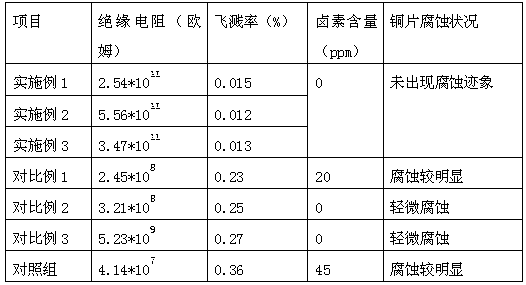

Examples

Embodiment 1

[0014] A no-clean flux, which contains the following components in terms of mass percentage: 7.0% film-forming agent, 3.5% active agent, 0.3% surfactant, 0.20% corrosion inhibitor, 0.45% additive, and the rest Solvent, mix the above ingredients evenly, heat to 70°C, reflux and stir for 2 hours, cool to 20°C, and filter to obtain the product, wherein the film-forming agent is composed of the following ingredients in parts by weight: 45 parts of amino acid ester, 30 parts of glyceryl monostearate, 25 parts of epoxy resin, 20 parts of naphthalene diphenol resin, and 15 parts of bishydroxybiphenyl resin.

[0015] As a further description of the above scheme, the active agent is composed of the following components in parts by weight: 12 parts of adipic acid, 13 parts of sebacic acid, 15 parts of salicylic acid, 18 parts of stearic acid, 21 parts of boric acid, three 24 parts of ethanolamine.

[0016] As a further description of the above solution, the solvent consists of the foll...

Embodiment 2

[0021] A no-clean flux containing the following components in terms of mass percentage: 8.0% film-forming agent, 3.8% active agent, 0.35% surfactant, 0.23% corrosion inhibitor, 0.48% additive, and the rest Solvent, mix the above ingredients evenly, heat to 75°C, reflux and stir for 2.3 hours, cool to 23°C, and filter to obtain the product, wherein the film-forming agent is composed of the following ingredients in parts by weight: 50 parts of amino acid ester, 33 parts of glyceryl monostearate, 28 parts of epoxy resin, 23 parts of naphthalene diphenol resin, and 17 parts of bishydroxybiphenyl resin.

[0022] As a further description of the above scheme, the active agent is composed of the following components in parts by weight: 13 parts of adipic acid, 14 parts of sebacic acid, 16 parts of salicylic acid, 19 parts of stearic acid, 22 parts of boric acid, three 25 parts of ethanolamine.

[0023] As a further description of the above scheme, the solvent consists of the followin...

Embodiment 3

[0028] A no-clean flux containing the following components in terms of mass percentage: 8.5% film-forming agent, 4.0% active agent, 0.4% surfactant, 0.25% corrosion inhibitor, 0.50% additive, and the rest Solvent, mix the above ingredients evenly, heat to 80°C, reflux and stir for 2.5 hours, cool to 25°C, and filter to obtain the product, wherein the film-forming agent consists of the following ingredients in parts by weight: 55 parts of amino acid ester, 35 parts of glyceryl monostearate, 30 parts of epoxy resin, 25 parts of naphthalene diphenol resin, and 20 parts of bishydroxybiphenyl resin.

[0029] As a further description of the above scheme, the active agent consists of the following components in parts by weight: 15 parts of adipic acid, 15 parts of sebacic acid, 18 parts of salicylic acid, 20 parts of stearic acid, 23 parts of boric acid, three 26 parts of ethanolamine.

[0030] As a further description of the above scheme, the solvent consists of the following compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com