Method for preparing polytetrafluoroethylene copper-clad plate

A technology of polytetrafluoroethylene and copper clad laminates, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of small surface insulation resistance, high loss factor, low peel strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing polyethylene copper-clad laminates, comprising pretreatment of glass fiber cloth, preparation of dipping solution, dipping of glass fiber cloth to obtain medium cloth and medium cloth coated with copper and aluminum, medium cloth covered with copper and aluminum, the medium Cloth clad copper clad aluminum includes the following steps:

[0025] a. Cut the dielectric cloth, copper foil and aluminum foil into 330mm×460mm specifications;

[0026] b. Lay aluminum foil, copper foil, dielectric cloth, copper foil, and aluminum foil on the template in sequence, and then put it into a hot press machine. Keep this state for 2.5 hours and then cool naturally. When the temperature is cooled to 200° C., quench for 30 minutes to obtain the modified polytetrafluoroethylene copper-clad laminate.

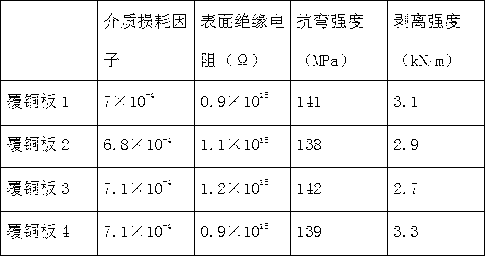

[0027] Each material performance index described in the present invention is as follows:

[0028] Polytetrafluoroethylene concentrated dispersion: FR301G, solid conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com