Welding-aiding agent for circuit board welding and preparation method thereof

A flux and circuit board technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of high residue and low cost, and achieve less residue, good dryness, and low ionic pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

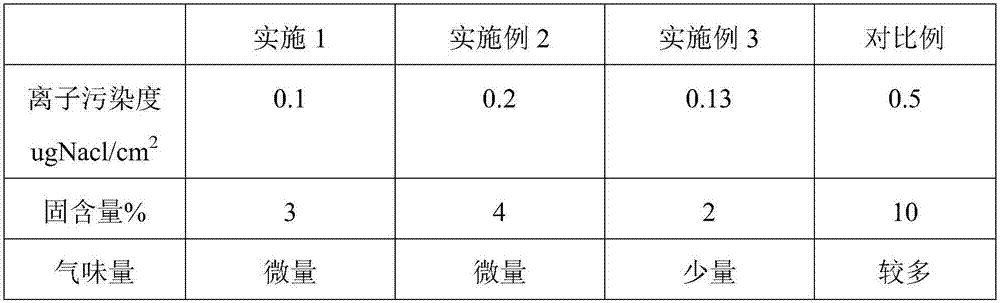

Examples

Embodiment 1

[0020] A flux used for circuit board welding, comprising the following components in parts by weight: 20 parts of cerium oxide, 2 parts of oxalic acid, 3 parts of butyl acetate, 1 part of corundum powder, 1 part of fluorocarbon sub-surfactant, 2 parts of potassium carbonate, 2 parts of sodium carbonate, 5 parts of hydroxy organic acid, 3 parts of formate ester, 2 parts of alcohol amine, 3 parts of glyceryl monostearate, 0.5 part of polyisobutylene succinimide, antioxidant 3 copies.

[0021] The hydroxy organic acid is two or more of water-soluble citric acid, DL-malic acid, tartaric acid, glycolic acid; the alcohol amine is one of triethanolamine, triisopropanolamine or their composition.

[0022] The purity of the cerium oxide is greater than 99.0%.

[0023] Described antioxidant is 2,6-di-tert-butyl p-cresol, hydroquinone, 2-tert-butyl hydroquinone, 2-tert-butyl-4-methoxyphenol and 3-tert-butyl One or more of butyl-4-methoxyphenol.

[0024] A preparation method for solde...

Embodiment 2

[0032] A soldering flux for circuit board welding, comprising the following components in parts by weight: 25 parts of cerium oxide, 6 parts of oxalic acid, 5 parts of butyl acetate, 2 parts of corundum powder, 3 parts of fluorocarbon sub-surfactant, 9 parts of potassium carbonate, 8 parts of sodium carbonate, 12 parts of hydroxy organic acid, 6 parts of formate ester, 6 parts of alcohol amine, 6 parts of glyceryl monostearate, 1.5 parts of polyisobutylene succinimide, antioxidant 7 servings.

[0033] The hydroxy organic acid is two or more of water-soluble citric acid, DL-malic acid, tartaric acid, glycolic acid; the alcohol amine is one of triethanolamine, triisopropanolamine or their composition.

[0034] The purity of the cerium oxide is greater than 99.0%.

[0035] Described antioxidant is 2,6-di-tert-butyl p-cresol, hydroquinone, 2-tert-butyl hydroquinone, 2-tert-butyl-4-methoxyphenol and 3-tert-butyl One or more of butyl-4-methoxyphenol.

[0036] A preparation metho...

Embodiment 3

[0044] A soldering flux for circuit board welding, comprising the following components in parts by weight: 30 parts of cerium oxide, 10 parts of oxalic acid, 8 parts of butyl acetate, 3 parts of corundum powder, 5 parts of fluorocarbon sub-surfactant, 15 parts of potassium carbonate, 12 parts of sodium carbonate, 18 parts of hydroxy organic acid, 9 parts of formate ester, 10 parts of alcohol amine, 9 parts of glyceryl monostearate, 2.5 parts of polyisobutylene succinimide, antioxidant 10 servings.

[0045] The hydroxy organic acid is two or more of water-soluble citric acid, DL-malic acid, tartaric acid, glycolic acid; the alcohol amine is one of triethanolamine, triisopropanolamine or their composition.

[0046] The purity of the cerium oxide is greater than 99.0%.

[0047] Described antioxidant is 2,6-di-tert-butyl p-cresol, hydroquinone, 2-tert-butyl hydroquinone, 2-tert-butyl-4-methoxyphenol and 3-tert-butyl One or more of butyl-4-methoxyphenol.

[0048] A preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com