Soldering paste and soldering flux thereof, and preparation methods thereof

A technology of flux and solder paste, used in manufacturing tools, welding media, welding equipment, etc., can solve problems such as failure to pass the probe test and difficulty in solder paste, and achieve the effect of improving the pass rate of the probe test and improving the welding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

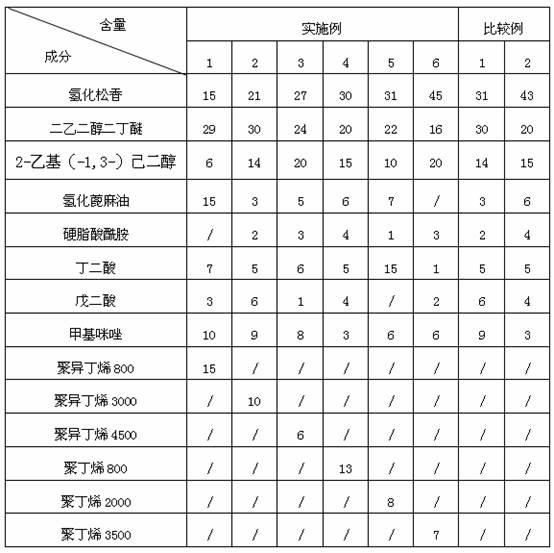

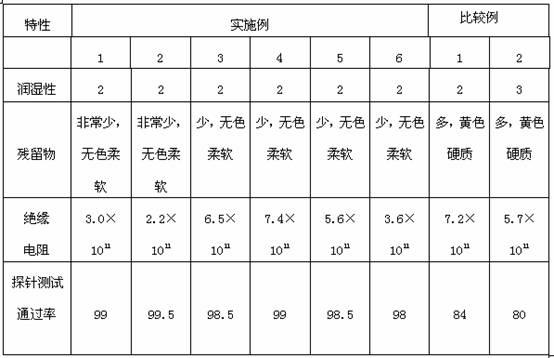

Embodiment 1

[0056] First, weigh 15 parts by weight of hydrogenated rosin, 29 parts by weight of diethylene glycol dibutyl ether, 6 parts by weight of 2-ethyl (-1,3-) hexanediol, and 15 parts by weight of hydrogenated castor oil into a stainless steel container Internal heating to 130°C ~ 150°C, and stirring until completely melted. Next, the temperature of the stainless steel container was lowered to 110° C. to 130° C., and then 7 parts by weight of succinic acid and 3 parts by weight of glutaric acid were added into the stainless steel container and stirred until completely melted. Next, the temperature of the stainless steel container was further lowered to 70°C to 90°C, and then 10 parts by weight of methylimidazole and 15 parts by weight of polyisobutylene 800 were added into the stainless steel container, stirred until completely melted, and then cooled to prepare flux. Finally, fully stir and mix the lead-free solder powder and flux in a vacuum mixer to obtain a solder paste.

Embodiment 2

[0058]First, 21 parts by weight of hydrogenated rosin, 30 parts by weight of diethylene glycol dibutyl ether, 14 parts by weight of 2-ethyl (-1,3-) hexanediol, 3 parts by weight of hydrogenated castor oil, 2 parts by weight of stearin The acid amide is weighed and placed in a stainless steel container, heated to 130°C to 150°C, and stirred until completely melted. Next, the temperature of the stainless steel container was lowered to 110° C. to 130° C., and then 5 parts by weight of succinic acid and 6 parts by weight of glutaric acid were added into the stainless steel container and stirred until completely melted. Next, the temperature of the stainless steel container was further lowered to 70°C to 90°C, and then 9 parts by weight of methylimidazole and 10 parts by weight of polyisobutylene 3000 were added into the stainless steel container, stirred until completely melted, and then cooled to prepare flux. Finally, fully stir and mix the lead-free solder powder and flux in a ...

Embodiment 3

[0060] First, 27 parts by weight of hydrogenated rosin, 24 parts by weight of diethylene glycol dibutyl ether, 20 parts by weight of 2-ethyl (-1,3-) hexanediol, 5 parts by weight of hydrogenated castor oil, 3 parts by weight of stearin The acid amide is weighed and placed in a stainless steel container, heated to 130°C to 150°C, and stirred until completely melted. Next, the temperature of the stainless steel container was lowered to 110° C. to 130° C., and then 6 parts by weight of succinic acid and 1 part by weight of glutaric acid were added into the stainless steel container and stirred until completely melted. Next, the temperature of the stainless steel container was further lowered to 70°C to 90°C, and then 8 parts by weight of methylimidazole and 6 parts by weight of polyisobutylene 4500 were added into the stainless steel container, stirred until completely melted, and then cooled to prepare flux. Finally, fully stir and mix the lead-free solder powder and flux in a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com