Structural steel plate for wind power and production method thereof

A technology of structural steel plate and production method, applied in the field of structural steel plate for wind power and its production, can solve the problems of high cost, poor comprehensive performance of steel plate, long production process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

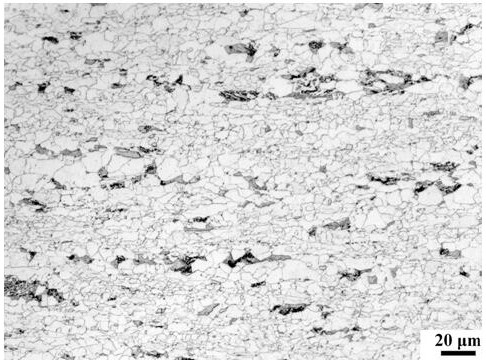

Embodiment 1

[0088] Provide a kind of steel plate, the chemical composition of steel plate comprises in mass percent: C:0.08%, Si:0.15%, Mn:1.48%, P:0.012%, S:0.004%, Cr:0.12%, Ni:0.12%, Nb: 0.014%, Ti: 0.014%, Alt: 0.035%, N: 0.0042%, the rest is iron and unavoidable impurities, carbon equivalent CEV: 0.359%.

[0089] The production method of the steel plate includes the following three steps.

[0090] (1) Heating process

[0091] The chemical composition of the continuous casting slab used includes: C: 0.08%, Si: 0.15%, Mn: 1.48%, P: 0.012%, S: 0.004%, Cr: 0.12%, Ni: 0.12%, Nb : 0.014%, Ti: 0.014%, Alt: 0.035%, N: 0.0042%, the rest is iron and unavoidable impurities, carbon equivalent CEV: 0.359%.

[0092] T is calculated by formula ① as above NbC is 1171°C, using the formula ② above to calculate T NbN is 1209°C, using the formula ③ above to calculate T nr The temperature is 909°C, and the differential scanning calorimeter (DSC) is used to test and measure A in accordance with JY / T0...

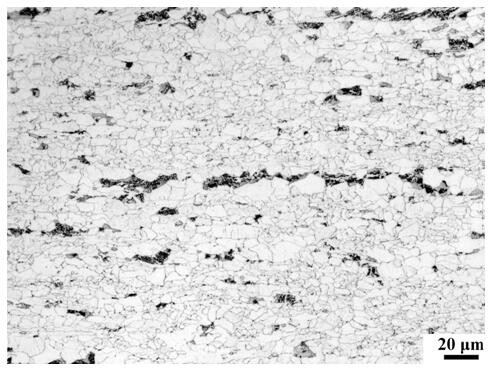

Embodiment 2

[0101] Provide a kind of steel plate, the chemical composition of steel plate comprises in mass percent: C:0.10%, Si:0.15%, Mn:1.42%, P:0.011%, S:0.004%, Cr:0.12%, Ni:0.12%, Nb: 0.014%, Ti: 0.014%, Alt: 0.035%, N: 0.0039%, the rest is iron and unavoidable impurities, carbon equivalent CEV: 0.369%.

[0102] The production method of the steel plate includes the following three steps.

[0103] (1) Heating process

[0104] The chemical composition of the continuous casting slab used includes: C: 0.10%, Si: 0.15%, Mn: 1.42%, P: 0.011%, S: 0.004%, Cr: 0.12%, Ni: 0.12%, Nb : 0.014%, Ti: 0.014%, Alt: 0.035%, N: 0.0039%, the rest is iron and unavoidable impurities, carbon equivalent CEV: 0.369%.

[0105] T is calculated by formula ① as above NbC is 1190°C, T is calculated using the formula ② above NbN is 1203°C, using the formula ③ above to calculate T nrIt is 919°C, and it is tested and measured by differential scanning calorimeter (DSC) according to JY / T0589.3-2020 industry stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com