Adjustable reducing pipe butt joint positioning device and using method thereof

A technology for positioning devices and reducing pipes, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low processing precision and low production efficiency, achieve good fixing effect, simple structure, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

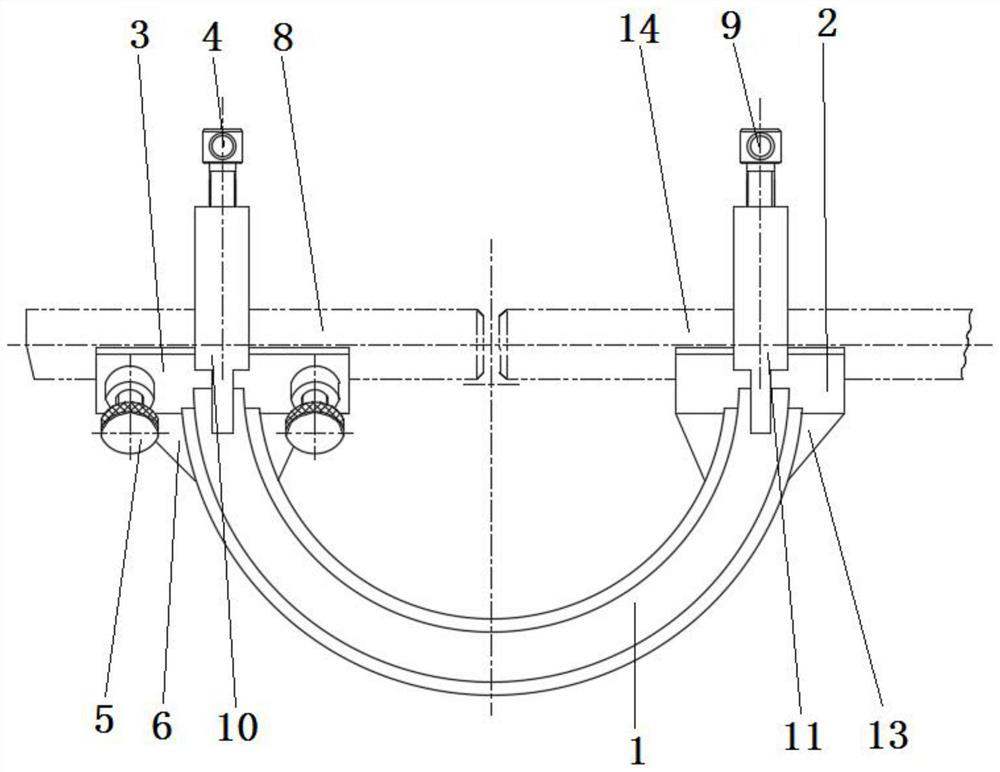

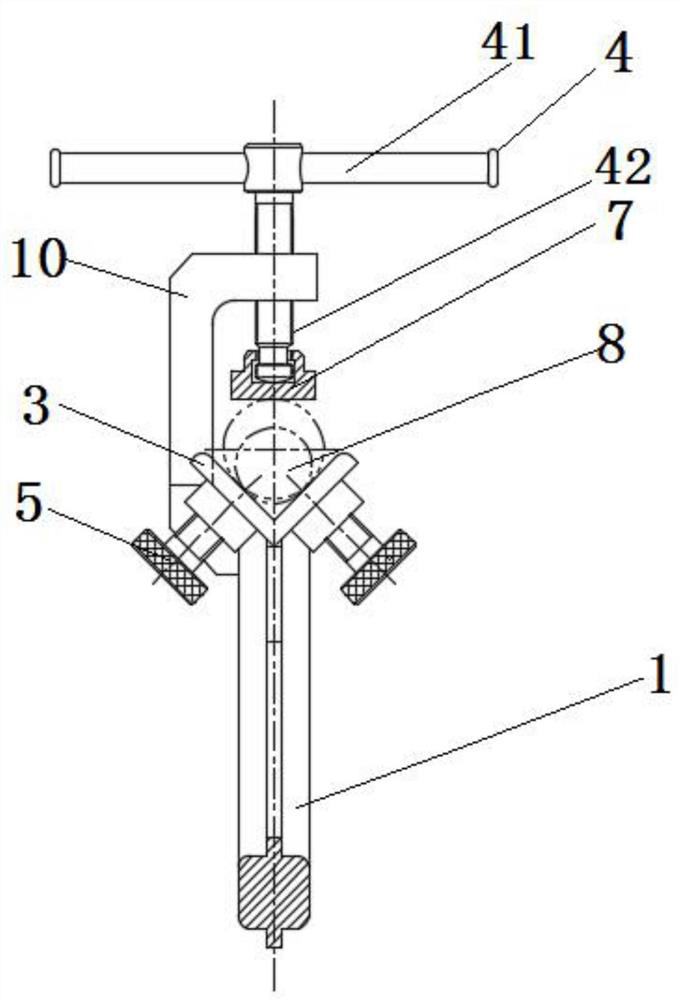

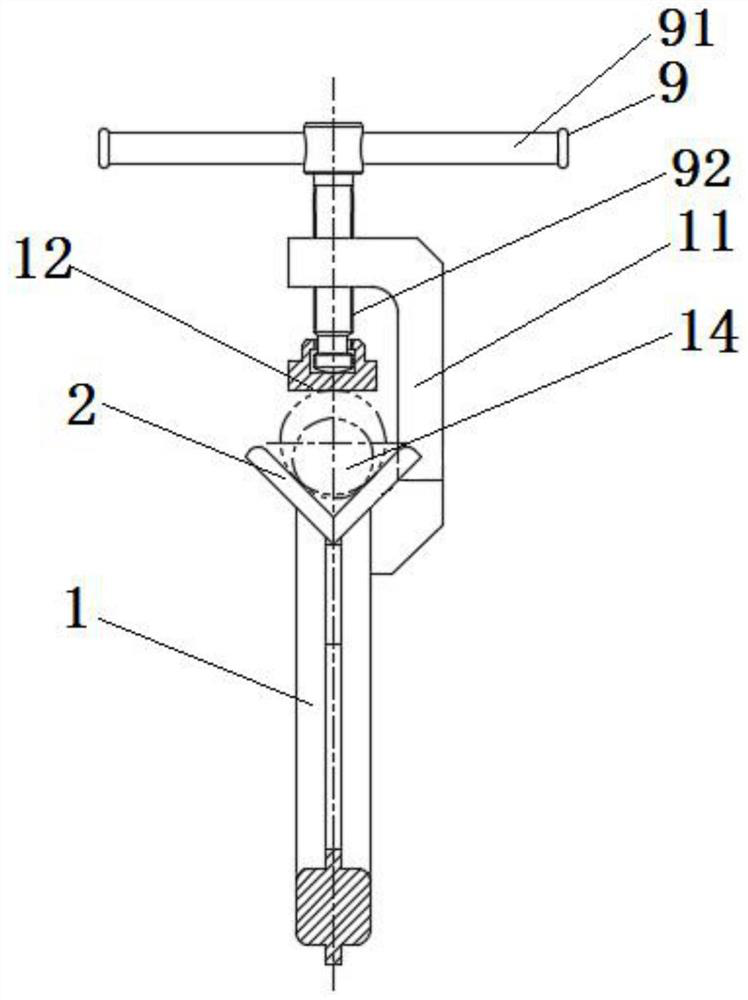

[0031] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, an adjustable butt joint positioning device for different-diameter pipes in this embodiment, including an adjustable bending plate 1, a short fixed angle steel 2, a long fixed angle steel 3, a first pressing mechanism 4, a second pressing mechanism 9, The first support arm 10 and the second support arm 11, one end of the adjustable bent plate 1 is connected with the long fixed angle steel 3, the other end of the adjusted bent plate 1 is connected with the short fixed angle steel 2, and the first pressing mechanism 4 is inserted into the first In the first threaded hole 101 of the support arm 10, the first mounting arm 10 is fixedly installed on one end of the adjustment bent plate 1, and the second pressing mechanism 9 is inserted into the second threaded hole 111 of the second support arm 11, and the second support arm 11 is fixedly installed on the other end of the adjustable bent p...

specific Embodiment approach 2

[0032] Specific implementation mode two: combination Figure 1-Figure 3 Describe this embodiment, an adjustable butt joint positioning device for different-diameter pipes in this embodiment, the bottom of the long fixed angle steel 3 is connected to the first rib 6, the bottom of the short fixed angle 2 is connected to the second rib 13, and the bottom of the fixed angle 2 is connected to the second rib 13. The first rib 6 and the second rib 13 are used to increase the rigidity of the long fixed angle 3 and the short fixed angle 2, avoiding the deformation of the long fixed angle 3 and the short fixed angle 2 due to the heavy steel pipe, which affects the welding accuracy of the steel pipe.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination Figure 1-Figure 3 Describe this embodiment, an adjustable butt joint positioning device for different-diameter pipes in this embodiment, the bottom of the first pressing mechanism 4 has a first pressing block 7, and the bottom of the second pressing mechanism 9 has a second pressing block 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com