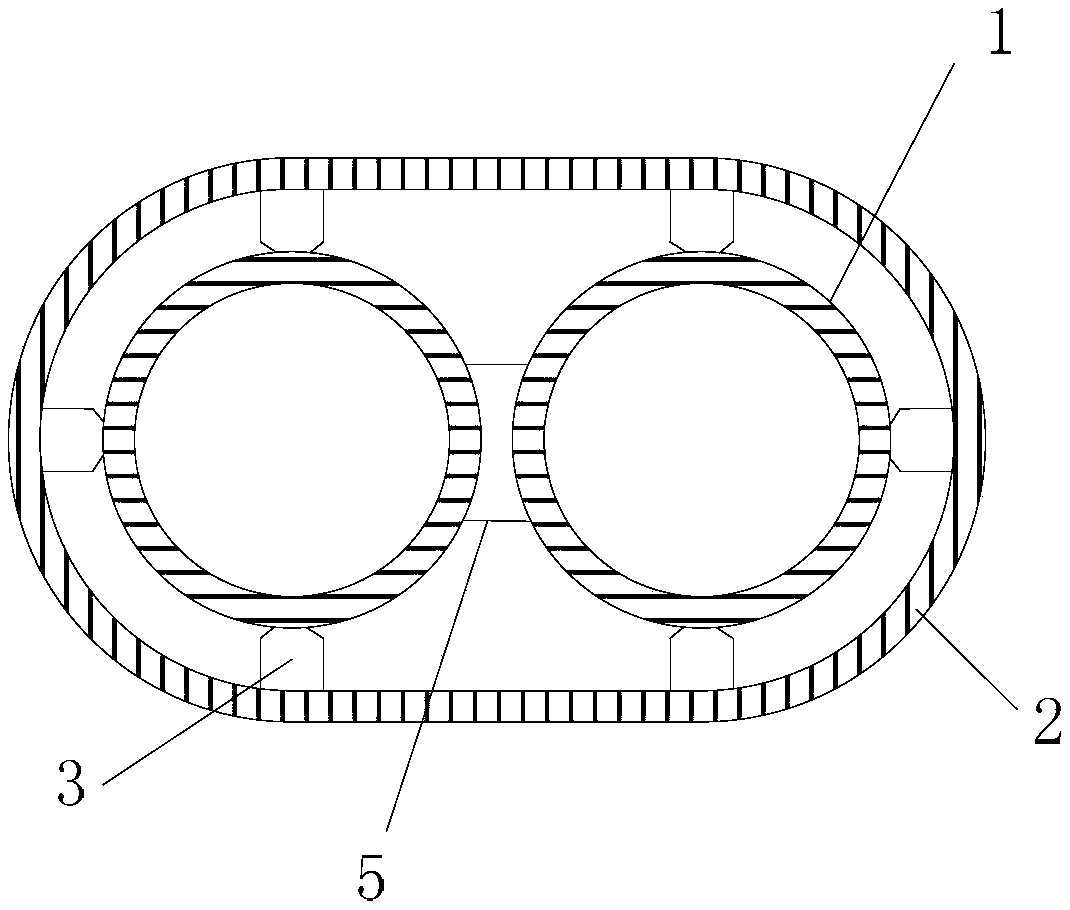

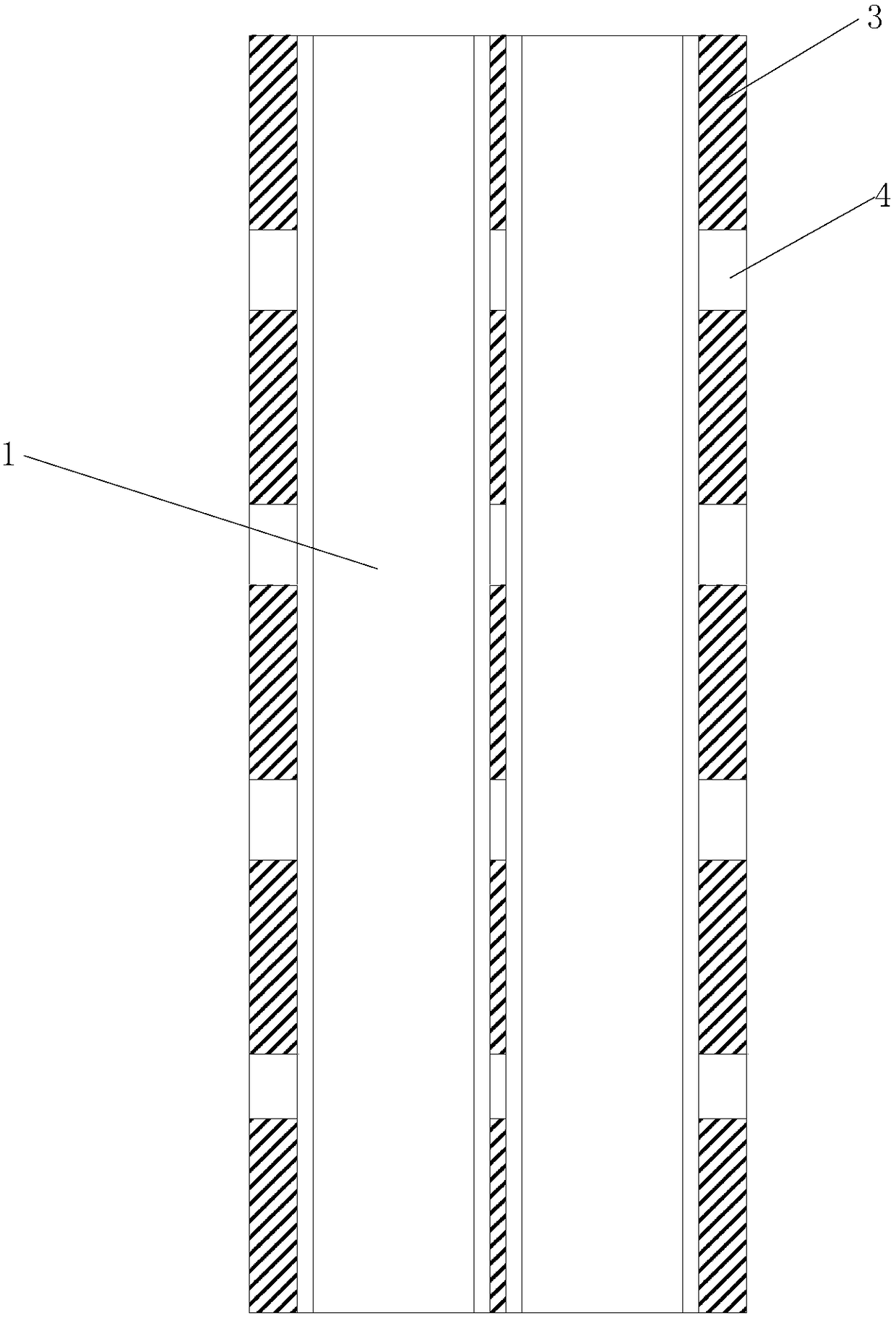

Thermal insulation dual-channel PP-R pipe

A PP-R, dual-channel technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of construction difficulty and construction cost increase, and achieve material cost saving, construction cost reduction, and good fixing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] When connecting the solar water heater, two independent inner pipes 1, one is connected to the cold water pipe, and the other is connected to the hot water pipe. Before connecting, cut the corresponding length of the pipe according to the demand, and reserve a certain margin. Use a cutter to cut the outer tube 2 from the outside as a margin, and the cutting depth is equal to the sum of the depth of the wall of the outer tube 2 and the height of the reinforcing rib; The thinnest part of the rib 3 is the connecting part with the inner tube 1, so this part is broken first, so that the inner tube 1 and the outer tube 2 can be separated.

[0021] After the outer tube 2 is peeled off, a connector can be added to the exposed inner tube 1 and connected to other pipelines or equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com