Patents

Literature

36results about How to "Good solid content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterproof-level soy protein adhesive and preparation method thereof

ActiveCN104497965AFacilitate cross-linkingImprove water resistanceProtein adhesivesGlue/gelatin preparationAdhesiveWorking life

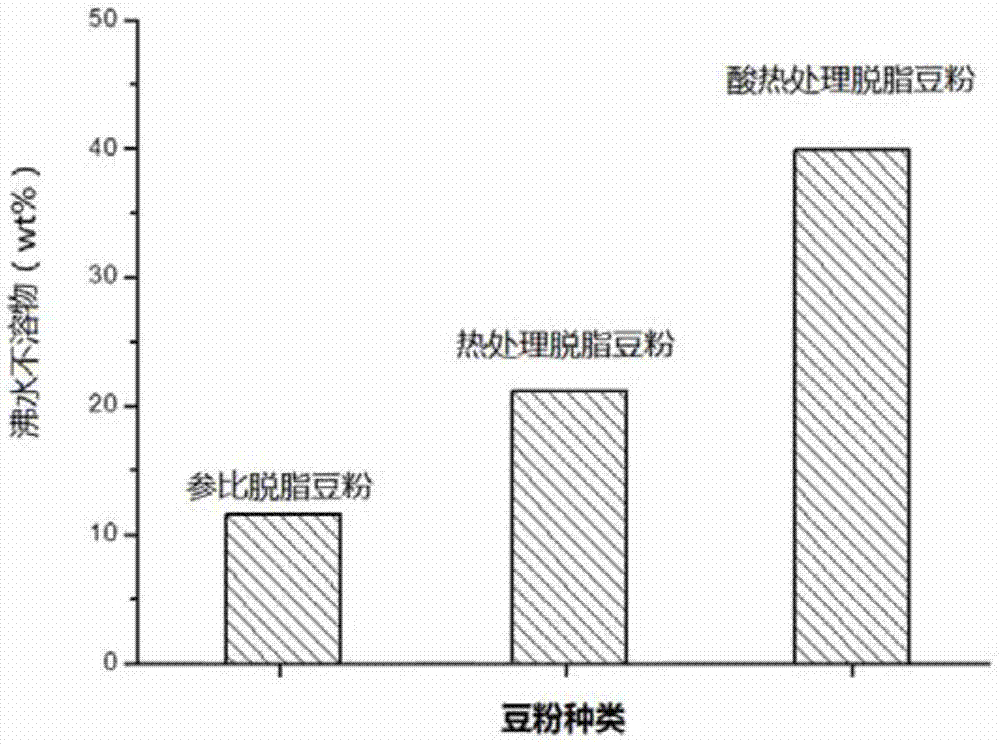

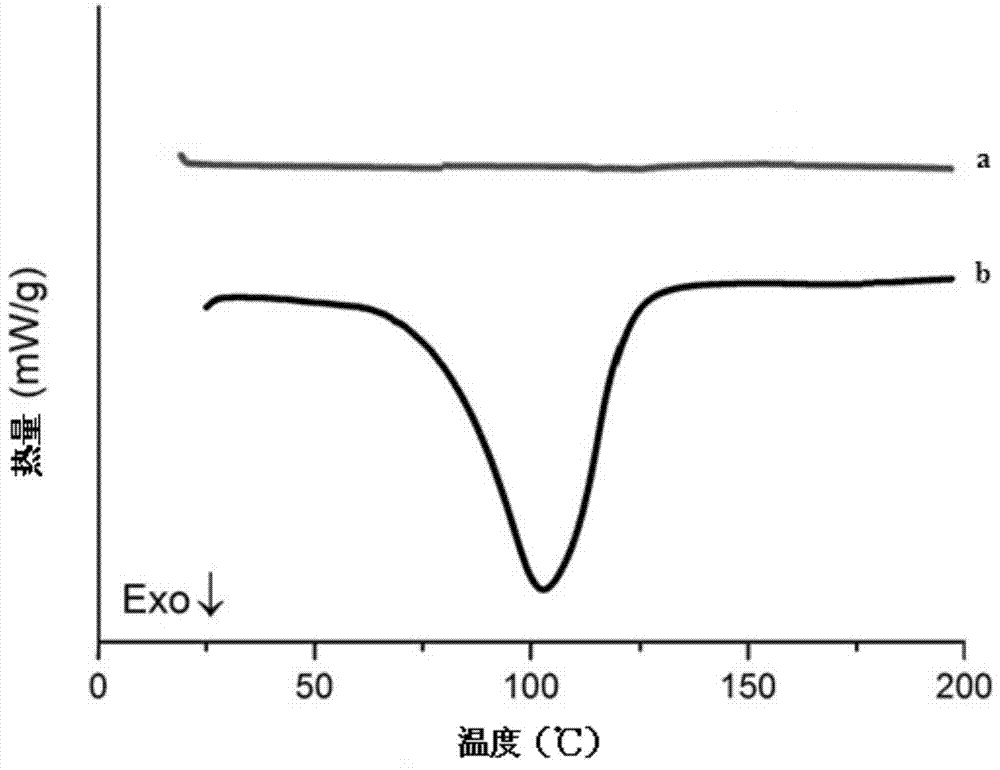

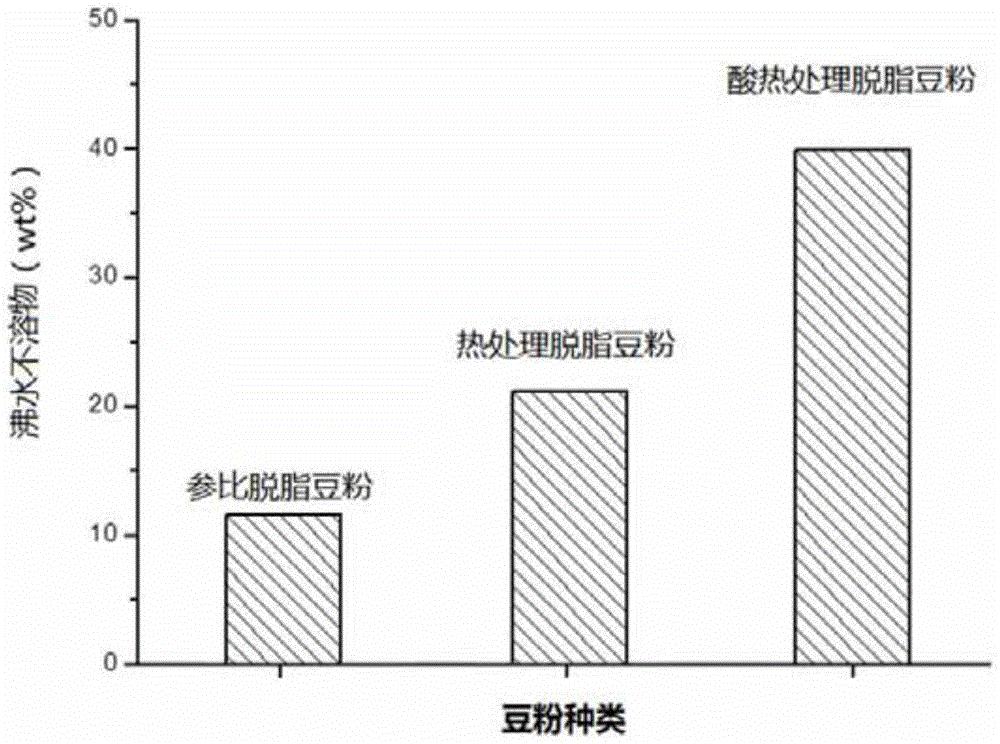

The invention provides a waterproof-level soy protein adhesive and a preparation method thereof and relates to an adhesive and a preparation method thereof, in particular to a modified soyabean protein adhesive for waterproof-level plywood. The waterproof-level soy protein adhesive aims at solving the technical problem that an existing adhesive for plywood is not waterproof. The preparation method comprises the steps of beam flour acid heat treatment, beam flour liquidation, polyamide solution synthesis and adhesive modulation. Degreased beam flour or soya bean meal left after soybean oil expelling is used as a main raw material, the water resisting property of the beam flour and the solid content of the soy protein adhesive are improved through acid heat treatment, the cross-linking efficiency, cementing effect and process usability of the soy protein adhesive are improved through liquidation, the water resisting property of the soy protein adhesive is improved through cross-linking of polyamide polyamine resin, and finally the soy protein adhesive high in beam flour content, low in viscosity, long in working life and good in water resisting property and used for the waterproof-level plywood is prepared. The waterproof-level soy protein adhesive and the preparation method belong to the field of adhesive preparation.

Owner:浙江蓝歌新材料科技有限公司

Rubber toughened SBS aldehyde removed all-purpose adhesive and preparation method thereof

InactiveCN101294053ADowngrade hazardPurify indoor airMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceThermoplastic elastomer

The invention relates to a rubber-toughened SBS formaldehyde-free universal adhesive and the preparation method thereof. The rubber-toughened SBS formaldehyde-free universal adhesive is characterized in that the adhesive is composed of linear butadiene-styrene thermoplastic elastomer 3% to 5%, star-shaped butadiene-styrene thermoplastic elastomer 7% to 9%, styrene-butadiene rubber 2.7% to 3.7%, petroleum resin 20.8% to 24.8%, formaldehyde-removing additive 1.4% to 2.6%, antioxidant 1.2% to 1.8%, petroleum ether 37% to 43%, oil solvent 16.5% to 19.5% and essence 0.4% to 0.6%. The preparation method comprises the following steps: (1) weighting the above materials according to the ratio; (2) adding styrene-butadiene rubber in the step (1) into a mixing roll machine for plasticizing, thin-passing and discharging sheets, adding the sheet material into a vertical high-speed stirring kettle, adding the oil solvent in the step (1) into the high-speed stirring kettle, dissolving, and stirring until the sheet material is dissolved completely to obtain the semi-product; and (3) respectively adding the residual material components into the stirring kettle implementing step (2), stirring and dissolving to obtain the final product. The rubber-toughened SBS formaldehyde-free universal adhesive can remove free formaldehyde released from boards and has the remarkable effects on protecting environment and maintaining human health during house decoration.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

Nano zircon oxide slurry composition and preparation process thereof

InactiveCN1450124AGood monodispersityImprove efficiencyPigment treatment with macromolecular organic compoundsAdhesive cementPhysical chemistry

The present invention relates to a nano zirconia slurry composite and its preparation method. Its composition is formed from 10-75% of nano zirconia whose average grain size is below 100nm, 0.4-15% of polymer dispersing agent and the rest is solvent. Its preparation method includes the following steps: adding the polymer dispersing agent into the solvent, then adding nano zirconia, using high-speed dispersing machine to disperse them for 10-70 min. at 400-2200 rpm. and grinding obtained slurry material for 15 min.-30 hr. so as to obtain the invented nano zirconia slurry finished product with good dispersion property and high stability. It can be extensively used in the fields of ceramics, paint, printing ink textile, cosmetics and adhesive, etc.

Owner:中科纳米涂料技术(苏州)有限公司

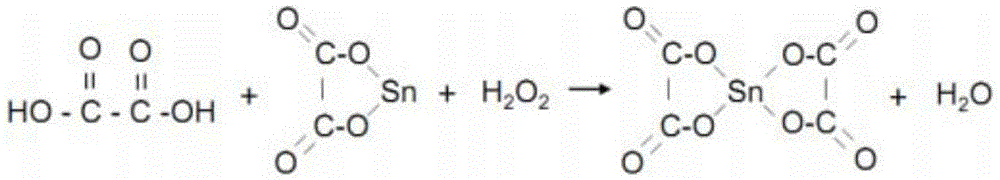

Low-temperature, halogen-free, low-solid-content modified rosin-type welding flux and preparation method thereof

InactiveCN108817731AGood solid contentSolid content modified rosin type flux has good fluidityWelding/cutting media/materialsSoldering mediaPrecipitationCorrosion

The invention relates to a low-temperature, halogen-free, low-solid-content modified rosin-type welding flux. The welding flux is prepared form, by mass, 10-15% of modified rosin, 1-5% of organic acidactivator, 0.35-1% of glycerin, 0.009-1% of benzotriazole, 0.3-1 % of triethanolamine, a surfactant and the balance organic solvent, wherein the surfactant is 0.5-3% of the mass of the organic acid activator. The prepared low-temperature, halogen-free and low-solid-content modified rosin-type welding flux prepared has good fluidity, no precipitation and delamination phenomena, no halogen elements, a small amount of modified rosin, a good spreading rate, good weldability, bright and full welding spots and less residues after welding, little corrosion is caused, and cleaning is not needed; therequirements for environmental protection are met; an operation method is sample, the temperature is moderate, there are less experimental steps, the cost is low, less by-products are generated in a synthesis process and are easy to remove, and the synthesis time is short.

Owner:ZHONGYUAN ENGINEERING COLLEGE

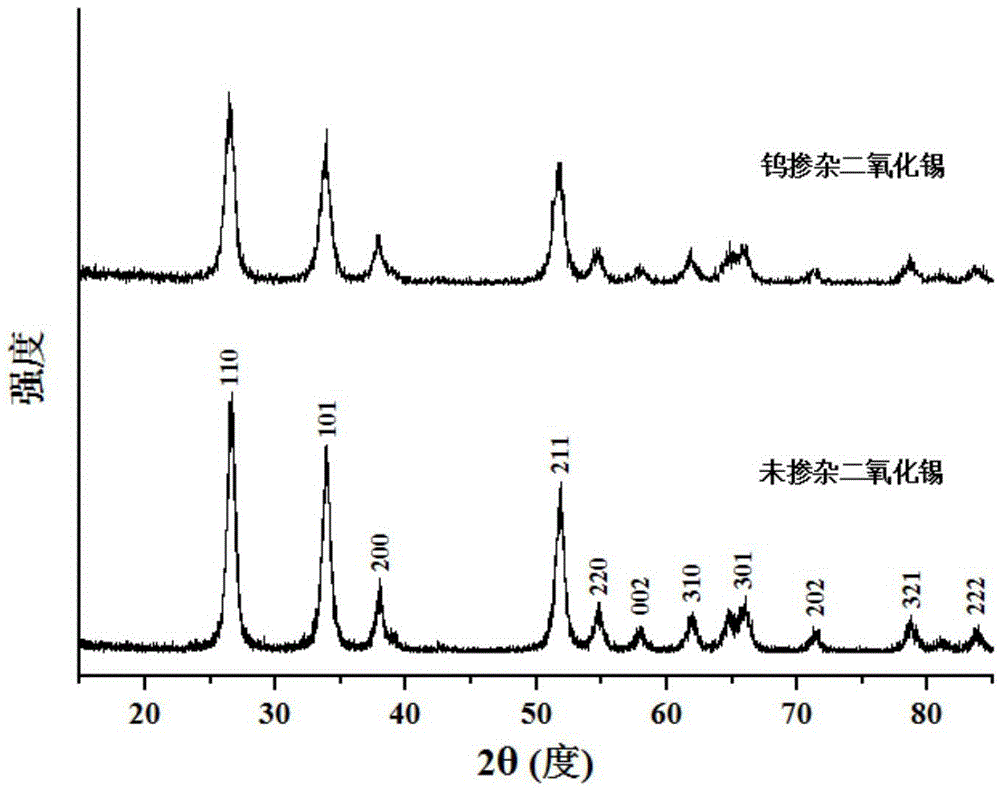

Tungsten-doped stannic oxide sol nanocrystalline and preparing method thereof

InactiveCN105540650AProcess raw materials are easy to getSimple processMaterial nanotechnologyTin oxidesSolventTungsten

Owner:PANZHIHUA UNIV

Special glue for corrugated paper board production line and preparation method of special glue

InactiveCN103102836AHigh bonding strengthImprove permeabilityNon-macromolecular adhesive additivesStarch adhesivesProduction linePulp and paper industry

The invention relates to glue and provides special glue for a corrugated paper board production line, and the special glue has the characteristics of high bonding strength, good permeability, high solid content, low cost, short preparation time and does not need to consume lots of manpower and material resources. Meanwhile, the invention further provides a preparation method of the special glue for the corrugated paper board production line. The preparation method comprises the following steps of: counting in parts by weight, filling 1000+ / 5 parts of water in a tank body, sequentially adding 6-7 parts of caustic soda flakes, 700+ / -5 parts of starch and 1.5+ / -0.1 parts of oxidant, and stirring for 28-32 min; adding 800+ / -5 parts of water and 13+ / -0.5 parts of the caustic soda flakes, and quickly stirring until the viscosity of the glue raises to 11-16 seconds after adding the caustic soda flakes; and adding 4-6 parts of borax, carrying out adequate stirring and uniform mixing, controlling a gelatinization point and maintaining the gelatinization point at 52-55 DEG C, and stopping stirring until the viscosity reaches 13-20 seconds, thereby obtaining the glue.

Owner:FUJIAN WENSONG COLOR PRINTING

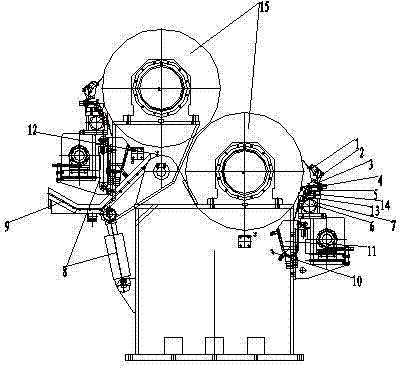

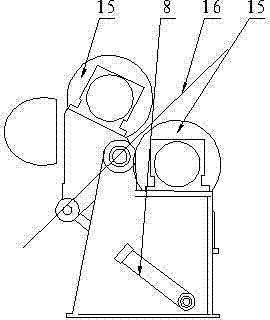

Method for realizing coating for microcapsules by film transfer

The invention discloses a novel method for coating microcapsules, and particularly relates to a method for realizing coating for microcapsules by film transfer. The method disclosed by the invention comprises the following steps of: a, running coating rolls and achieving a running speed, when the tail of paper is led through a coating machine, turning on full-width spraying water, driving an acting combined beam by a cylinder, rotating a metering rod, pressurizing by a loading air pocket, and charging a microcapsule coating by a charge tube; b, when a loading pressure is stable and coating layers on the surfaces of the rolls are uniform, and turning on edge-spraying water; and c, after paper is spread with a full width on the coating machine, bonding the two coating rolls, turning on the full-width spraying water to an automatic position, and adjusting a coating weight according to a coating weight horizontal curve, and via the adjustment of a fine adjustment mechanism and the pressurization of the loading air pocket. The method disclosed by the invention has the advantages that control on the coating weight is stable; the coating weight is convenient and fast to adjust by the fine adjustment mechanism; and a coating solid content is high, so that a requirement on the drying capacity after coating is low, thus reducing steam consumption, and the production cost of per ton of paper.

Owner:HENAN JIANGHE PAPER +1

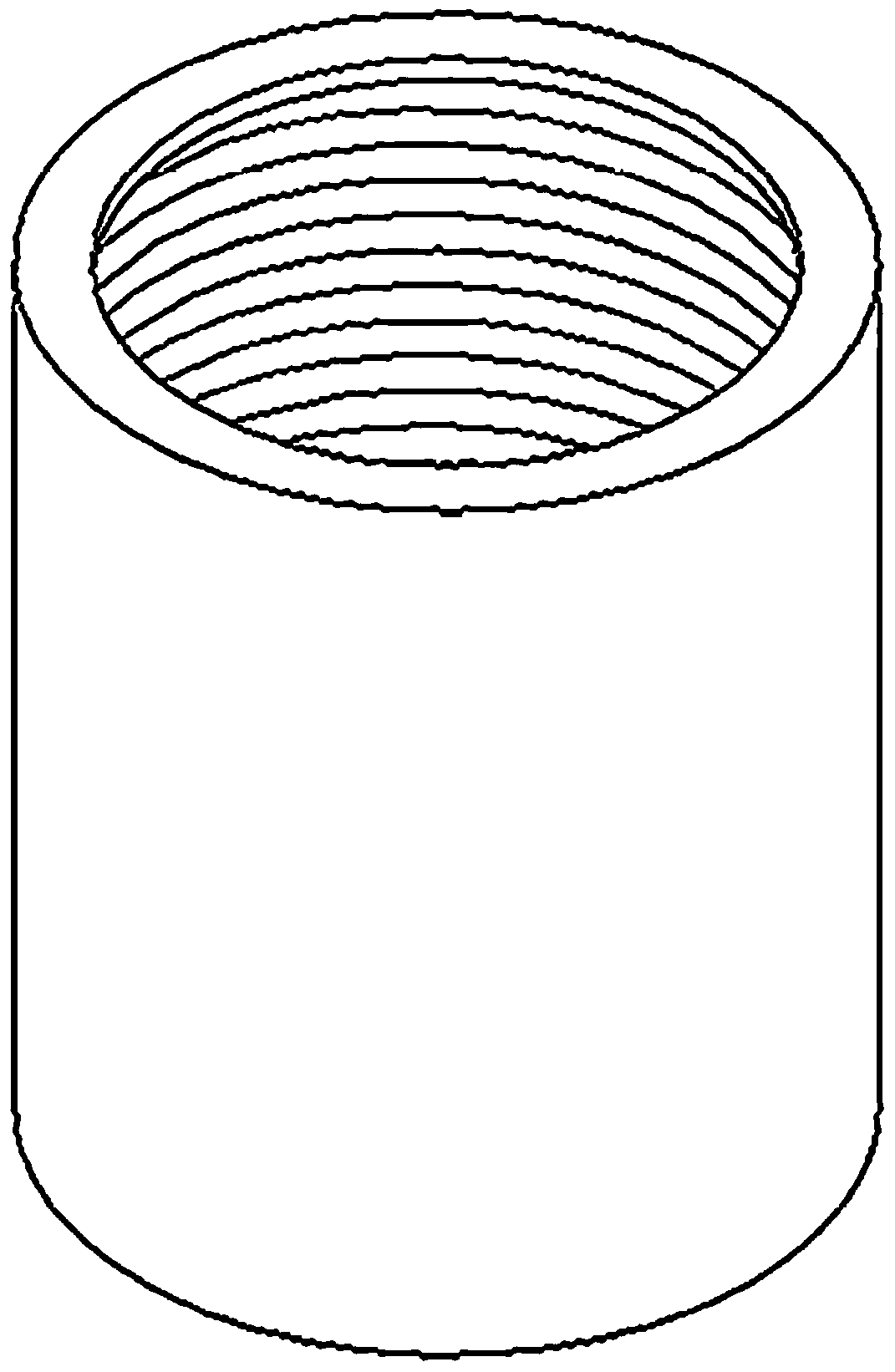

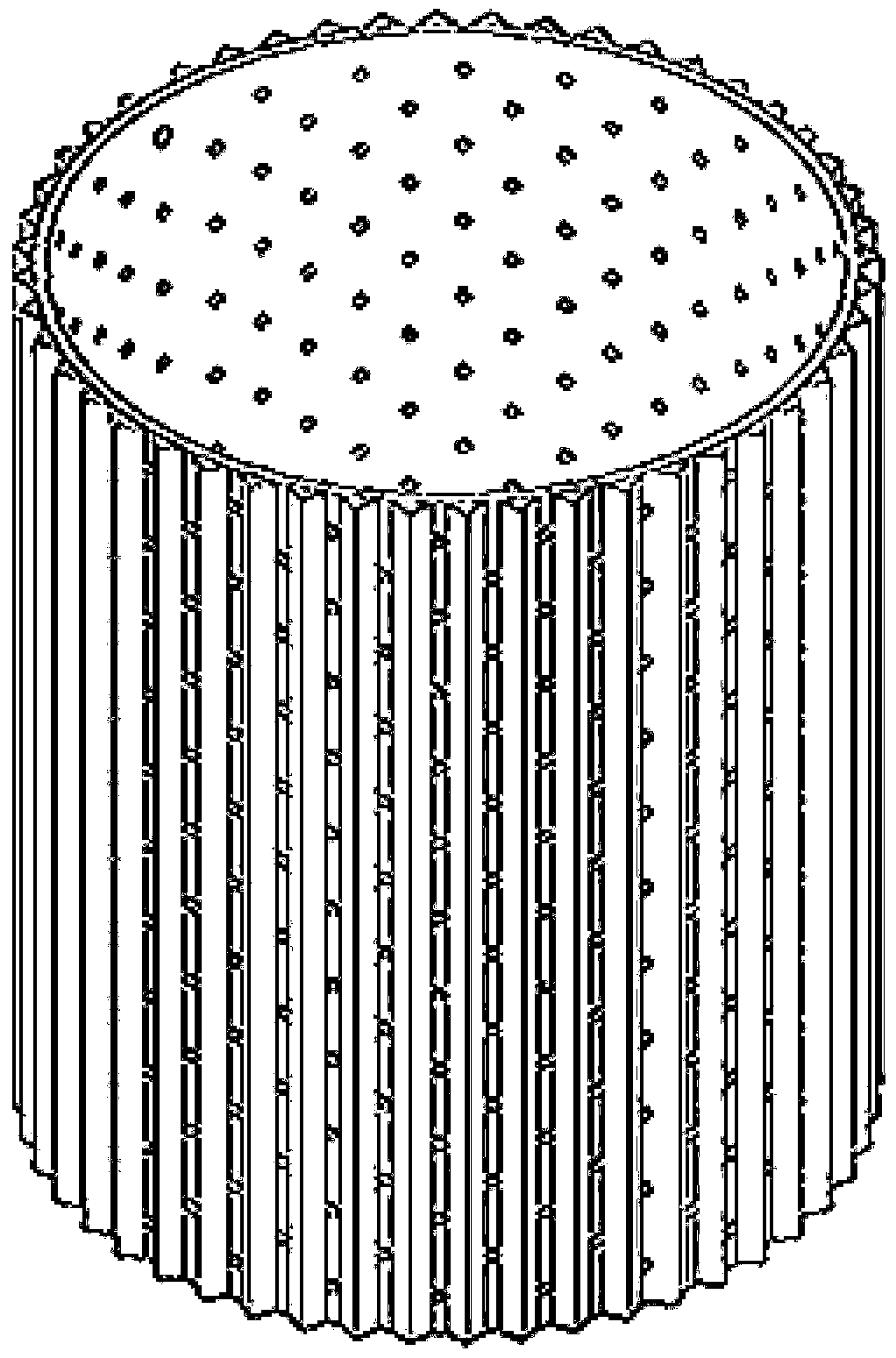

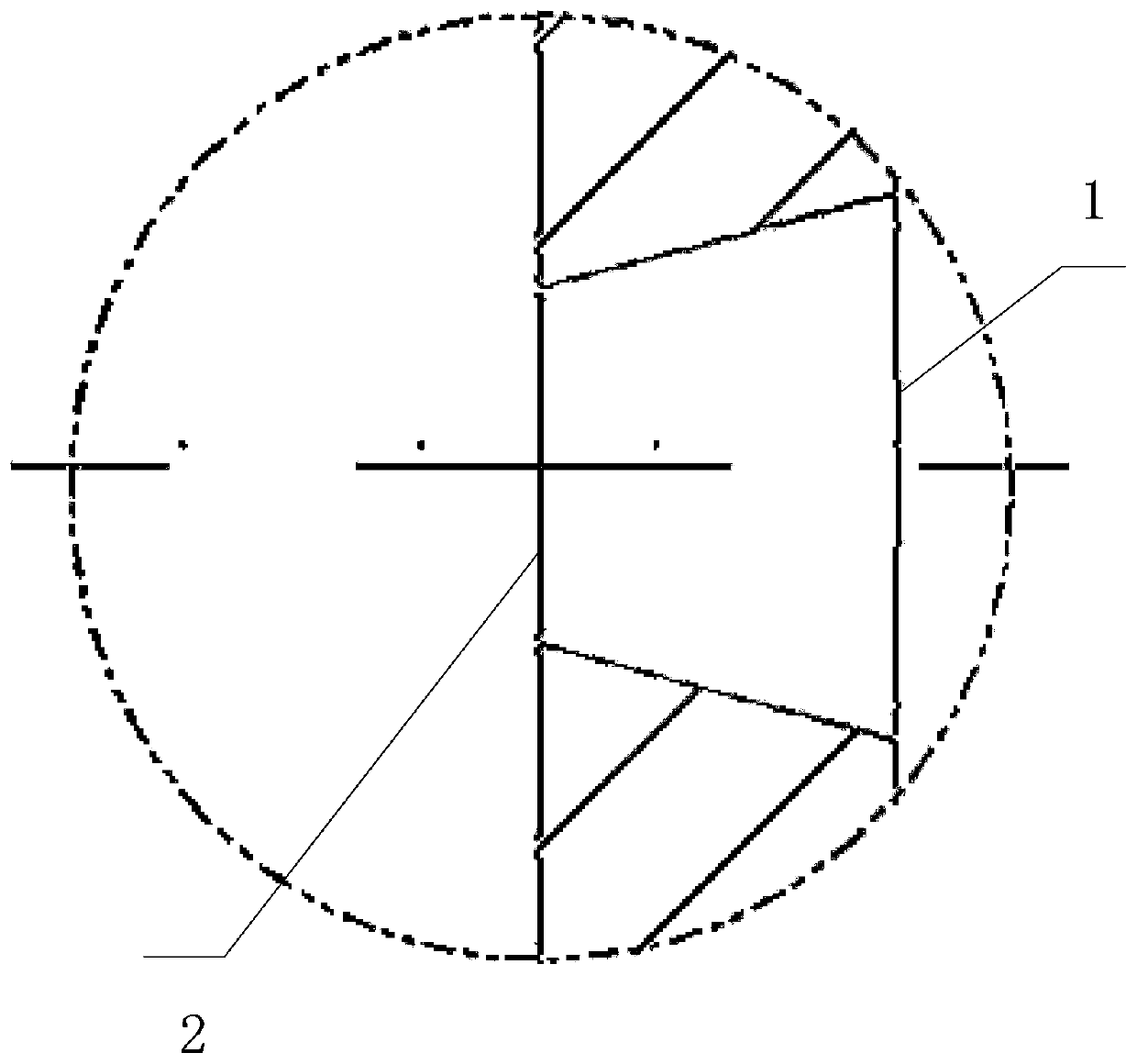

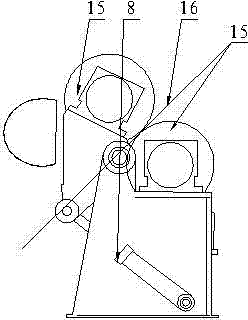

High speed dispersing equipment, slurry, battery pole piece and lithium ion battery

ActiveCN105170002AGood dispersionInhibition of agglomerationRotating receptacle mixersTransportation and packagingElectrical batteryPole piece

The invention belongs to the technical field of slurry preparation and battery preparation, particularly relates to high speed dispersing equipment, slurry, a battery pole piece and a lithium ion battery. The high speed dispersing equipment comprises a dispersing barrel and a dispersing wheel which are coaxially arranged, wherein the dispersing wheel is positioned in the dispersing barrel; the dispersing barrel comprises a side wall provided with a spiral track, and the spiral track is positioned on the inner surface of the side wall; the dispersing wheel comprises a barrel and holes, a plurality of tooth-like bumps are formed on the outer surface of the wall of the barrel, and the holes are of frustum structure and are arranged in the barrel wall. The dispersing capacity of the equipment for the slurry can be effectively improved as a result of the design. Inner substances of the slurry prepared by using the equipment are more uniformly dispersed, so that the agglomeration phenomenon of the active substances is remarkably mitigated. The battery pole piece prepared by using the slurry has smaller impedance, so that the electric property of the lithium ion battery prepared by using the slurry or the electrode pole piece is obviously improved.

Owner:DALIAN CBAK POWER BATTERY CO LTD

Method for preparing Ba1-xSrxTiO3-MgO ferroelectric ceramic blank

The invention discloses a method for preparing a Ba1-xSrxTiO3-MgO ferroelectric ceramic blank, and belongs to the field of inorganic nonmetallic materials. The method comprises the following steps of: preparing materials; preparing premix solution; mixing the materials and the premix solution and performing ball-milling; degassing and adding a catalyst into the mixture; adding initiator into the mixture; performing gel-casting; and demolding and drying. In the method, the Ba1-xSrxTiO3-MgO ferroelectric ceramic blank is prepared by adopting a semi-aqueous gel-casting process which uses deionized water and alcohol organic matters which are soluble with water as solvents, so that the problems that in the conventional dry press method, the ceramic blank with complex shapes and large sizes cannot be prepared, and particularly uniformity inside ceramic parts cannot be ensured are overcome. Meanwhile, the Ba1-xSrxTiO3-MgO ferroelectric ceramic blank prepared by the method has high strength and high plasticity, can be subjected to subsequent processing of machining, isostatic pressing and the like, contributes to preparing ceramics with complex shapes and high compactness, and is suitable for industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method and application method of foamed type waterborne polyurethane

The invention discloses a preparation method and an application method of foaming type waterborne polyurethane. The preparation method comprises the following steps: adding fatty acid, triethylamine and polymer glycol into a reaction kettle, performing reaction for 30-35 minutes at 80-95 DEG C, dehydrating, adding diisocyanate, performing reaction for 2-2.5 hours at 80-85 DEG C, further adding DMPA (Dimethylol Propionic Acid) and 1,4-butanediol, performing reaction for 1.5-2 hours at 80-85 DEG C, and cooling to 40-45 DEG C; and finally, adding a deionized water solution containing a chain expanding agent and an emulsifier, and performing reaction for 1-1.5 hours at 40-45 DEG C, thereby obtaining foaming type waterborne polyurethane. The foamed type waterborne polyurethane disclosed by the invention has a good foaming function, is free of solvent in the synthesis process, and can be applied to production of products such as waterborne polyurethane synthetic leather foamed bases, waterborne polyurethane coating cloth and waterborne polyurethane foamed films, and the problems of solvent pollution and solvent residues caused by application of solvent type polyurethane in production can be solved.

Owner:聊城市鑫润达塑胶制品有限公司

Modified pyridine styrene butadiene rubber latex and synthesis method and application thereof

The invention provides modified pyridine styrene butadiene rubber latex and a synthesis method and application thereof. The modified pyridine styrene butadiene rubber latex is prepared from the following raw materials in percentage by weight: an initiator, an emulsifying agent, a dispersing agent, water and mixed monomers, wherein the dosage of the initiator is 0.2 to 0.6 percent of the weight ofthe mixed monomers; the dosage of the emulsifying agent is 1 to 2 percent of the weight of the mixed monomers; the dosage of the dispersing agent is 2 to 4 percent of the weight of the mixed monomers;the dosage of the water is 95 to 105 percent of the weight of the mixed monomer; and the mixed monomers comprise the following components in percentage by weight: 10 to 85 percent of isoprene, 0 to 50 percent of butadiene, 3 to 15 percent of acrylic ester, 2 to 5 percent of acrylic acid and 10 to 20 percent of monoolefine. The modified pyridine styrene butadiene rubber latex has high solid content, uniform latex particles and low content of residual dialkene, is nontoxic and odorless, and has simple, convenient and safe operations in production and use, good film forming property and good adhesiveness to porous materials and polymer calcic-plastic composite materials; in addition, the chemical stability, the heat resistance and the cold resistance of the modified pyridine styrene butadiene rubber latex are all superior to the conventional pyridine styrene butadiene rubber latex.

Owner:SHANDONG HEYI GAS CO LTD DONGYING CITY

Nano-aluminium oxide paste composition and its preparation method

InactiveCN1242001CGood monodispersityImprove efficiencyPigment treatment with macromolecular organic compoundsNano al2o3Slurry

A nano alumina slurry composition for ceramics, paint, ink, etc is prepared from nano alumina (150 nm), high-molecular disperser, and solvent through sequentially and proportionally adding said disperser and alumina to solvent, high-speed dispersing at 400-3000 rpm for 10-60 min, and grinding for 20 min-24 hr. Its advantages are high content of solid, low viscosity and high stability.

Owner:中科纳米涂料技术(苏州)有限公司

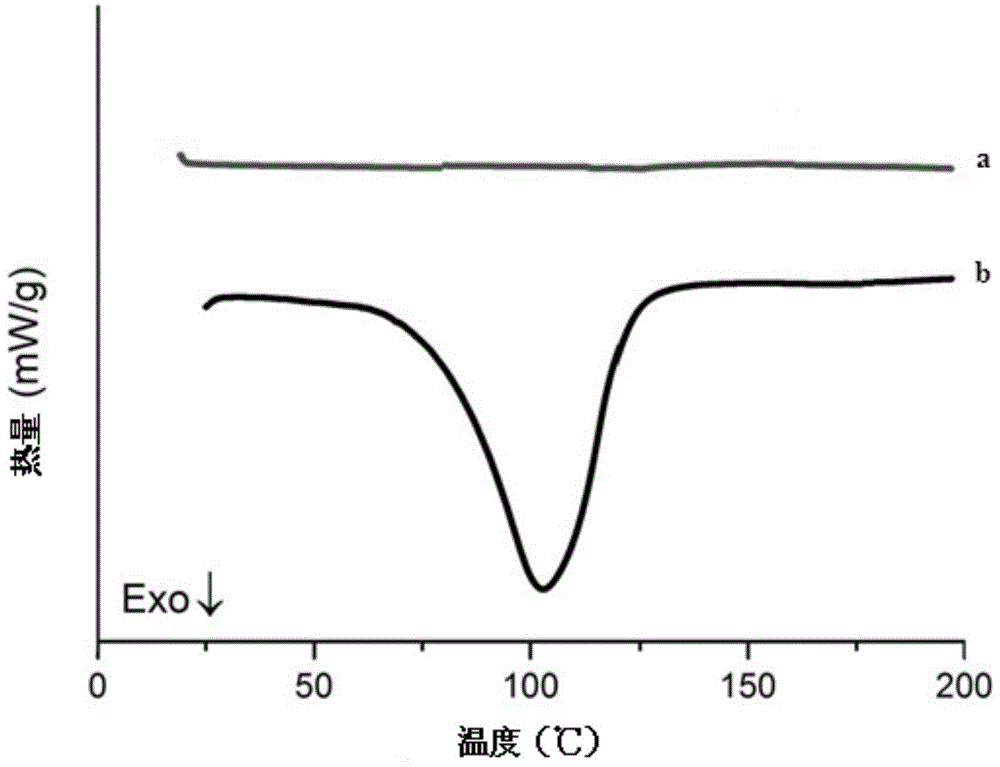

Preparation method of waterproof grade soybean protein adhesive

ActiveCN104497965BImprove water resistanceImprove cross-linking efficiencyProtein adhesivesGlue/gelatin preparationAdhesivePolyamide

The invention provides a waterproof-level soy protein adhesive and a preparation method thereof and relates to an adhesive and a preparation method thereof, in particular to a modified soyabean protein adhesive for waterproof-level plywood. The waterproof-level soy protein adhesive aims at solving the technical problem that an existing adhesive for plywood is not waterproof. The preparation method comprises the steps of beam flour acid heat treatment, beam flour liquidation, polyamide solution synthesis and adhesive modulation. Degreased beam flour or soya bean meal left after soybean oil expelling is used as a main raw material, the water resisting property of the beam flour and the solid content of the soy protein adhesive are improved through acid heat treatment, the cross-linking efficiency, cementing effect and process usability of the soy protein adhesive are improved through liquidation, the water resisting property of the soy protein adhesive is improved through cross-linking of polyamide polyamine resin, and finally the soy protein adhesive high in beam flour content, low in viscosity, long in working life and good in water resisting property and used for the waterproof-level plywood is prepared. The waterproof-level soy protein adhesive and the preparation method belong to the field of adhesive preparation.

Owner:浙江蓝歌新材料科技有限公司

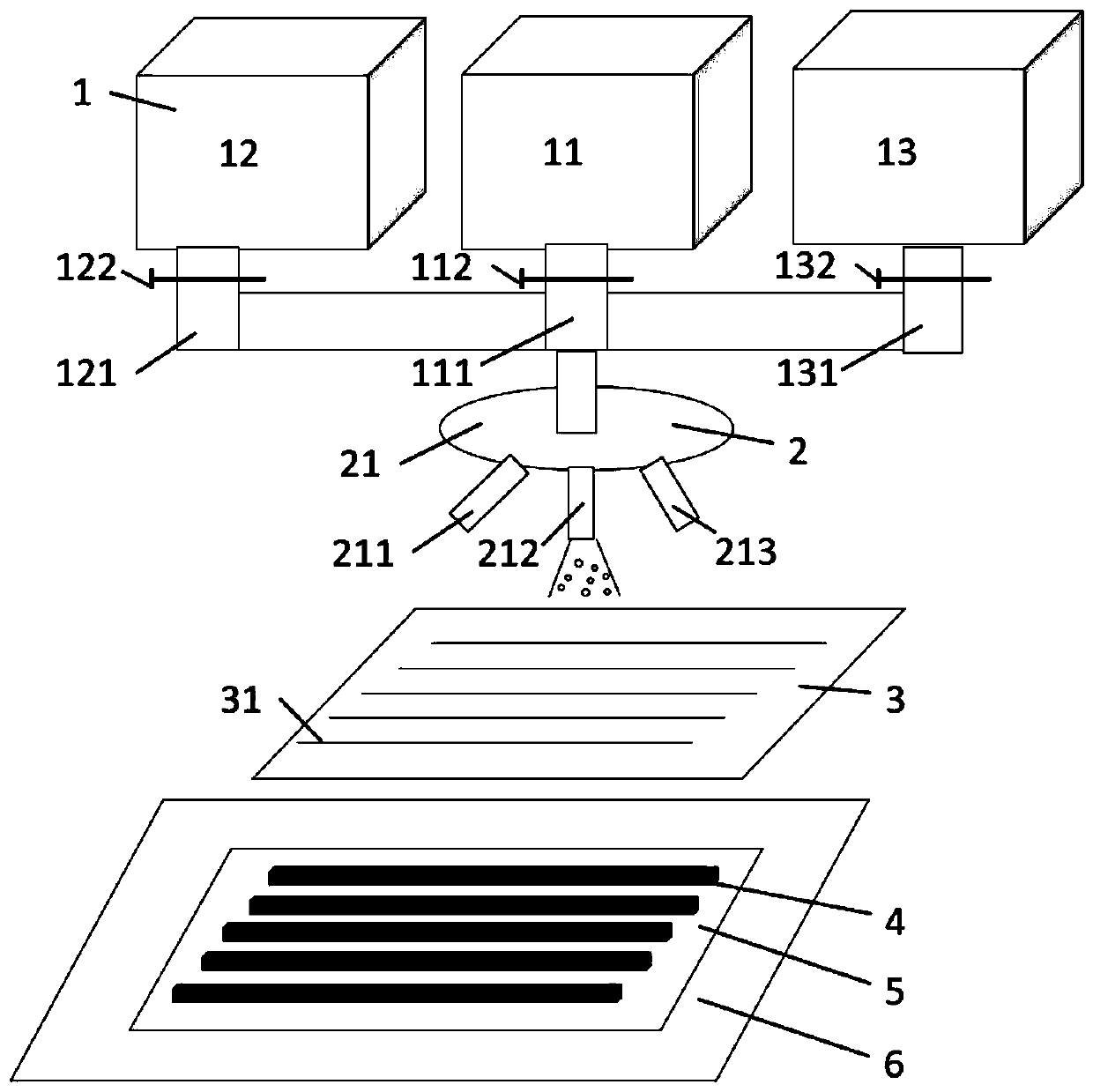

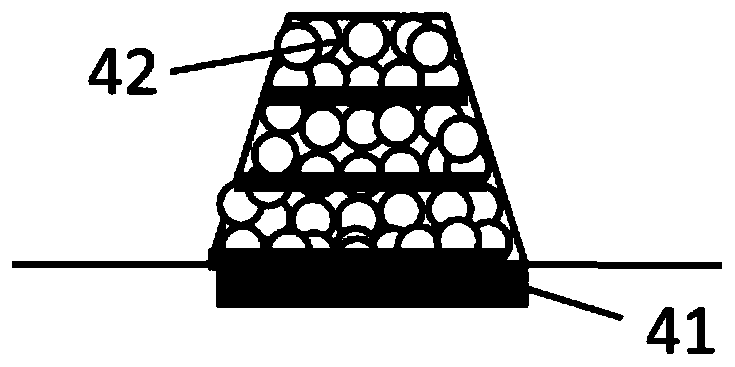

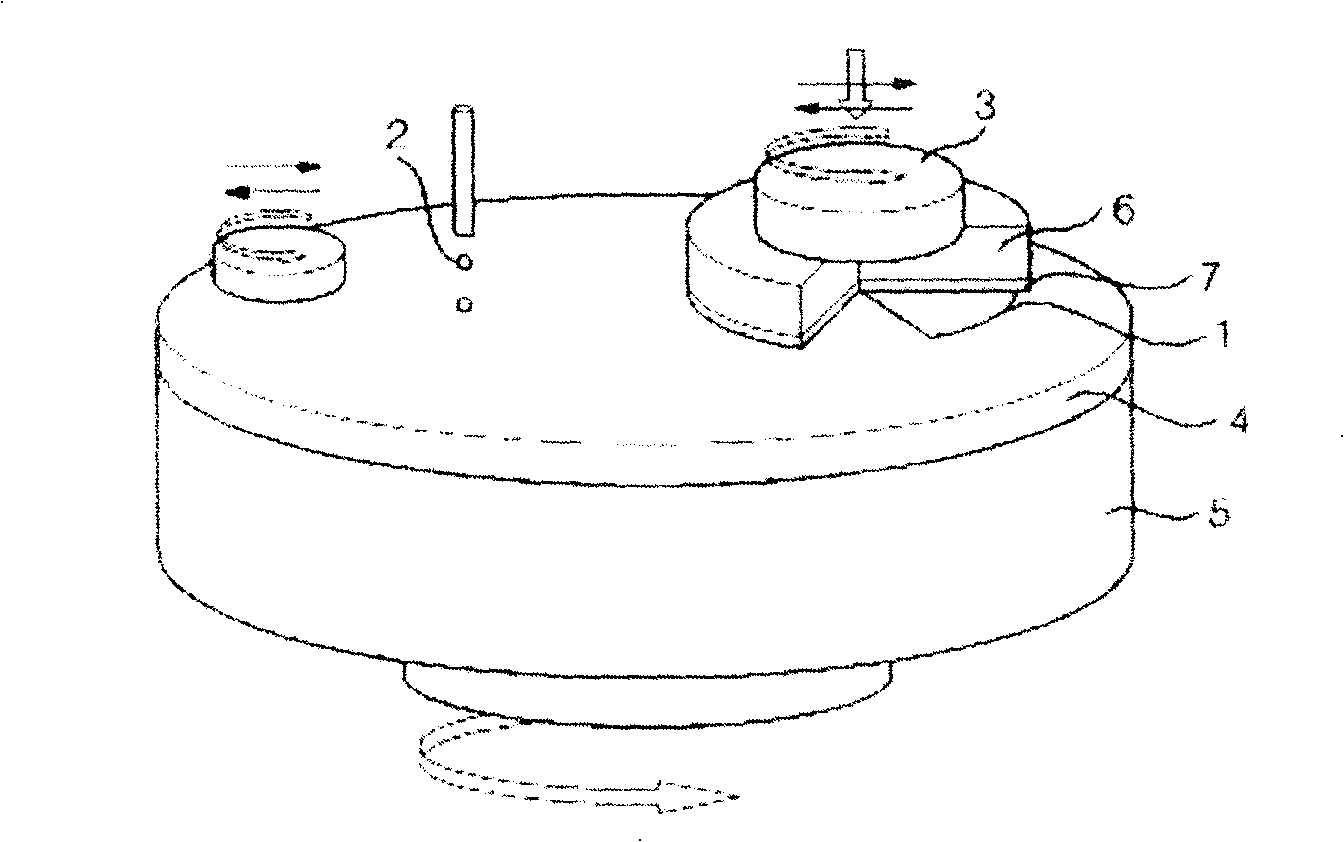

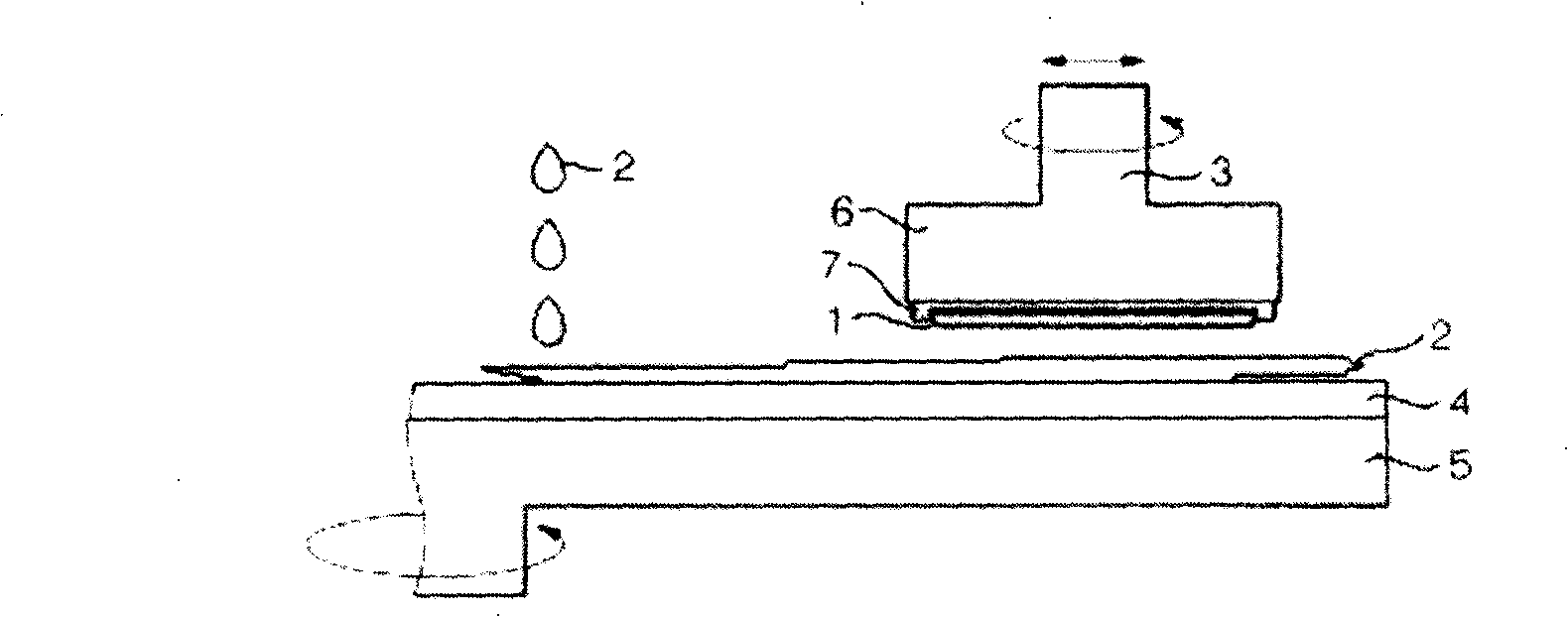

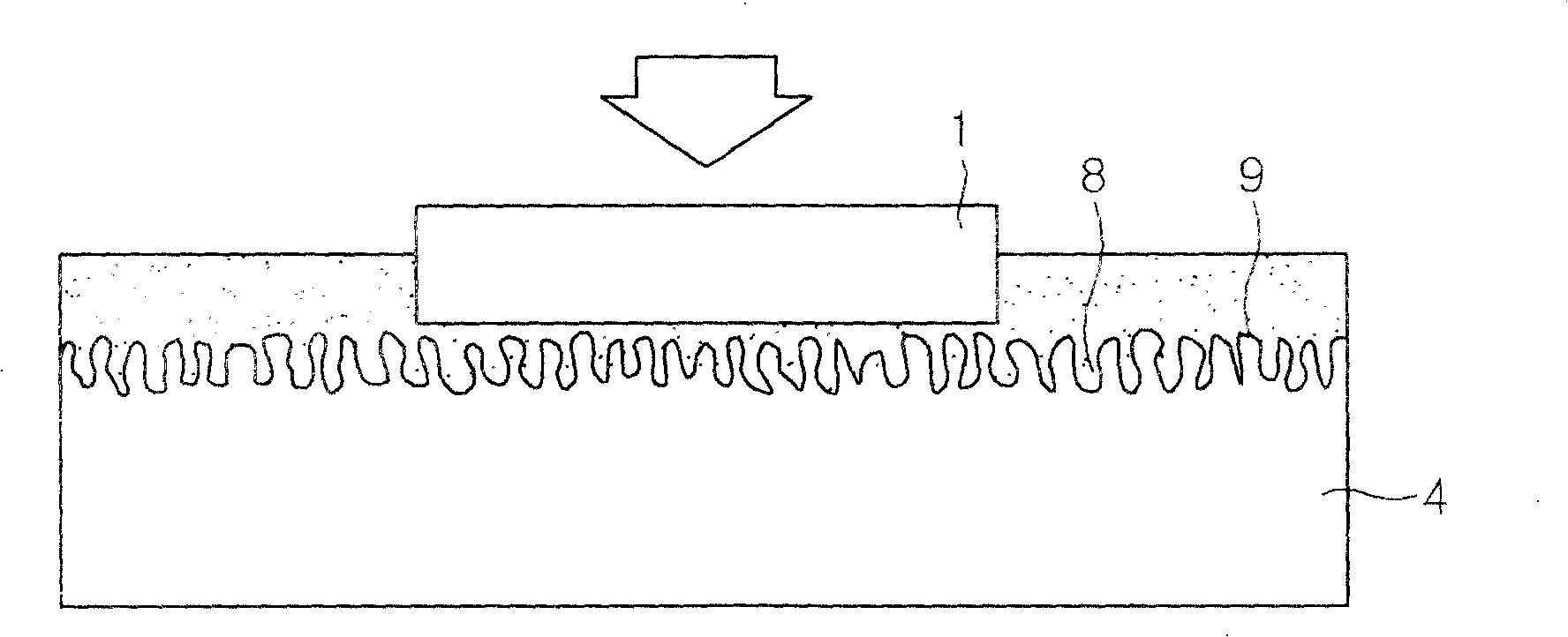

Spraying system for preparing ultra-efficient solar cell electrode, and application of spraying system

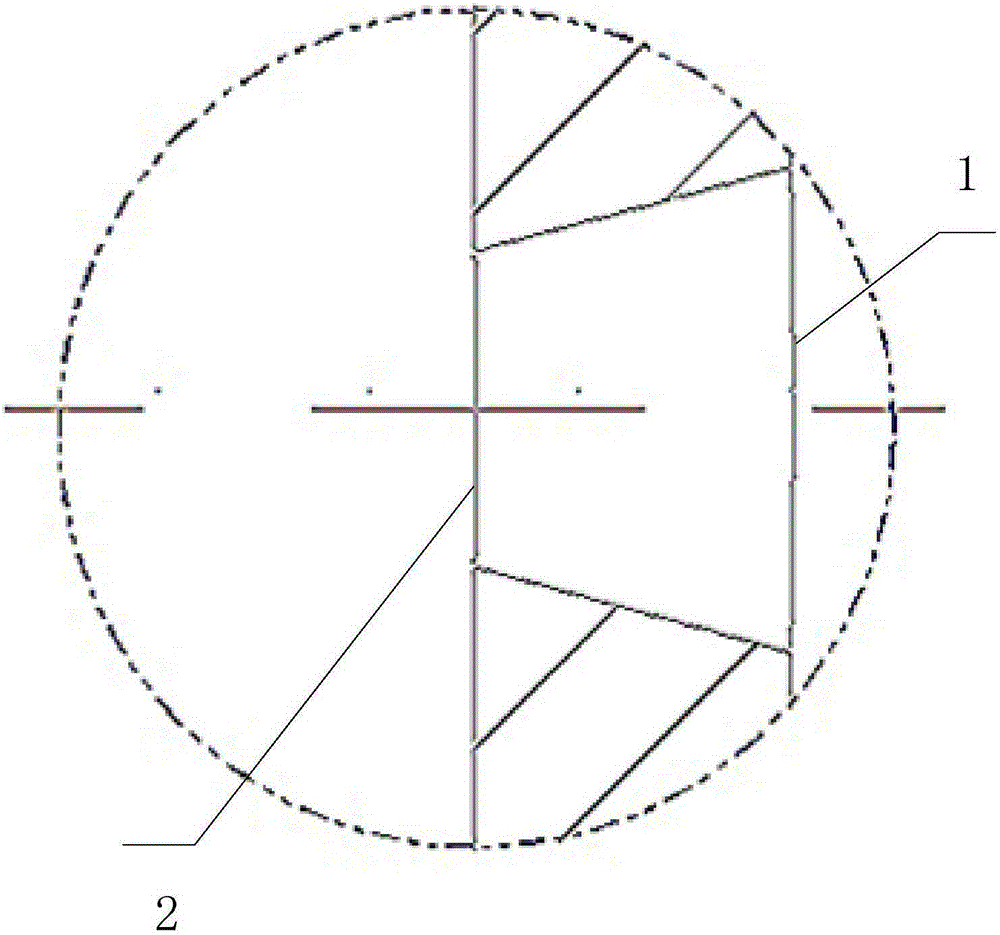

PendingCN111509085AImprove compactnessLine optimizationFinal product manufactureDuplicating/marking methodsElectrical batteryEngineering

The invention relates to a spraying system for preparing a super-efficient solar cell electrode, and application thereof. The system comprises a slurry storage device (1), a spraying device (2) and amask (3), wherein the slurry storage device (1) and the spraying device (2) are connected through a pipeline, and the mask (3) is arranged between the spraying device (2) and a solar cell electrode. The system is characterized in that (1) fully mixing slurry; (2) manufacturing a seed layer; (3) manufacturing a conductive transmission layer; and (4) carrying out a co-firing process, wherein after agrid line (4) is manufactured, an electrode is heated and sintered so as to form the super-efficient solar cell electrode. Compared with the prior art, the manufactured multilayer electrode of the invention is good in electrode compactness and good in grid line electrode stacking leveling property, current transmission is facilitated, the precious metal consumption is reduced, the cost is greatlysaved, and the operation yield is increased.

Owner:西安宏星电子浆料科技股份有限公司

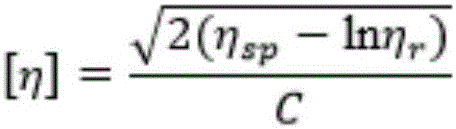

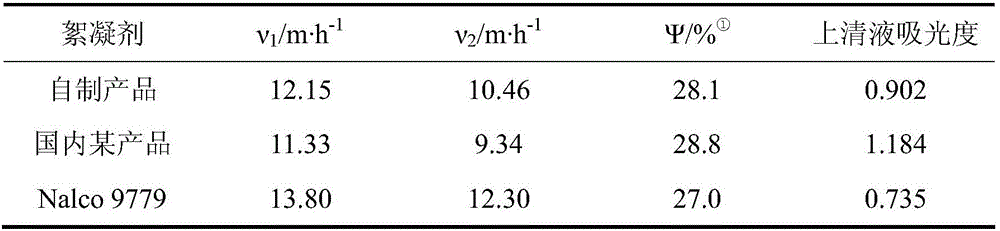

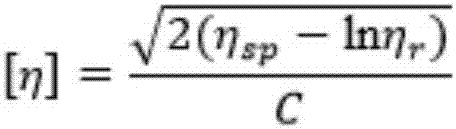

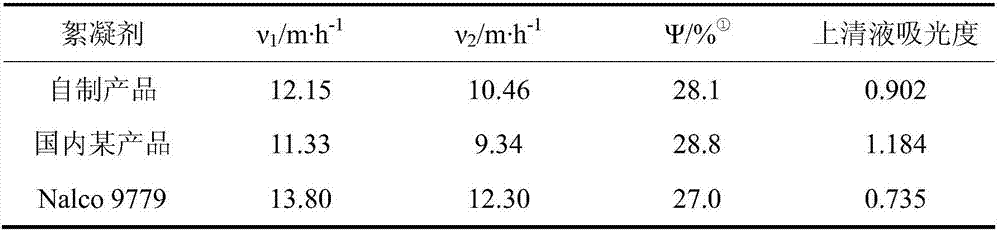

Method for synthesizing flocculating agent with high solid content and high molecular weight based on inverse emulsion

ActiveCN105801733AImprove stabilityGood solid contentWater/sewage treatment by flocculation/precipitationPolymer scienceRed mud

The invention discloses a method for synthesizing a flocculating agent with the high solid content and high molecular weight based on inversion emulsion.The method comprises the steps that a compound emulsifier composed of a Gemini-type emulsifier and a traditional surface active agent is dissolved into an oil phase, a water phase containing an alkene flocculating agent monomer is slowly added into the oil phase, stirring and emulsification are performed to obtain a pre-emulsion, a bifunctional initiating system is added into the pre-emulsion to initiate a polymerization reaction, and emulsion is obtained after the polymerization reaction is completed.The obtained flocculating agent emulsion is high in solid content, large in intrinsic viscosity, good in stability and capable of being widely applied to red mud separation in aluminum oxide production.

Owner:CENT SOUTH UNIV

Colorful coating for paper used for fruit raising pouch and preparation method thereof

The invention discloses a colorful coating for paper used for a fruit raising pouch and a preparation method thereof. The colorful coating comprises the following raw materials by weight: 15 to 22 parts of a pigment, 35 to 45 parts of a waterborne film-forming substance, 5 to 10 parts of an antifoaming agent, 4 to 12 parts of a dispersant, 1 to 5 parts of an antiseptic, 2 to 8 parts of a water repellent agent, 5 to 16 parts of an adhesive and 28 to 39 parts of water. The preparation method comprises the following steps: mixing the pigment, the antifoaming agent, the dispersant and water under stirring at 40 to 45 DEG C for 1 to 2 h; then heating the obtained mixture to 55 to 58 DEG C; successively adding the antiseptic, the water repellent agent and the adhesive and continuing stirring for 0.5 to 0.7 h; cooling the obtained mixture to 25 to 30 DEG C; and adding the waterborne film-forming substance and carrying out stirring for 0.3 to 0.6 h so as to obtain the colorful coating. When applied on the fruit raising pouch, the colorful coating has water resistance, wet-rub resistance and good weatherability, can withstand changes of natural environments in summer, e.g., wind, sunshine and rain, has variable and stable colors, good adhesion and no toxicity and harm and benefits growth of fruit; and the preparation method is simple and has low cost.

Owner:HANGZHOU DIANZI UNIV

Orally taken granule for treating malaria and preparation method thereof

InactiveCN106309406ALow complianceSweet tasteOrganic active ingredientsPharmaceutical non-active ingredientsDocument preparationSucrose

The invention discloses an orally taken granule for treating malaria and a preparation method thereof. The orally taken granule contains artesunate, coating material, stabilizer, filler, preservative and corrigent. 1000mg of oral liquid contains 60g of artesunate, 5g of coating material, 0.35g of stabilizer, 550g of filler, 1.2g of preservative and 5g of corrigent. The orally taken granule can overcome the shortage of infant medicines and can meet the requirement of infant for taste; plenty of documents and practices prove that the medicinal saccharose is taken as main filler, and meanwhile, the covering function of different coating materials for the bitter and the guiding functions of acesulfame and natural plant essence for gustation are surveyed, and the optimal tasty formula is screened through plenty of blinding data model researches.

Owner:FRONT PHARM PLC

Raw material mixing method in lithium manganate material wet production technology

InactiveCN102344167AReduce the amount addedEvenly dispersedManganates/permanganatesHigh energyManganate

The invention discloses a raw material mixing method used in a lithium manganate material wet production technology. The method comprises steps of ball-milling with added water, spray-drying, mixing and sintering. In the step of ball-milling with added water, an electrolyte or a solution thereof is added in, wherein the weight of the added electrolyte or the solution thereof is 0.05 to 2% of that of an aqueous medium. With the raw material mixing method used in the lithium manganate material wet production technology, defects in prior arts of low solid content, high aqueous medium addition, high viscosity, poor dispersion effect, long mixing time, high energy consumption and high cost can be overcome; and advantages of high solid content, low aqueous medium addition, low viscosity, good dispersion effect, short mixing time, low energy consumption and low cost can be realized.

Owner:WUXI JEWEL POWER & MATERIALS

Preparation method of heat-resistant high-strength agricultural machinery adhesive

InactiveCN112358848AImprove heat stabilityImprove heat resistanceAldehyde/ketone condensation polymer adhesivesMacromolecular adhesive additivesPolyesterAdhesive

The invention relates to the technical field of adhesives, in particular to a preparation method of a heat-resistant high-strength agricultural machine adhesive, which is wide in raw material source,simple and convenient in preparation method and excellent in thermal performance, and utilizes modified polyesterimide and modified vinyl ester resin to blend, blend and crosslink. The insulating paint can be stored, has low curing temperature, can be used in occasions with high insulation grade such as agricultural machinery repair and maintenance, has good effect in repairing parts with abradedsurfaces, can replace the commonly used electric welding, electroplating and bushing processes to recover the original geometrical shapes and dimensions of the parts, and has the advantages of simpleprocess, low cost, high efficiency and the like. During repairing of agricultural machinery and tools, the repairing agent has the excellent characteristics of convenience in use, wide raw material source, heat resistance, impact resistance and high corrosion resistance, and is suitable for being applied in the range of agricultural machinery.

Owner:安徽宏翔农业机械有限公司

High-speed dispersion equipment, slurry, battery pole pieces and lithium-ion batteries

ActiveCN105170002BExtended stayGood dispersionRotating receptacle mixersCell electrodesElectrical batterySlurry

The invention belongs to the technical field of slurry preparation and battery preparation, and in particular relates to a high-speed dispersion device, a slurry, a battery pole piece, and a lithium ion battery. Among them, the high-speed dispersion equipment includes a coaxially arranged dispersing barrel and a dispersing wheel, and the dispersing wheel is located in the dispersing barrel; the dispersing barrel includes a side wall with a spiral track, and the spiral track is located on the inner surface of the side wall; the dispersing wheel includes a cylinder and an opening , the outer surface of the cylinder wall of the cylinder has a plurality of protrusions with a tooth-like structure, and the opening adopts a frustum structure and is arranged on the cylinder wall. This design can effectively improve the equipment's ability to disperse the slurry. The dispersion of the internal substances of the slurry prepared by the equipment will be more uniform, and the agglomeration phenomenon among the active substances will be obviously reduced. The impedance of the battery pole piece prepared by using the above slurry is smaller, and the electrical performance of the lithium ion battery prepared by using the above slurry or the battery pole piece is obviously improved.

Owner:DALIAN CBAK POWER BATTERY CO LTD

A kind of preparation method and application method of foaming waterborne polyurethane

The invention discloses a preparation method and an application method of foaming type waterborne polyurethane. The preparation method comprises the following steps: adding fatty acid, triethylamine and polymer glycol into a reaction kettle, performing reaction for 30-35 minutes at 80-95 DEG C, dehydrating, adding diisocyanate, performing reaction for 2-2.5 hours at 80-85 DEG C, further adding DMPA (Dimethylol Propionic Acid) and 1,4-butanediol, performing reaction for 1.5-2 hours at 80-85 DEG C, and cooling to 40-45 DEG C; and finally, adding a deionized water solution containing a chain expanding agent and an emulsifier, and performing reaction for 1-1.5 hours at 40-45 DEG C, thereby obtaining foaming type waterborne polyurethane. The foamed type waterborne polyurethane disclosed by the invention has a good foaming function, is free of solvent in the synthesis process, and can be applied to production of products such as waterborne polyurethane synthetic leather foamed bases, waterborne polyurethane coating cloth and waterborne polyurethane foamed films, and the problems of solvent pollution and solvent residues caused by application of solvent type polyurethane in production can be solved.

Owner:聊城市鑫润达塑胶制品有限公司

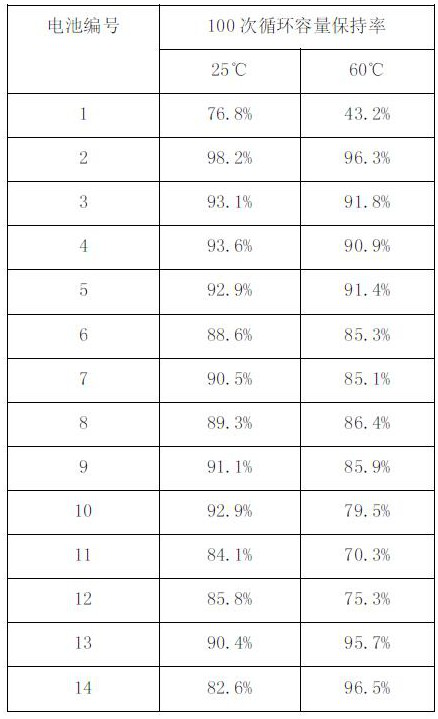

Lithium battery electrolyte additive, electrolyte and lithium battery

ActiveCN112448038AImprove circulation capacityEvenly dispersedSecondary cellsOrganic electrolytesPhysical chemistryUrethane acrylate

The invention belongs to the technical field of batteries, and particularly relates to a lithium battery electrolyte additive, an electrolyte and a lithium battery. The lithium battery electrolyte additive is prepared by the following method: (1) uniformly mixing urethane acrylate and an acrylic monomer; (2) adding paraffin and diatomite into the mixture treated in the step (1), and uniformly mixing; (3) adding 2, 2-dimethoxy-2-phenyl acetophenone and graphite powder into the mixture obtained in the step (2), uniformly mixing, and granulating; (4) adding a lithium halide diatomite graphite mixture into the product treated in the step (3), and uniformly mixing; and (5) curing under ultraviolet irradiation to obtain the lithium battery electrolyte additive. The lithium battery electrolyte additive can significantly improve the cycle capacity retention rate of the battery.

Owner:贵州光瑞新能源科技有限公司

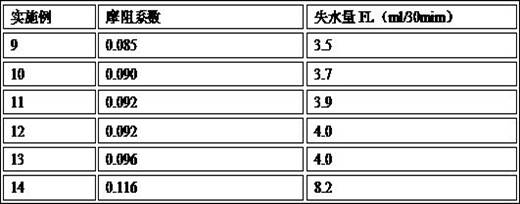

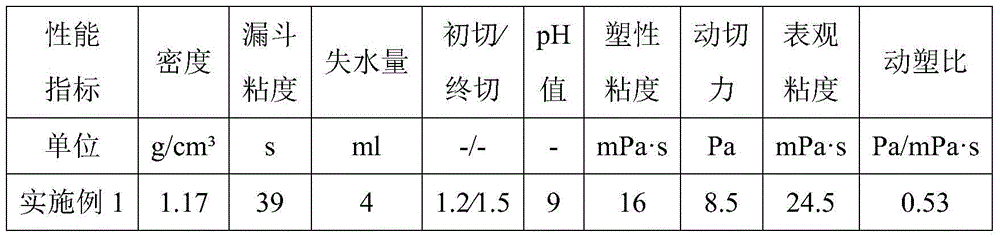

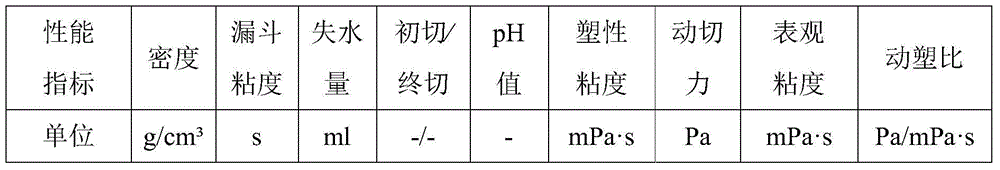

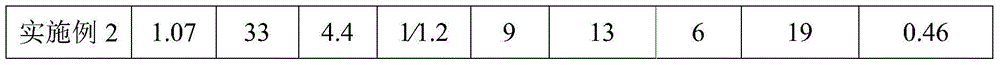

A low-injury water-based drilling fluid suitable for Ecuadorian rainforest and its preparation method

ActiveCN110437811BImprove purification effectAvoid enteringDrilling compositionTemperature controlPreservative

The invention discloses a low-damage water-based drilling fluid suitable for the Ecuadorian rainforest and a preparation method thereof. agent, pH adjuster, soluble salt weighting agent and water, wherein the weight percentage of each component is: thickener 0.2~1.0%, fluid loss reducer 0.4~1.0%, preservative 0.05~0.2%, Acid soluble temporary plugging agent 2.0~4.0%, temperature control lubricant 0.2~0.8%, pH regulator 0.05~0.2%, soluble salt weighting agent 1.0~3.0%, water to make up the balance. The preparation and maintenance of the water-based drilling fluid system of the present invention are simple, no additional auxiliary equipment is needed, it has the characteristics of low viscosity and high shear, and at the same time it has low water loss, good plugging effect, can effectively protect the reservoir, is easy to store, and can reuse.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-water-resistance leather adhesive

InactiveCN104497952AImprove water resistanceGood emulsion adhesionPolyureas/polyurethane adhesivesPrepolymerButadiene-styrene rubber

The invention discloses a high-water-resistance leather adhesive which is prepared from hydrogenated diphenylmethane diisocyanate, poly-adipic acid-1,4-butanediol ester diol, neopentyl glycol, 2,2-dimethylolpropionic acid, deionized water, triethylamine and carboxyl butadiene styrene rubber. In the formula, the neopentyl glycol with branched chain is adopted to enhance the water resistance. By adding the 2,2-dimethylolpropionic acid, the polyurethane has favorable self-emulsifying effect and favorable emulsion adhesive force. The carboxyl butadiene styrene rubber can interact with the 2,2-dimethylolpropionic acid to enhance the water resistance, binding strength and solid content and endow the adhesive with favorable stability. The prepolymer formed by the preparation process in the method forms a crosslinked structure, thereby further enhancing the water resistance. The adhesive film formed by the prepared water-based polyurethane is soft.

Owner:GUANGDONG FION LEATHER CO LTD

A low-temperature, halogen-free, low-solid-content modified rosin-type flux and preparation method thereof

InactiveCN108817731BGood solid contentSolid content modified rosin type flux has good fluidityWelding/cutting media/materialsSoldering mediaOrganic acidOrganic solvent

The invention relates to a low-temperature, halogen-free, low-solid-content modified rosin-type welding flux. The welding flux is prepared form, by mass, 10-15% of modified rosin, 1-5% of organic acidactivator, 0.35-1% of glycerin, 0.009-1% of benzotriazole, 0.3-1 % of triethanolamine, a surfactant and the balance organic solvent, wherein the surfactant is 0.5-3% of the mass of the organic acid activator. The prepared low-temperature, halogen-free and low-solid-content modified rosin-type welding flux prepared has good fluidity, no precipitation and delamination phenomena, no halogen elements, a small amount of modified rosin, a good spreading rate, good weldability, bright and full welding spots and less residues after welding, little corrosion is caused, and cleaning is not needed; therequirements for environmental protection are met; an operation method is sample, the temperature is moderate, there are less experimental steps, the cost is low, less by-products are generated in a synthesis process and are easy to remove, and the synthesis time is short.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A method for synthesizing high solid content and high molecular weight flocculant based on inverse emulsion

ActiveCN105801733BImprove stabilityGood solid contentWater/sewage treatment by flocculation/precipitationPolymer scienceRed mud

The invention discloses a method for synthesizing a flocculating agent with the high solid content and high molecular weight based on inversion emulsion.The method comprises the steps that a compound emulsifier composed of a Gemini-type emulsifier and a traditional surface active agent is dissolved into an oil phase, a water phase containing an alkene flocculating agent monomer is slowly added into the oil phase, stirring and emulsification are performed to obtain a pre-emulsion, a bifunctional initiating system is added into the pre-emulsion to initiate a polymerization reaction, and emulsion is obtained after the polymerization reaction is completed.The obtained flocculating agent emulsion is high in solid content, large in intrinsic viscosity, good in stability and capable of being widely applied to red mud separation in aluminum oxide production.

Owner:CENT SOUTH UNIV

Method for realizing coating for microcapsules by film transfer

The invention discloses a novel method for coating microcapsules, and particularly relates to a method for realizing coating for microcapsules by film transfer. The method disclosed by the invention comprises the following steps of: a, running coating rolls and achieving a running speed, when the tail of paper is led through a coating machine, turning on full-width spraying water, driving an acting combined beam by a cylinder, rotating a metering rod, pressurizing by a loading air pocket, and charging a microcapsule coating by a charge tube; b, when a loading pressure is stable and coating layers on the surfaces of the rolls are uniform, and turning on edge-spraying water; and c, after paper is spread with a full width on the coating machine, bonding the two coating rolls, turning on the full-width spraying water to an automatic position, and adjusting a coating weight according to a coating weight horizontal curve, and via the adjustment of a fine adjustment mechanism and the pressurization of the loading air pocket. The method disclosed by the invention has the advantages that control on the coating weight is stable; the coating weight is convenient and fast to adjust by the fine adjustment mechanism; and a coating solid content is high, so that a requirement on the drying capacity after coating is low, thus reducing steam consumption, and the production cost of per ton of paper.

Owner:HENAN JIANGHE PAPER +1

A kind of composite brine drilling fluid

The invention discloses a compound brine drilling fluid which comprises the following components in parts by weight: 100 parts of water, 0.12-0.17 parts of sodium hydroxide, 0.15-0.25 parts of polyanionic cellulose, 0- 0.3 parts of carboxymethyl cellulose, 2-5 parts of calcium carbonate, 0.8-1.2 parts of sulfonated tannin, 0.8-1.3 parts of graphite powder, 0-1 part of filtrate reducer A, 0.8-1.2 parts of filtrate reducer B, 2-10 parts of sodium formate, 3-15 parts of sodium chloride and 1.8-2.5 parts of potassium chloride. The composite brine drilling fluid disclosed by the invention has good inhibition effect on water-sensitive minerals in reservoirs and low harm to the permeability of reservoirs, is free of clay phase and low in the content of solid phase and hardly damages stratum. The composite brine drilling fluid has the advantages of good rheology, strong inhibition and lower cost; the site preparation process is simple, operation and maintenance are convenient and the composite brine drilling fluid can be effectively applied to protective drilling operations of low-porosity, low-pressure and low-permeability reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

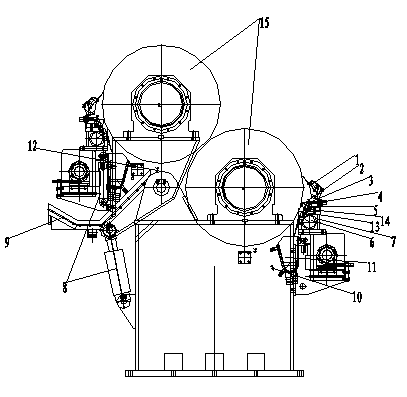

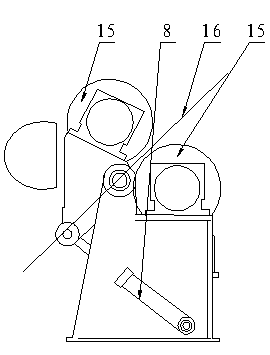

Slurry for cmp and method of polishing substrate using same

ActiveCN100445343CGood solid contentImprove dispersion stabilityOther chemical processesSemiconductor/solid-state device manufacturingDesign standardSlurry

The invention describes a polishing slurry and a preparation method thereof. Specifically, the present invention relates to a slurry for chemical mechanical polishing (hereinafter referred to as 'CMP'). When this polishing slurry is applied to CMP in STI (Shallow Trench Isolation) The polishing rate of the layer has high selectivity. This selectivity is essential for the production of ultra-highly integrated semiconductor silicon wafers (ultra-highly integrated semiconductor silicon wafers have certain design standards for D-RAMs of 256 megabytes or higher, such as a design standard of 0.13 μm or smaller). important. The invention includes a method and equipment for pretreatment of polishing particles, dispersion equipment and its operation method, dosage and addition method of chemical additives and a transfer sample device. The invention can produce high-performance nano-scale ceria slurry, which is very important for the CMP of ultra-highly integrated semiconductors with a thickness of less than or equal to 0.13 μm, especially the STI process.

Owner:K C TECH +1

Nano zircon oxide slurry composition and preparation process thereof

InactiveCN1206287CGood monodispersityImprove efficiencyPigment treatment with macromolecular organic compoundsAdhesive cementPhysical chemistry

The invention relates to a nano-zirconia slurry composition and a preparation method thereof. The composition is composed of 10-75% of nano-zirconia with an average particle diameter of primary particles below 100nm, and 0.4-15% of a polymer dispersant. %, the remainder of the solvent composition; the preparation method is to add the polymer dispersant to the solvent, then add nano-zirconia, disperse with a high-speed disperser at 400-2200rpm for 10-70 minutes, and grind the obtained nano-zirconia slurry for 15 minutes- After 30 hours, the finished product of nano-zirconia slurry is made. The nano zirconia slurry of the present invention is a dispersion system with high solid content and low viscosity, has good monodispersity and high stability, and can be widely used in the fields of ceramics, coatings, inks, textiles, cosmetics, adhesives and the like.

Owner:中科纳米涂料技术(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com