Method for realizing coating for microcapsules by film transfer

A technology of microcapsule and film transfer, applied in the direction of paper, etc., can solve the problem of not being able to use film transfer to coat microcapsules, etc., and achieve the effects of convenient and quick adjustment, reduction of production cost, and reduction of steam consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

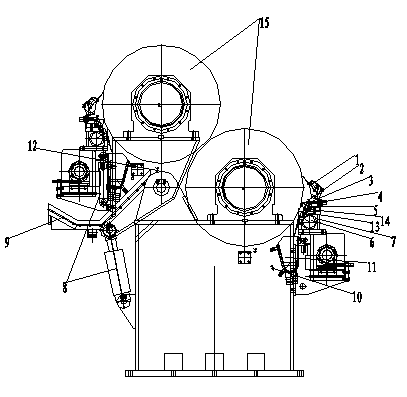

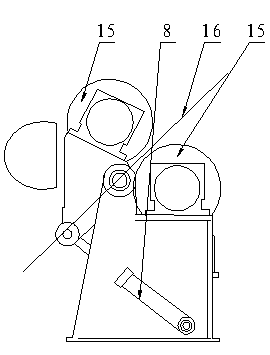

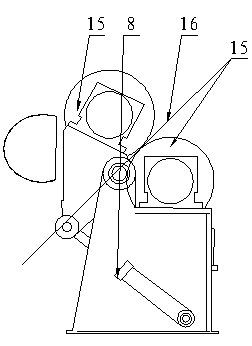

[0015] Film transfer among the present invention realizes the method for coating microcapsules and comprises: a. coating roll 15 runs, and coating roll 15 speeds reach running speed, and when paper tail draws through coater, open full-width spray water 10, cylinder Drive 8 actions to close the beam to make the metering rod 2 and the coating roller 15 fit together, the metering rod 2 rotates, the loading air bag 5 is pressurized to force the feeding pipe 6 to apply microcapsule coating to the roller surface, b. When the feeding pressure is stable and the roller surface When the coating layer is uniform, turn on the side spray water 12 to spray the roller surface, c. After the paper is placed in the full width of the coating machine, the two coating rollers are bonded together, and the full width spray water 10 is hit to the automatic position, d. The cloth amount banner curve is adjusted by the fine-tuning mechanism 4, and the air bag 5 is loaded to pressurize to adjust the coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com