Method for synthesizing flocculating agent with high solid content and high molecular weight based on inverse emulsion

A high molecular weight, inverse emulsion technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of widening molecular weight distribution, poor heat dissipation, crosslinking, etc., and achieve high relative molecular weight and good dimensional stability of polymers , Improve the effect of solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

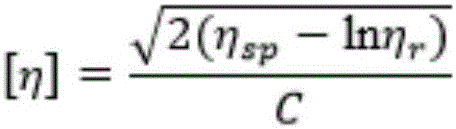

Embodiment 1

[0060] Weigh 35g of 65% ammonium acrylate monomer solution, add 1.37g of 5% EDTA solution and 0.52g of sodium chloride to it to form the water phase. Weigh 10g of the oil phase IsoparM into the reaction kettle, add emulsifiers Hypermer22962.05g, OP-100.95g to it, stir and mix well, slowly drop into the oil phase 30g of water phase and 0.624g of 2.5% bifunctional initiator , stirring vigorously to make it fully emulsified. Nitrogen was blown into the reaction kettle for 30 minutes, and then 0.5 g of 2.5% sodium bisulfite was slowly added dropwise, and the reaction was controlled at 15° C., and the reaction time continued for 6 hours. The emulsion was taken for analysis, the solid content of the emulsion was 42.33%, the intrinsic viscosity reached 1824.65mL / g, and the mechanical and thermal stability of the emulsion were good. Compared with Comparative Example 1 and Example 3, the intrinsic viscosity and solid content of the emulsion are all improved.

Embodiment 2

[0062] Weigh 35g of 65% ammonium acrylate monomer solution, add 1.37g of 5% EDTA solution and 0.52g of sodium chloride to it to form the water phase. Weigh 10g of the oil phase IsoparM into the reaction kettle, add emulsifiers Hypermer22962.05g, OP-100.95g to it, stir and mix well, slowly drop 30g of water phase and 0.5g of 2.5% bifunctional initiator into the oil phase , stirring vigorously to make it fully emulsified. Nitrogen was blown into the reaction kettle for 30 minutes, and then 0.4 g of 2.5% sodium bisulfite was slowly added dropwise, and the reaction was controlled at 15° C., and the reaction time continued for 3 hours. Then the reaction temperature was raised rapidly to 45° C., 0.31 g of 2.5% 2,2-azobisisobutylamidine hydrochloride (V50) was added, and the reaction was carried out at constant temperature for 4 hours. Also take the emulsion for analysis, the solid content of the emulsion is 43.10%, the intrinsic viscosity reaches 1662.02mL / g, and the mechanical sta...

Embodiment 3

[0064] Weigh 20 g of 50% ammonium acrylate solution, 20 g of 50% acrylamide solution, 1.2 g of 5% EDTA solution, and 0.6 g of sodium chloride, and mix the above four to form an aqueous phase. Weigh 10g of the oil phase IsoparM into the reaction kettle, add emulsifiers Hypermer22962.05g, OP-100.95g to it, stir and mix well, slowly drop 30g of water phase and 0.48g of 2.5% bifunctional initiator into the oil phase , stirring vigorously to make it fully emulsified. Nitrogen was blown into the reactor for 30 minutes, and then 0.384 g of 2.5% sodium bisulfite was slowly added dropwise to control the reaction at 15° C., and the reaction time continued for 6 hours. The emulsion was taken for analysis, the solid content of the emulsion was 32.41%, the intrinsic viscosity reached 1722.74mL / g, and the mechanical and thermal stability of the emulsion were good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com