Slurry for cmp and method of polishing substrate using same

A polishing slurry and substrate technology, applied in the polishing field, can solve the problems of no large particle number analysis, reducing the nitride layer elimination rate, large particle control and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

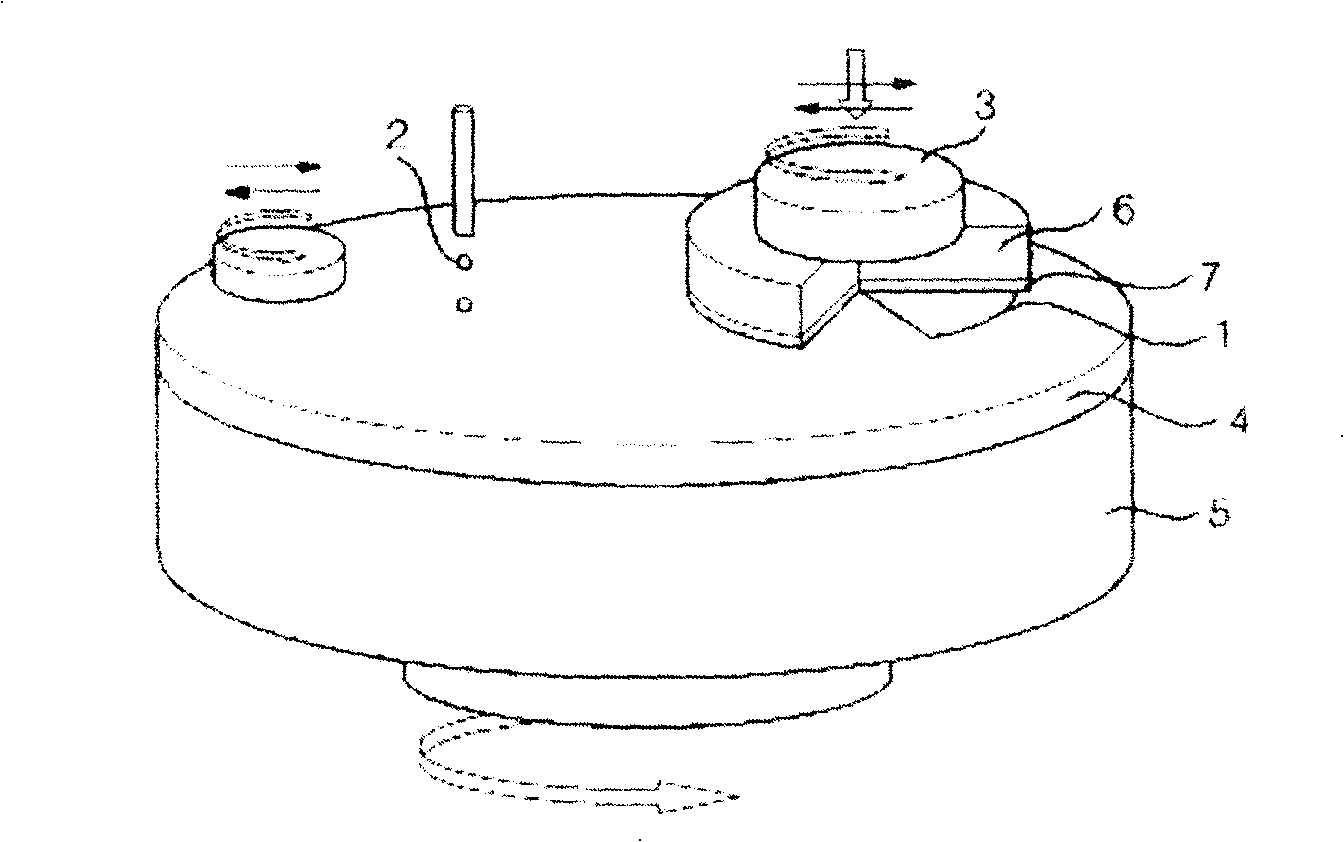

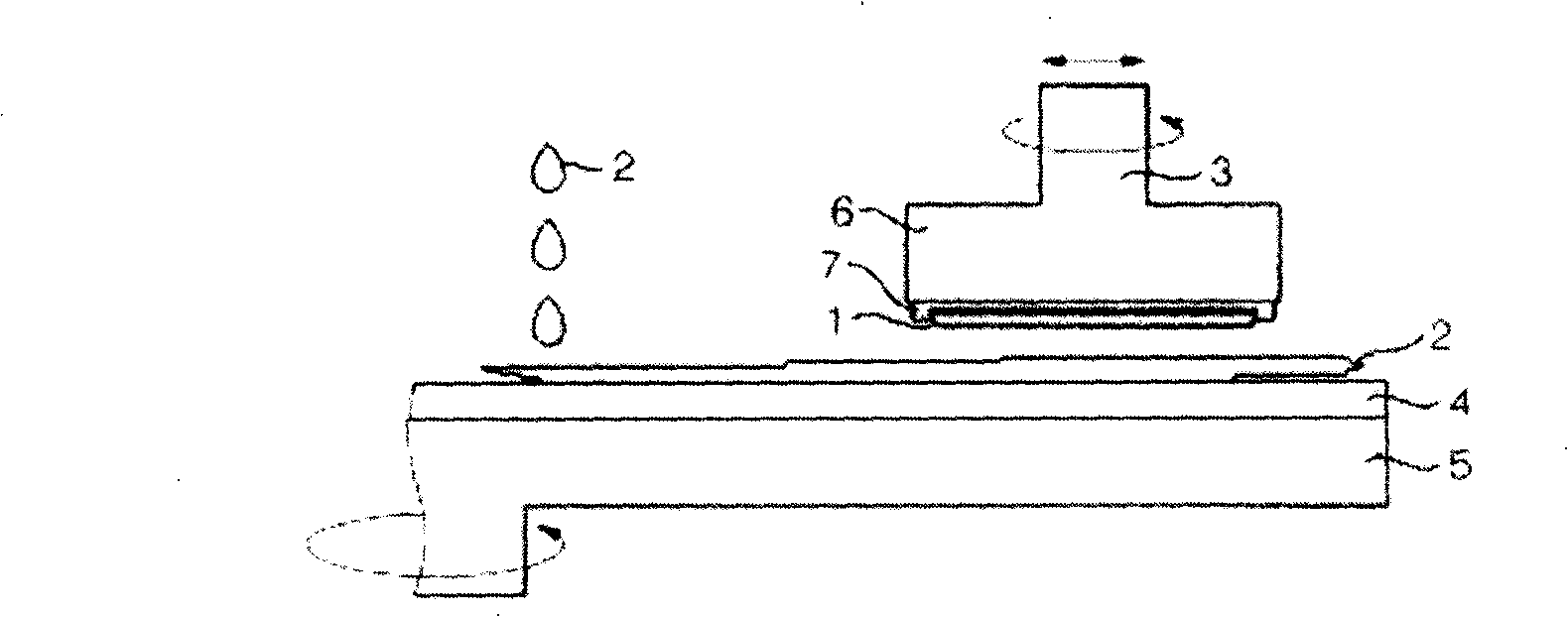

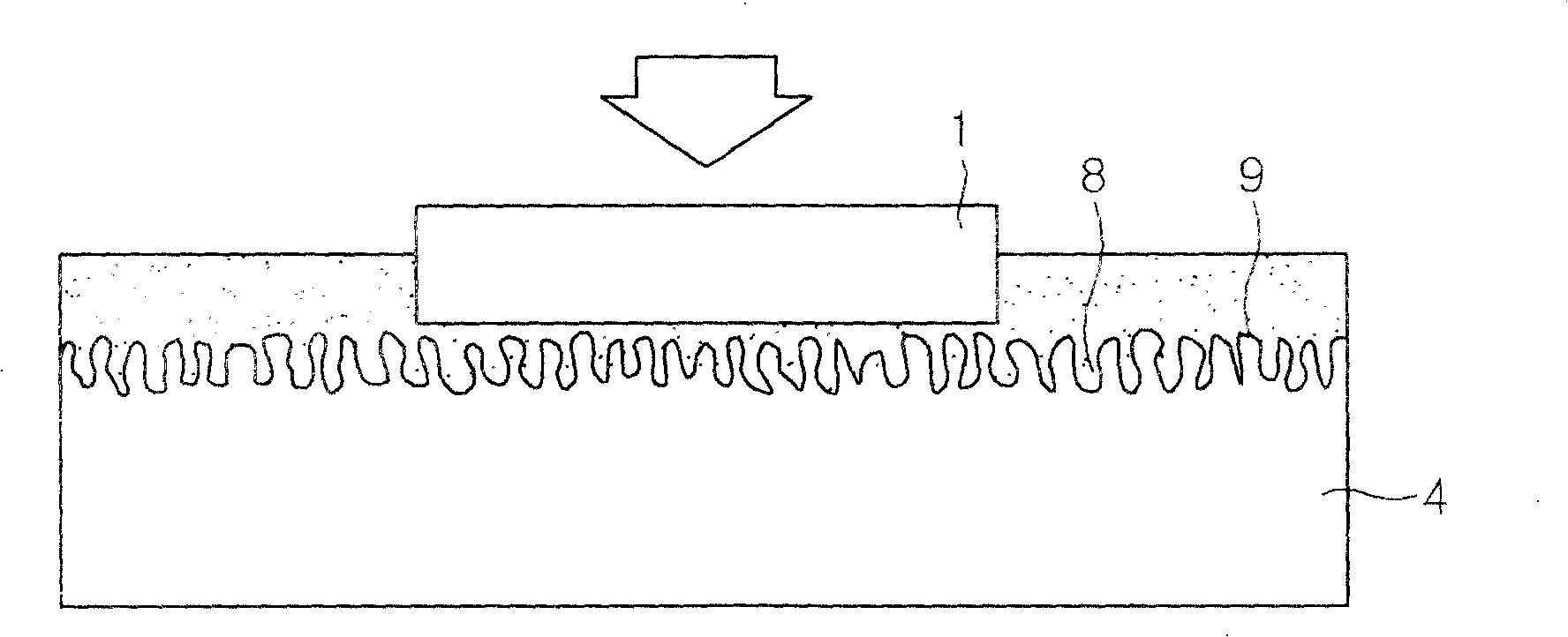

[0028] The preparation method of the polishing slurry in the present invention and the analysis of the properties of the polishing slurry will be described in detail below. In addition, the present invention will also illustrate the preparation method of polishing slurry using cerium oxide as polishing particles, and the method of using deionized water and anionic polymer as dispersant. Finally, this paper will also give the experimental results of the CMP process, that is, how the oxide film polishing rate and selectivity depend on the process conditions. The present invention may require further improvement in the future, and its scope of application is not limited to the scope discussed herein.

[0029] [Preparation method of ceria polishing slurry]

[0030] The ceria polishing slurry of the present invention comprises ceria powder, deionized water, anionic polymer dispersant and an additive such as a weak acid or a weak base. The preparation method of the polishing slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com