A kind of composite brine drilling fluid

A technology of brine drilling fluid and polyanion, which is applied in the field of drilling fluid, can solve the problems of not being able to meet the drilling requirements of normal pressure-low pressure reservoirs, and achieve the effects of easy operation and maintenance, good rheology, and low solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The composite brine drilling fluid of the present embodiment comprises the following components by weight: 100 g of water, 0.15 g of sodium hydroxide, 0.2 g of high-viscosity polyanionic cellulose, 0.3 g of low-viscosity carboxymethyl cellulose, 1 g of sulfonated phenolic resin, Sulfonated tannin extract 1g, superfine calcium carbonate 5g, graphite powder 1g, sodium formate 10g, sodium chloride 15g, potassium chloride 2g.

[0015] The preparation method of the composite brine drilling fluid in this embodiment is as follows: Weigh water, add sodium hydroxide, high-viscosity polyanionic cellulose, low-viscosity carboxymethyl cellulose, sulfonated phenolic resin, and sulfonated tannin extract successively under stirring conditions , superfine calcium carbonate, graphite powder, after mixing evenly, slowly add sodium formate, sodium chloride, potassium chloride under high-speed stirring, after fully stirring evenly, let stand at room temperature for 24h, that is.

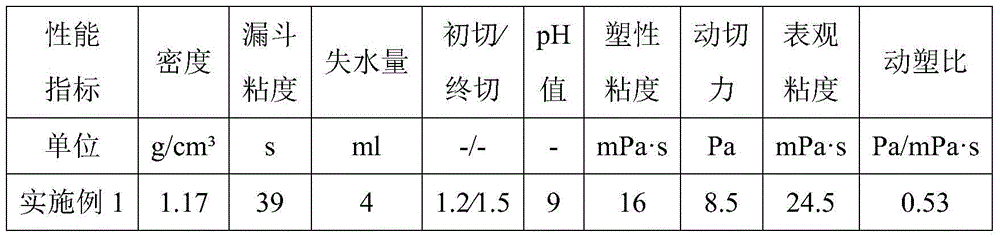

[0016] T...

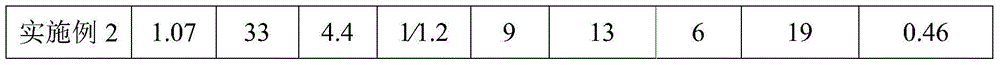

Embodiment 2

[0029] The composite brine drilling fluid of this embodiment comprises the following components by weight: 100 g of water, 0.15 g of sodium hydroxide, 0.2 g of high-viscosity polyanionic cellulose, 1 g of sulfonated phenolic resin, 1 g of sulfonated tannin extract, and ultrafine calcium carbonate 2g, graphite powder 1g, salt-resistant polymer fluid loss reducer (GMP-1, commercially available, purchased from Xinjiang Korla Wanshunda Petroleum Technology Co., Ltd.) 1g, sodium formate 2g, sodium chloride 3g, potassium chloride 2g.

[0030] The preparation method of the composite brine drilling fluid of this embodiment is as follows: Weigh water, add sodium hydroxide, high-viscosity polyanionic cellulose, sulfonated phenolic resin, sulfonated tannin extract, ultrafine calcium carbonate, graphite powder in sequence under stirring conditions , Salt-resistant polymer fluid loss reducer (GMP-1), after mixing evenly, slowly add sodium formate, sodium chloride, potassium chloride under h...

Embodiment 3

[0045] The composite brine drilling fluid of this embodiment comprises the following components by weight: 100 g of water, 0.12 g of sodium hydroxide, 0.15 g of high-viscosity polyanionic cellulose, 0.15 g of low-viscosity carboxymethyl cellulose, and 0.8 g of sulfonated phenolic resin , sulfonated tannin extract 1.2g, superfine calcium carbonate 3g, graphite powder 0.8g, salt-resistant polymer fluid loss reducer (GMP-1, commercially available, purchased from Xinjiang Korla Wanshunda Petroleum Technology Co., Ltd.) 0.5g , sodium formate 5g, sodium chloride 5g, potassium chloride 1.8g.

[0046] The preparation method of the composite brine drilling fluid in this embodiment is as follows: Weigh water, add sodium hydroxide, high-viscosity polyanionic cellulose, low-viscosity carboxymethyl cellulose, sulfonated phenolic resin, and sulfonated tannin extract successively under stirring conditions , superfine calcium carbonate, graphite powder, salt-resistant polymer fluid loss reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com