High speed dispersing equipment, slurry, battery pole piece and lithium ion battery

A high-speed dispersion and equipment technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of equipment dispersion capacity limitation, short slurry residence time, weak shearing effect of the dispersion wheel, etc., to reduce the agglomeration phenomenon, Improves dispersibility and suppresses agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

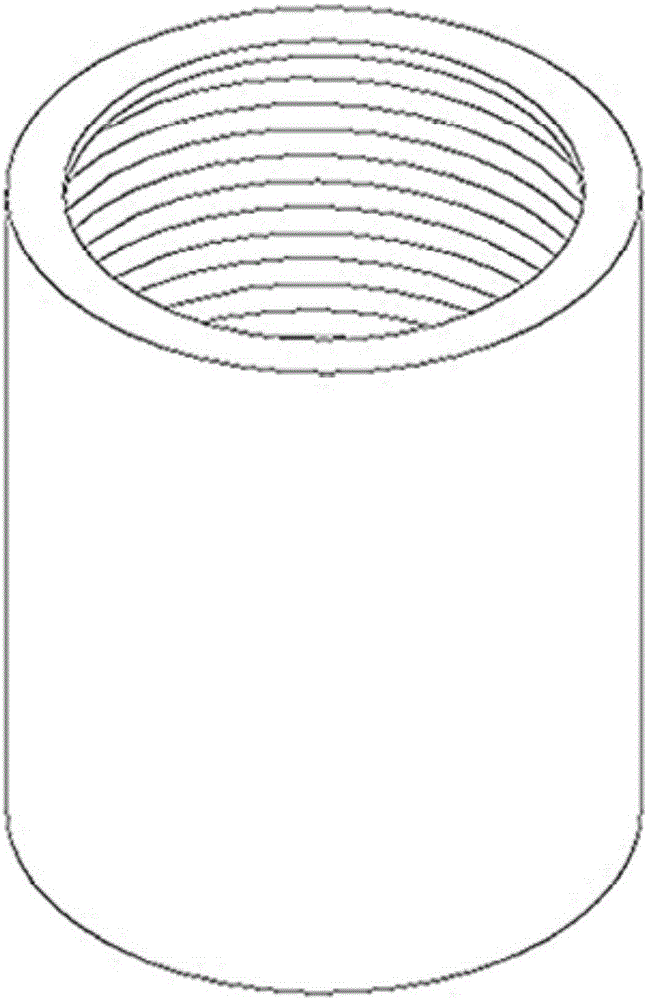

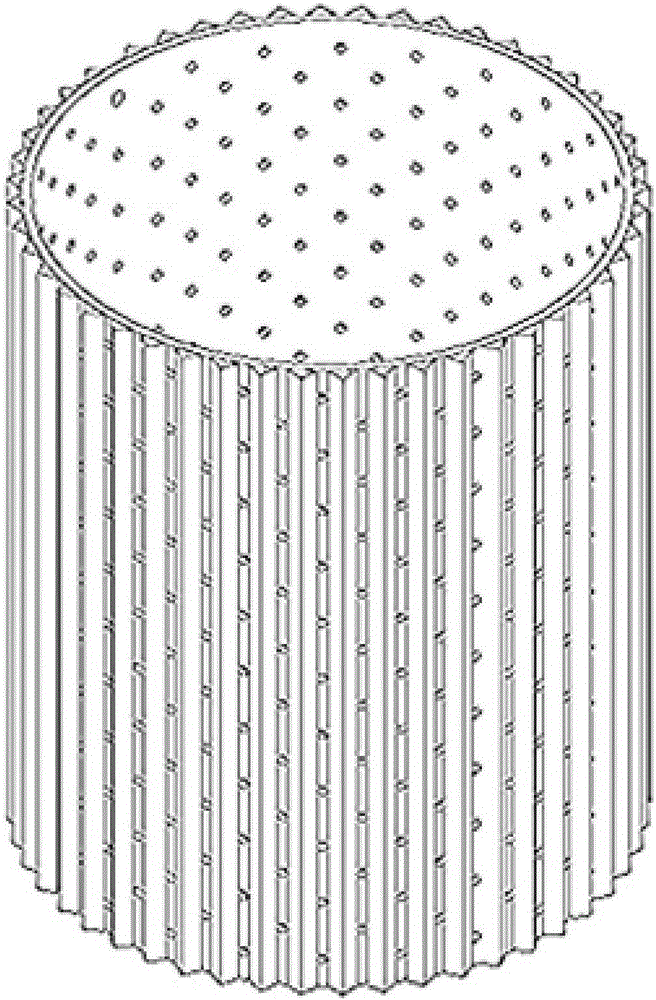

[0051] The inner surface of the side wall of the dispersing barrel is designed to have a spiral track structure, and at the same time ensure that the spiral track structure is: when viewed from the upper end of the dispersing barrel, it climbs up in the counterclockwise direction and the spiral track inwards toward the center of the dispersing barrel . The dispersing wheel is designed to have a tooth-like appearance structure, the tooth-like appearance is distributed on the outer surface of the cylinder of the dispersing wheel and faces the inner wall of the dispersing barrel, and it has an open-pore appearance structure. The opening on the dispersing wheel adopts the appearance of a frustum structure, and its lower bottom surface, that is, the larger bottom surface faces inward to the center of the dispersing wheel (that is, it is set on the inner surface of the cylinder), and the upper bottom surface, that is, the smaller bottom surface faces outward. The structure of the in...

Embodiment 2

[0054] Compared with Example 1, the high-speed dispersing equipment used in this embodiment cancels the tooth-like appearance of the dispersing wheel and adopts a smooth appearance, and at the same time, the opening treatment is carried out on the dispersing wheel, wherein the opening is a cylindrical through hole. The test slurry uses nickel-cobalt lithium manganese oxide as the active material and supplemented by PVDF as the binder, CNT as the conductive material, and NMP as the solvent. Hours of pre-mixing by traditional "planetary-dispersing" mixing equipment, and then dispersing by the high-speed dispersing equipment of this embodiment, and the slurry prepared by this preparation process is designated as slurry A2.

[0055] The above-mentioned slurry is coated on the aluminum foil according to the normal process, and prepared into pole pieces through rolling and cutting processes. After a series of subsequent processes, the finished 18650 battery is finally made.

Embodiment 3

[0057] Compared with Example 1, the high-speed dispersing equipment used in this embodiment cancels the spiral track structure set on the inner wall of the dispersing barrel and chooses a smooth inner wall, and at the same time, the opening treatment is carried out on the dispersing wheel, wherein the opening is a cylindrical through hole . The test slurry uses nickel-cobalt lithium manganese oxide as the active material and supplemented by PVDF as the binder, CNT as the conductive material, and NMP as the solvent. Hours of pre-mixing by traditional "planetary-dispersing" mixing equipment, and then dispersing by the high-speed dispersing equipment of this embodiment, and the slurry prepared by this preparation process is designated as slurry A3.

[0058]The above-mentioned slurry is coated on the aluminum foil according to the normal process, and prepared into pole pieces through rolling and cutting processes. After a series of subsequent processes, the finished 18650 battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com