Preparation method of waterproof grade soybean protein adhesive

A soybean protein glue and adhesive technology, applied in the preparation of animal glue or gelatin, protein adhesives, adhesives, etc., can solve the problem of the adhesive not being waterproof, and achieve the effect of low cost and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

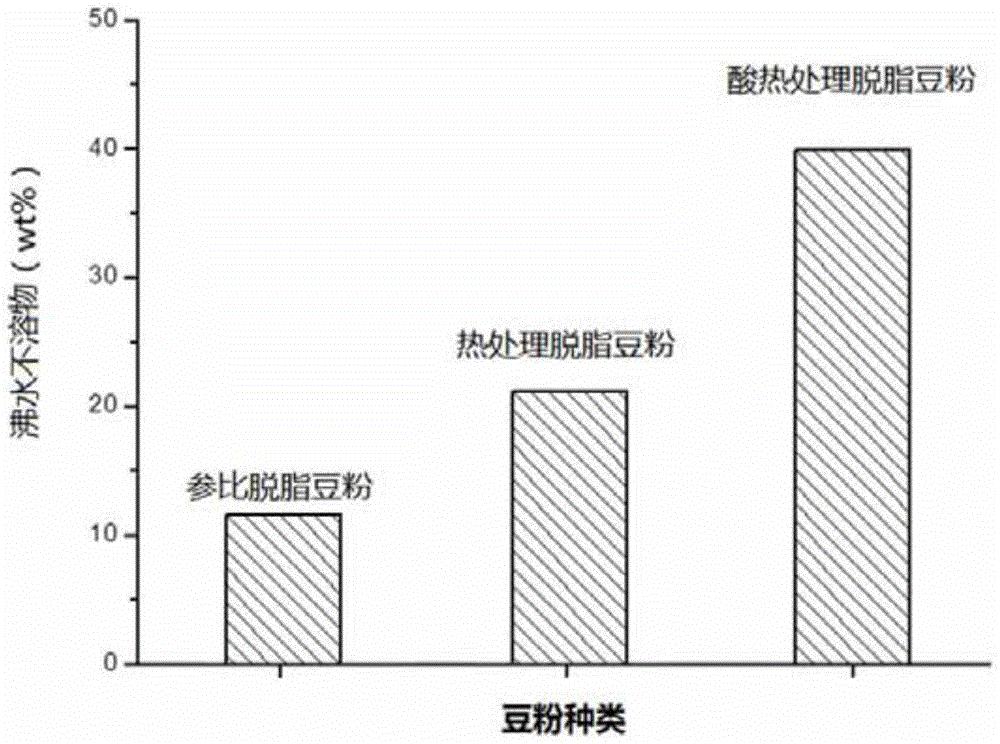

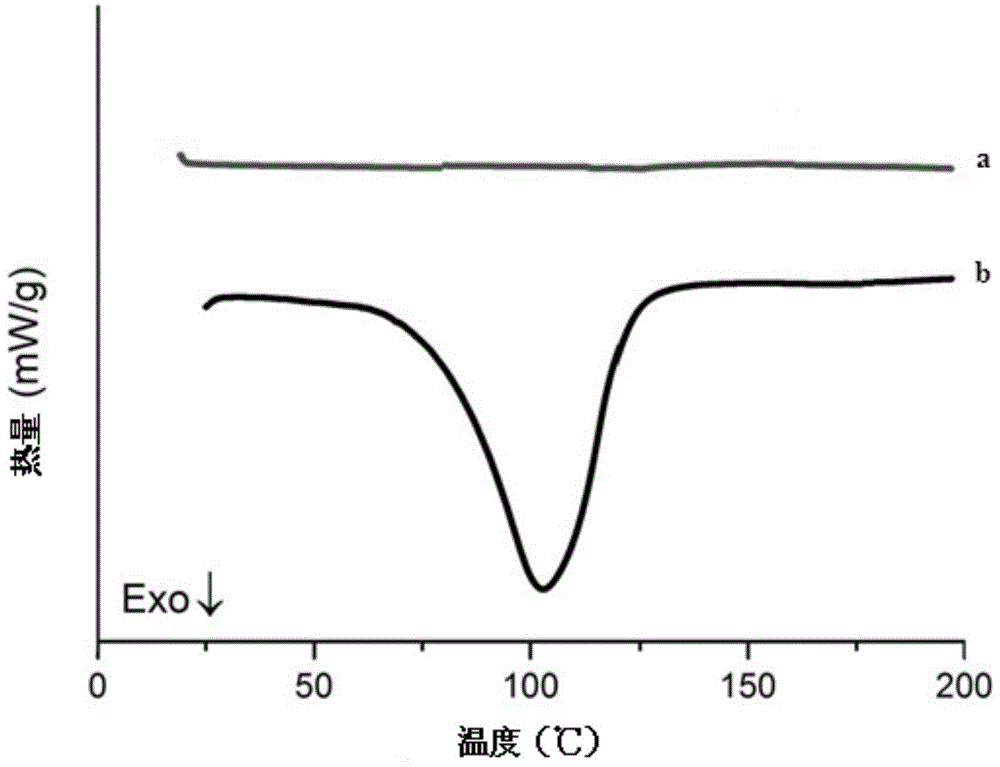

[0041] Specific embodiment 1: The waterproof grade soybean protein adhesive of this embodiment consists of 10-50 parts by weight of acid-heat treated soybean powder, 25-145 parts of soybean powder liquefied product and 9-50 parts of polyamide polyamine solution. Made by mixing at room temperature.

specific Embodiment approach 2

[0042] Embodiment 2: This embodiment differs from Embodiment 1 in that the soybean flour is defatted soybean flour or soybean meal after soybean oil extraction. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the solid content of the soybean powder liquefied product is 20-40 wt%. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com