Spraying system for preparing ultra-efficient solar cell electrode, and application of spraying system

A solar cell, ultra-efficient technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that the electrodes cannot reach the best shape, the conversion efficiency is not optimal, and the distribution of the horizontal height drop is large, so as to improve the product. Pass rate, reduce shading loss, optimize the effect of line shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

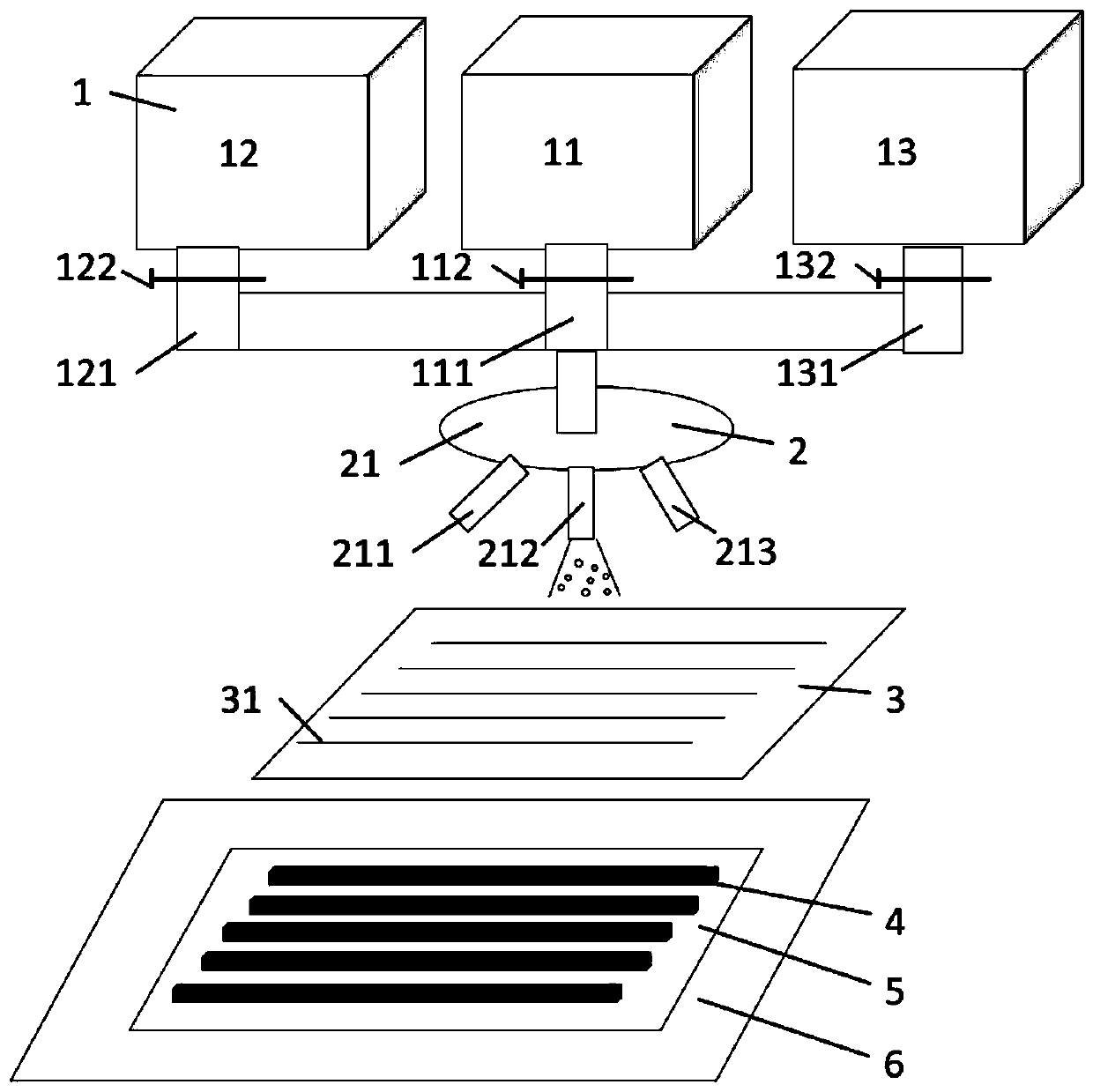

[0038] A spraying system for ultra-efficient solar cell electrode preparation, such as figure 1 , the system includes a slurry storage device 1, a spraying device 2 and a mask 3 to avoid contamination of areas other than the grid lines 4, the slurry storage device 1 and the spraying device 2 are connected by pipelines, and the mask 3 is located between the spraying device 2 and the solar energy between the battery electrodes.

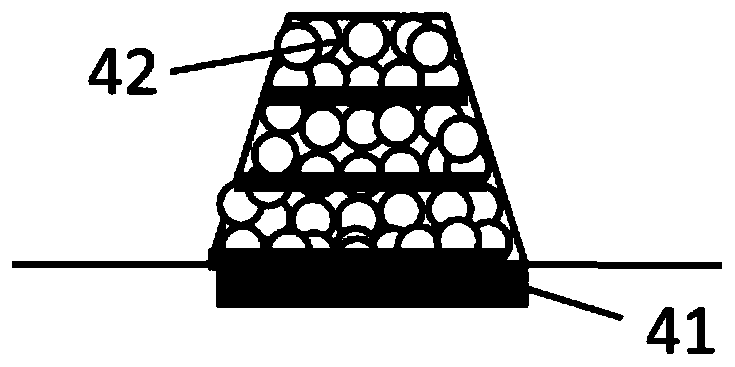

[0039] The solar cell electrode includes a grid line 4 , a carrier 5 and a substrate 6 , the grid line 4 is located above the carrier 5 , the carrier 5 is located above the substrate 6 , and the mask 3 is arranged between the spraying device 2 and the carrier 5 . Disperse the slurry in the slurry storage device 1, keep the slurry in a spin bleaching state, and then spray the slurry through the mask 3 through the spraying device 2, so that the grid lines 4 are formed on the carrier 5, and then the ultra-high-efficiency solar cell is produced electrode....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com