Patents

Literature

60results about How to "Process raw materials are easy to get" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479ALattice stabilizationGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentSlurryZircon

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

Preparation method of titanium pigment used in ship paint

ActiveCN102226043AGood dispersionGood weather resistancePigment treatment with organosilicon compoundsSilicon oxideSlurry

The invention discloses a preparation method of titanium pigment used in ship paint. The method comprises the following steps that: a. metatitanic acid is calcined, such that a titanium pigment crude product is obtained, the titanium pigment crude product is prepared into TiO2 slurry, and sodium hexametaphosphate is added to the slurry; b. the slurry is heated, a silicon-containing compound is added to the slurry, and the slurry is homogenized; c. the pH value of the TiO2 slurry is regulated to 0.8 to 4; d. after the slurry is slaked, an organic dispersant is added to the slurry, an aluminum-containing compound is added to the slurry, and the mixture is homogenized; e. the pH value of the TiO2 slurry is regulated to 4 to 8; f. the TiO2 slurry is slaked; g. the TiO2 slurry is filtered, such that the resistivity of the filter cake is greater than or equal to 100 [omega]M; and the filter cake is dried and heat treated; h. an organic surface conditioning agent is added to the filter cake, and the filter cake is crushed, such that the finished product is obtained. According to the present invention, nano-sized silicon oxide sol and alumina sol are prepared sequentially. Through physical adsorption and chemical absorption, a compact coating layer is formed on the surface of the TiO2 particles. Then, the coating layer is firmly attached to the surface of the TiO2 particles through chemical deposition. With the coating layer, the product provided by the present invention possesses good dispersibility, weatherability and corrosion resistance. Meanwhile, according to the method provided by the present invention, the raw materials are easy to obtain, the processes are smooth and are easy to control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

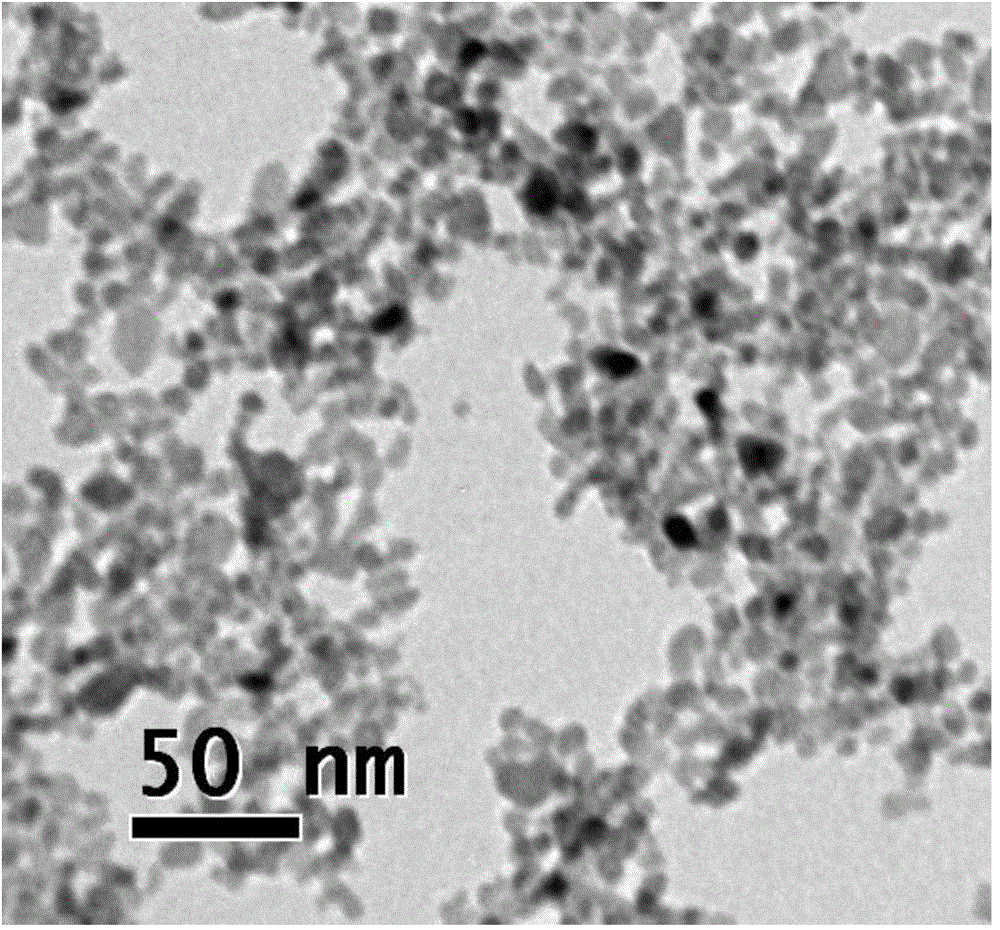

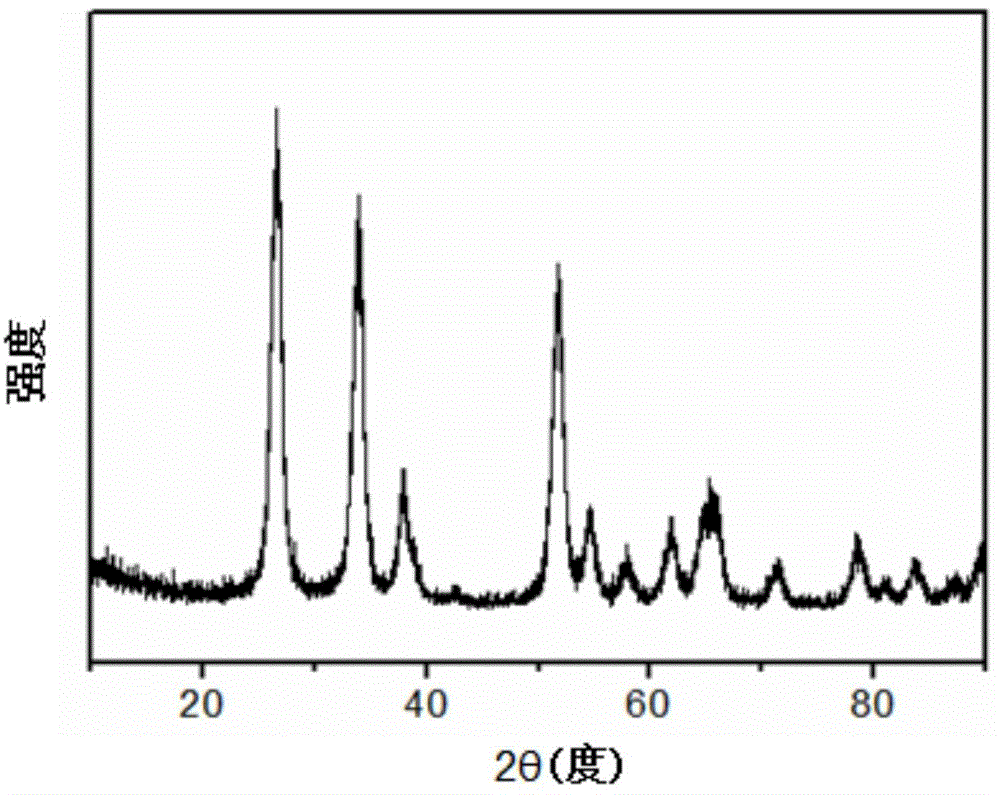

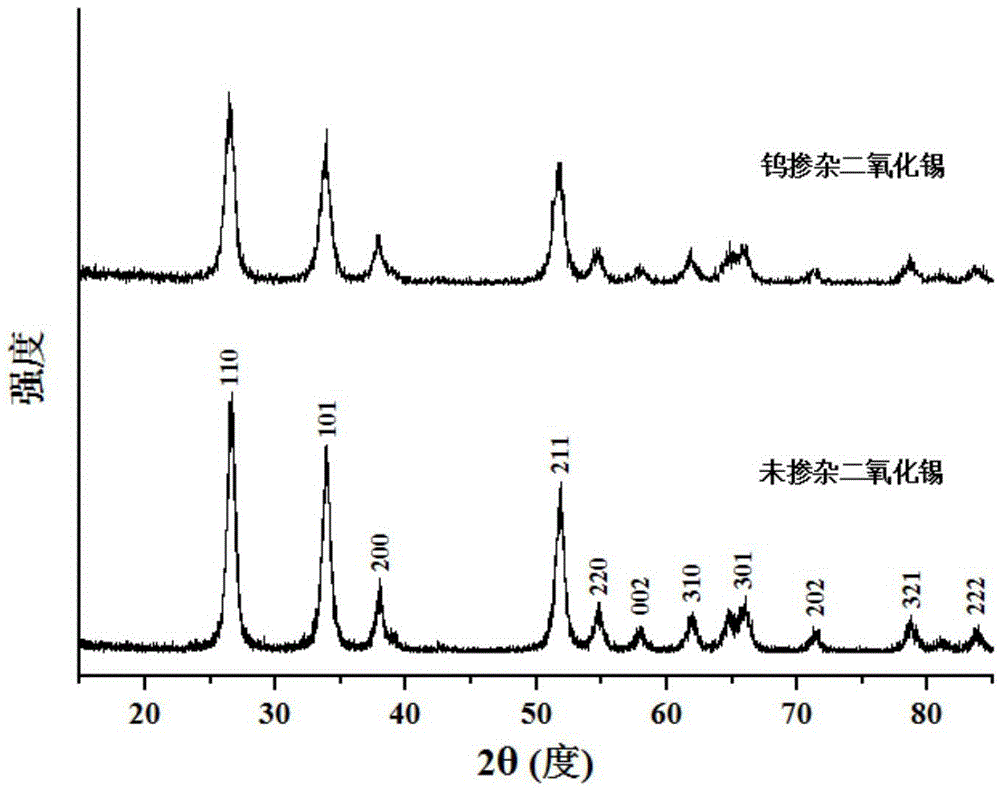

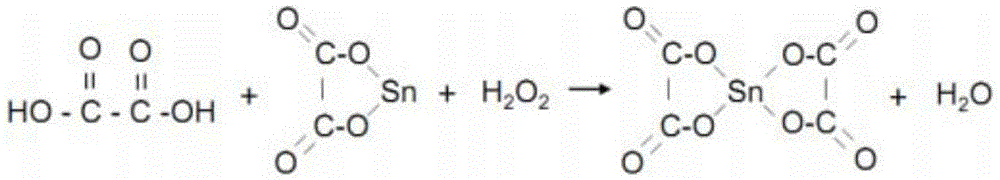

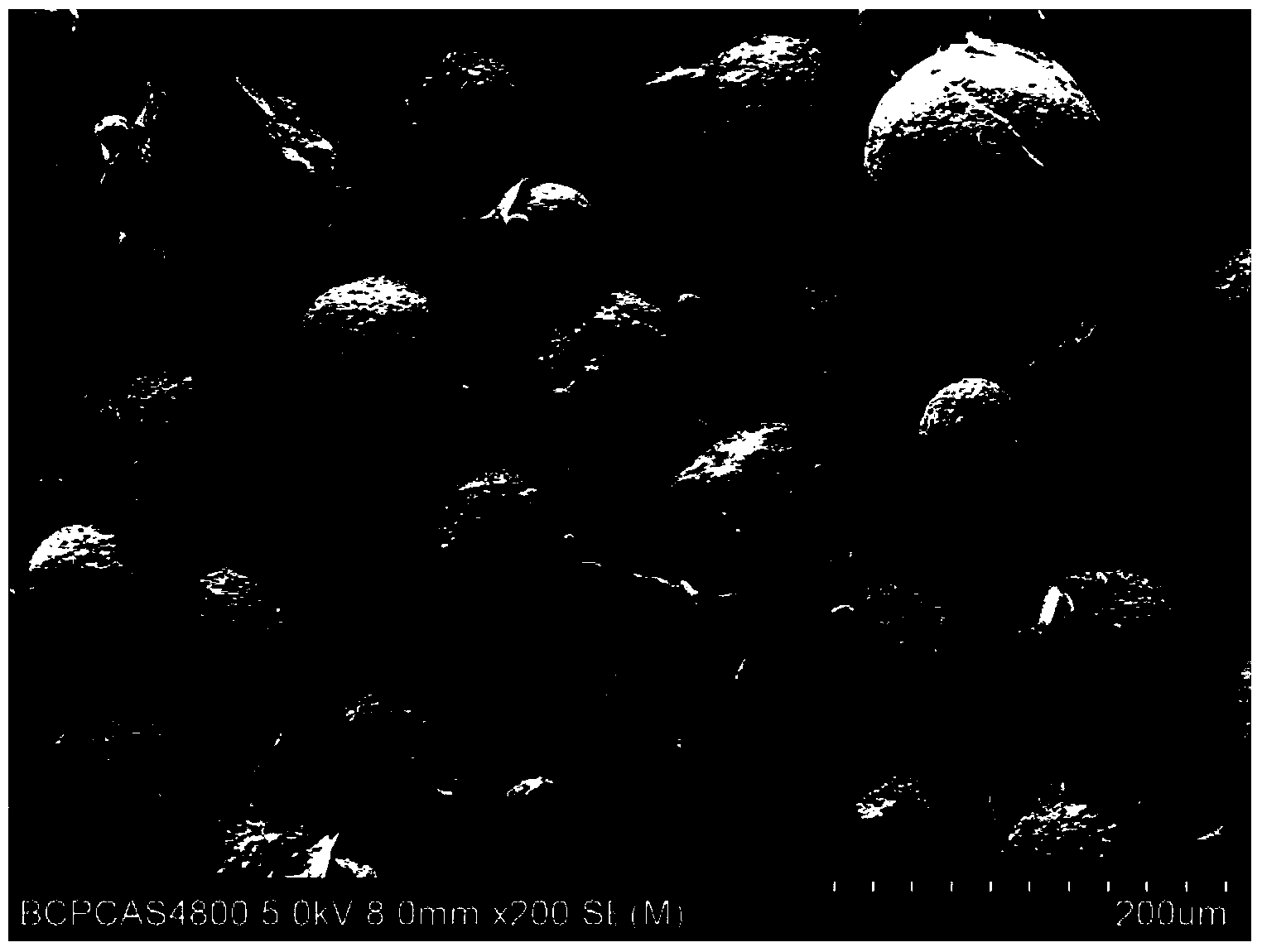

Preparation method of doped stannic oxide conductive nano powder

ActiveCN104150528ACreate pollutionProcess raw materials are easy to getMaterial nanotechnologyTin oxidesTin dioxideIce water

The invention belongs to the field of nano materials, and particularly relates to a preparation method of doped stannic oxide conductive nano powder. The preparation method is characterized by preparing the nano powder through a hydrothermal method. The method provided by the invention comprises the following steps of weighing stannous oxalate, adding hydrogen peroxide in an ice-water bath; adding water when the above system reacts to form a transparent solution; adding a fluorine- or stibium-containing material in the solution as a dopant; mixing uniformly; carrying out hydro-thermal treatment; washing and drying to obtain the doped stannic oxide conductive nano powder. The preparation method can obtain the doped stannic oxide conductive nano powder with uniform particle size, good dispersibility and high purity without high-temperature calcination. The preparation method has easily-available raw materials, extremely simple flow, high efficiency and good repeatability, and is beneficial for large-scale production.

Owner:PANZHIHUA UNIV

High epoxide number environment-friendly plasticizer production process

InactiveCN102503912AHigh epoxy valueProcess raw materials are easy to getFatty acid esterificationSulfonic acid esters preparationSodium methoxideMethyl oleate

The invention discloses a high epoxide number environment-friendly plasticizer production process. The production process comprises the following steps of: adding cottonseed oil, methanol and sodium methoxide into an ester exchange reactor for reaction to obtain mixed fatty acid methyl ester; adding into a rectifying tower for separation, and performing epoxidation, neutralization, washing and dehydration on methyl oleate obtained from the tower bottom to obtain a high epoxide number environment-friendly plasticizer; and performing sulfonation reaction on palmitic acid methyl ester obtained from the tower top and sulfur trioxide, and ageing, esterifying, neutralizing and drying to obtain an environment-friendly surfactant MES. By the production process, the raw materials are readily available, the process is advanced, equipment is simple, the high epoxide number plasticizer can be prepared, and the byproduct, namely the palmitic acid methyl ester can be used for producing the environment-friendly surfactant.

Owner:扬州市双全塑胶材料厂

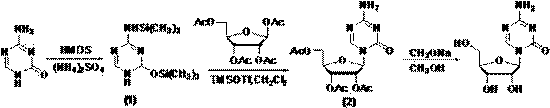

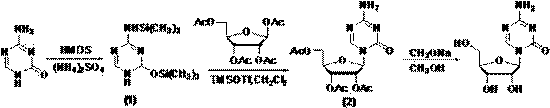

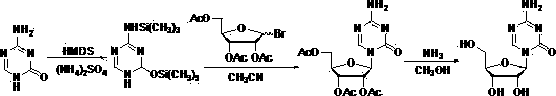

Synthetic method of azacitidine

InactiveCN103524584AAvoid processing powerProcess raw materials are easy to getSugar derivativesSugar derivatives preparationTriflic acidAzacitidine

The invention discloses a synthetic method of azacitidine. The synthetic method comprises the following steps: with 5-azacytosine and tetraacetylribose as raw materials, protecting the raw materials by using trimethyl silicon, then performing butt joint on the raw materials together with 1,2,3,5-tetra-O-acetyl-beta-D-ribose under the catalysis of Lewis acid trimethylsilyl triflate to obtain glycoside, performing alcoholysis to remove protective groups, and performing recrystallization to obtain the azacitidine. According to the synthetic method disclosed by the invention, the 5-azacytosine and the tetraacetylribose are used as the raw materials, and in the reaction of obtaining the glycoside through butt joint, the Lewis acid trimethylsilyl triflate (TMSOTf) replaces tin tetrachloride, so that the problems that a crude metallic tin is overproof and after treatment causes emulsification easily and is inconvenient are avoided, process raw materials of the synthetic method are easy to obtain, and the synthetic method is simple in operation, high in yield, less in step, environment-friendly, and suitable for industrial production.

Owner:TIANJIN JIUHAI MEDICAL TECH

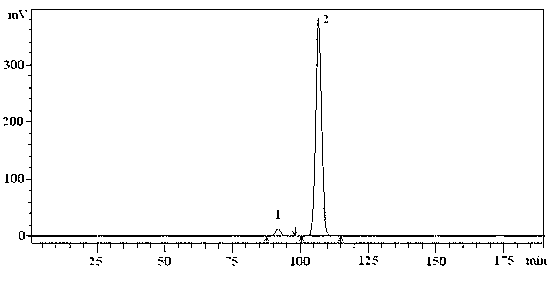

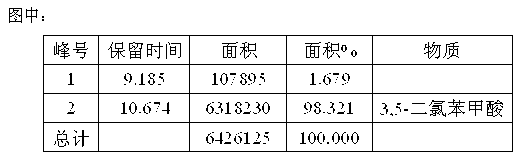

Method for synthesizing 3,5-dichlorobenzoic acid

ActiveCN103224451AHigh safety of chlorinationHigh purityPreparation from carboxylic acid saltsPreparation from nitrilesProcess engineeringBenzonitrile

The invention discloses a method for synthesizing 3,5-dichlorobenzoic acid, which comprises the following steps: chlorinating benzonitrile used as a raw material to generate 3,5-dichlorobenzonitrile; and then, performing hydrolysis and acidification reaction to obtain 3,5-dichlorobenzoic acid. According to the invention, the benzonitrile is used as the raw material; sodium hypochlorite or a mixture of oxydol and hydrochloric acid is used in the chlorination process; the traditional chlorine gas chlorination process is omitted; the obtained 3,5-dichlorobenzonitrile is high in purity; no diazotization procedure is required; and the process safety is enhanced. The process has the advantages of accessible and cheap raw material, low production cost of the product, high process safety coefficient and short process flow, is simple to operate, is more beneficial to industrial production, is a new process for synthesizing 3,5-dichlorobenzoic acid, and provides a new idea for synthesizing propyzamide.

Owner:SHANDONG WEIFANG RAINBOW CHEM

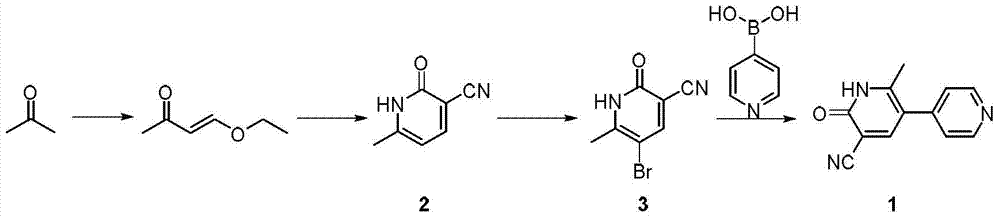

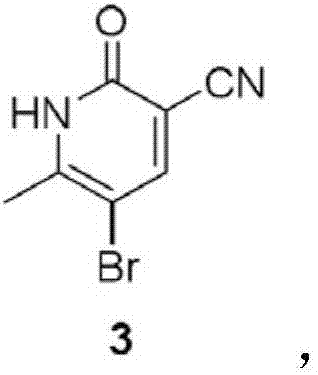

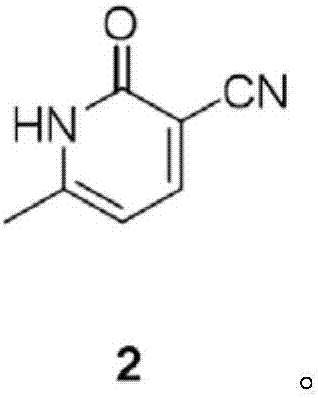

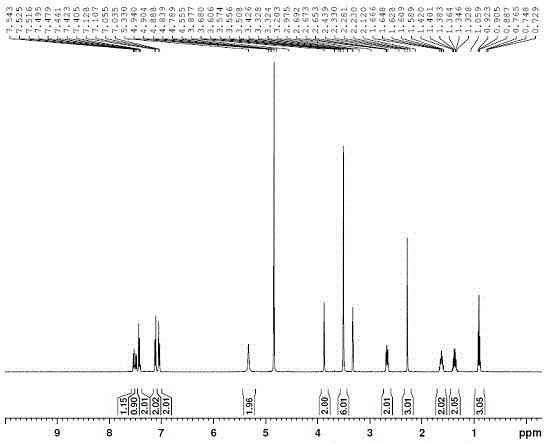

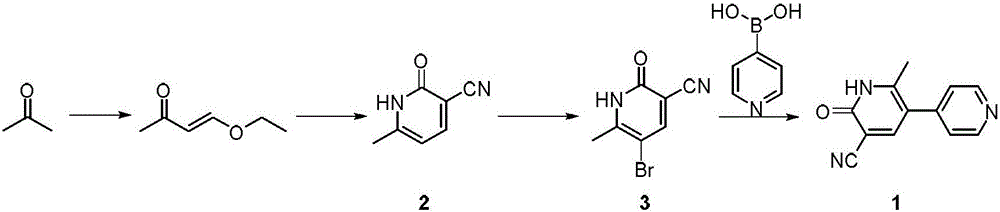

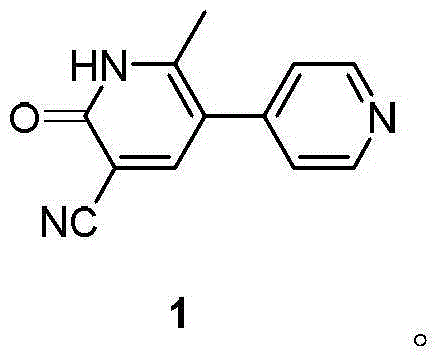

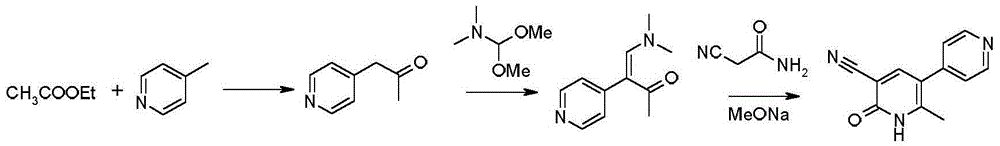

A kind of method of synthesizing milrinone

The invention discloses a new method for synthesizing milrinone. The method is characterized in that a compound of formula 3 and 4-pyridineboronic acid undergo a Suzuki coupling reaction to synthesize milrinone. The method has the advantages of easily available raw materials, high yield and simple post-treatment.

Owner:HUNAN SAILONG PHARMA

Preparation method of fimasartan potassium salt hydrate

InactiveCN105061405AReduce usageProcess raw materials are easy to getOrganic chemistryBulk chemical productionTetrazolePotassium

The present invention discloses a preparation method of a fimasartan potassium salt hydrate. The method is as below: reacting a starting material 1(2-(2-butyl-4-hydroxy-6-methylpyrimidine-5-yl)-N,N-dimethylacetamide) with a starting material 2 (N-(triphenylmethyl)-5-(4'-bromomethyl-biphenyl-2-yl) tetrazole) in the presence of an alkali metal hydride in a mixed solvent of ethyl acetate and DMF, so as to obtain a compound IV; hydrolyzing the compound IV under acidic conditions to remove the protective group to obtain a compound III; subjecting the compound II to a thioamidation reaction with a Lawesson's reagent to obtain a compound II; and subjecting the compound II and potassium hydroxide to a salt-forming reaction in a mixture of isopropyl alcohol and water to obtain a desired product. The present invention has the advantages of easily available process feedstock, mild reaction conditions at room temperature, economical performance, environment-friendliness and easiness to operation, reduces the process cost to a large extent, and is easy to realize industrial production.

Owner:合肥创新医药技术有限公司

Preparation process for novel bone meal

ActiveCN102726599AIncrease profitIncrease added valueAnimal feeding stuffFood preparationHigh energyOperability

The present invention relates to a preparation process for novel bone meal. According to the process, marine fishing trash fishes are subjected to enzymolysis to obtain an activity peptide; the resulting enzymolysis waste from the enzymolysis reaction is adopted as a raw material, and is cleaned until the filtrate is clarified and does not contain water-soluble impurities, and then a drying treatment is performed; a screening treatment is performed to obtain a raw material fish bone; and the raw material fish bone is subjected to treatments of fat removing, impurity protein removing, collagen protein removing, filtering, deodorization, drying, crushing and the like. The preparation process of the present invention has characteristics of easily available raw materials, reasonable process design, strong operability, and controllable quality. With the preparation process, a high pressure hot water extraction method is adopted to remove collagen protein in the raw materials; the prepared bone meal has advantages of high purity, low loss rate, low processing cost and the like; and the ordinary hot water extraction method is optimized, disadvantages of long collagen protein removing time, low removal rate, and high energy consumption are overcome, and finally the bone meal preparation process applicable for industry production is determined so as to prepare the food grade and feed grade bone meal with the high added value.

Owner:JIANGSU TIANFULAI GROUP

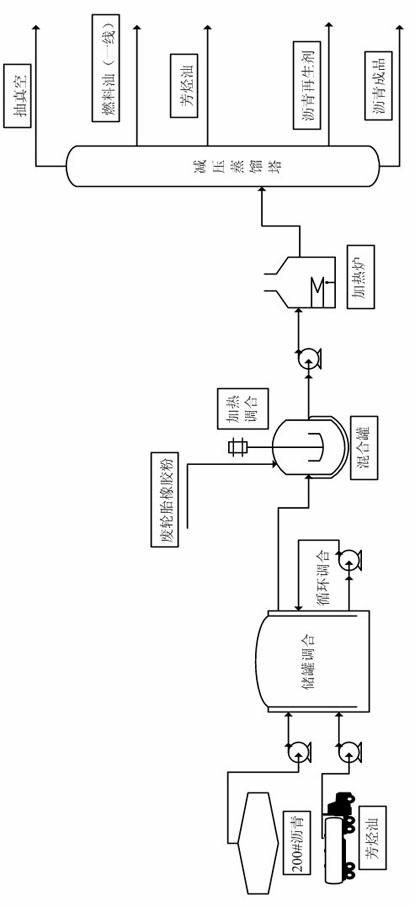

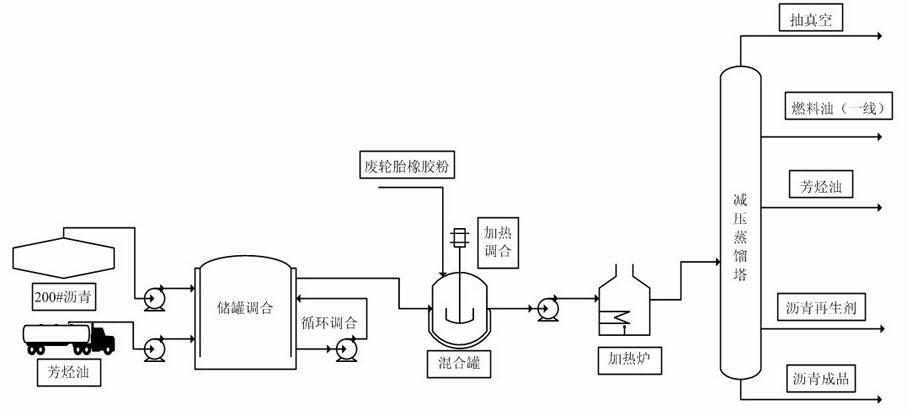

Modified production method of asphalt

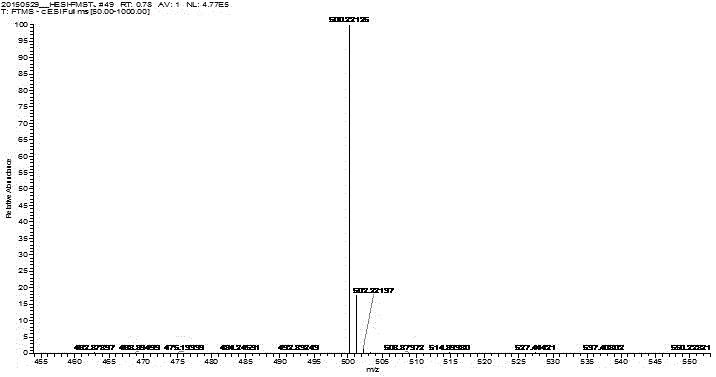

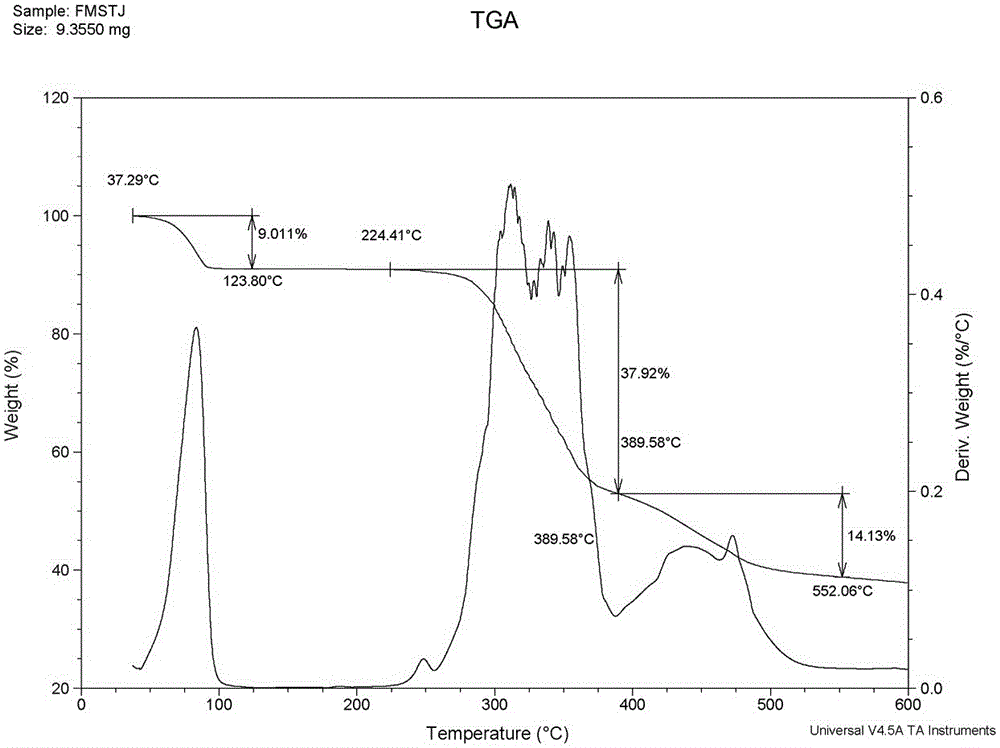

InactiveCN102250475AProcess raw materials are easy to getSimple processBuilding insulationsHigh energyFuel oil

The invention discloses a modified production method of asphalt. The modified production method provided by the invention comprises the following steps of: by utilizing waste rubber powder as a modified raw material, dissolving aromatic hydrocarbon oil components into non-road asphalt or standard road asphalt at a temperature in a range of 60-80 DEG C; then dissolving the waste rubber powder into the mixture at a temperature in a range of 180-220 DEG C and mixing to form a mixed asphalt raw material; finally, heating the mixed asphalt raw material to more than 300 DEG C and separating out fuel oil and the aromatic hydrocarbon oil through use of a continuous decompression and distillation method to obtain an asphalt regenerating agent and an asphalt finished-product. The modified production method provided by the invention has the advantages of easily-obtained raw materials, simple process, economical cost, no additional auxiliary agents and no influence on the environment; and a multi-stage variable-temperature dynamic dissolution process is adopted in the method so that the waste rubber components can be completely dissolved in the asphalt raw material, have good stability and do not chromatograph again. Particularly, the production method does not need use of complicated and high-energy-consumption special devices, such as a high-speed cutting emulsifying machine, a grinder and the like; and the production scale is easy to enlarge.

Owner:SUZHOU INDAL PARK DAHUA GASOLINEEUM

Tungsten-doped stannic oxide sol nanocrystalline and preparing method thereof

InactiveCN105540650AProcess raw materials are easy to getSimple processMaterial nanotechnologyTin oxidesSolventTungsten

Owner:PANZHIHUA UNIV

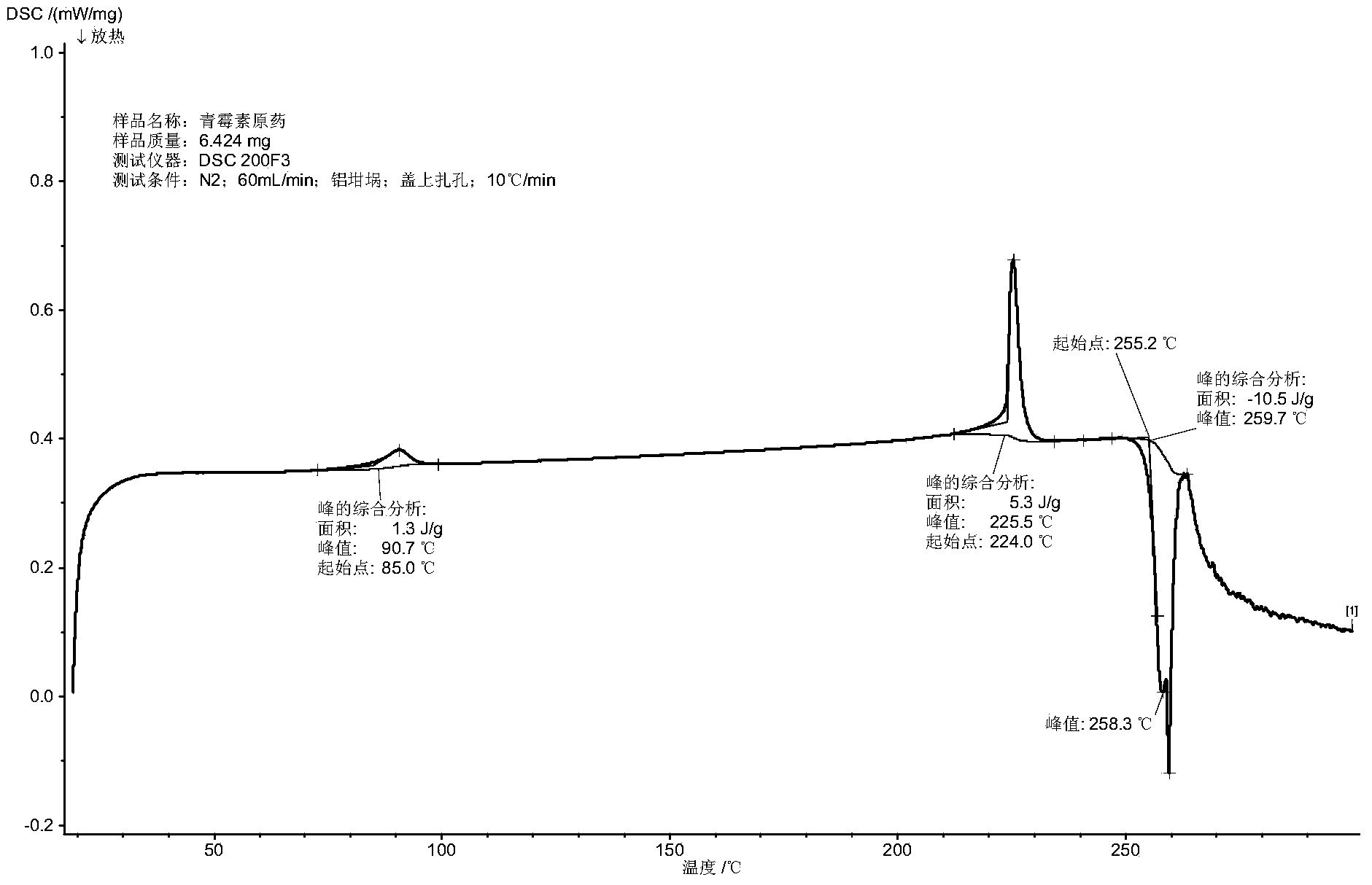

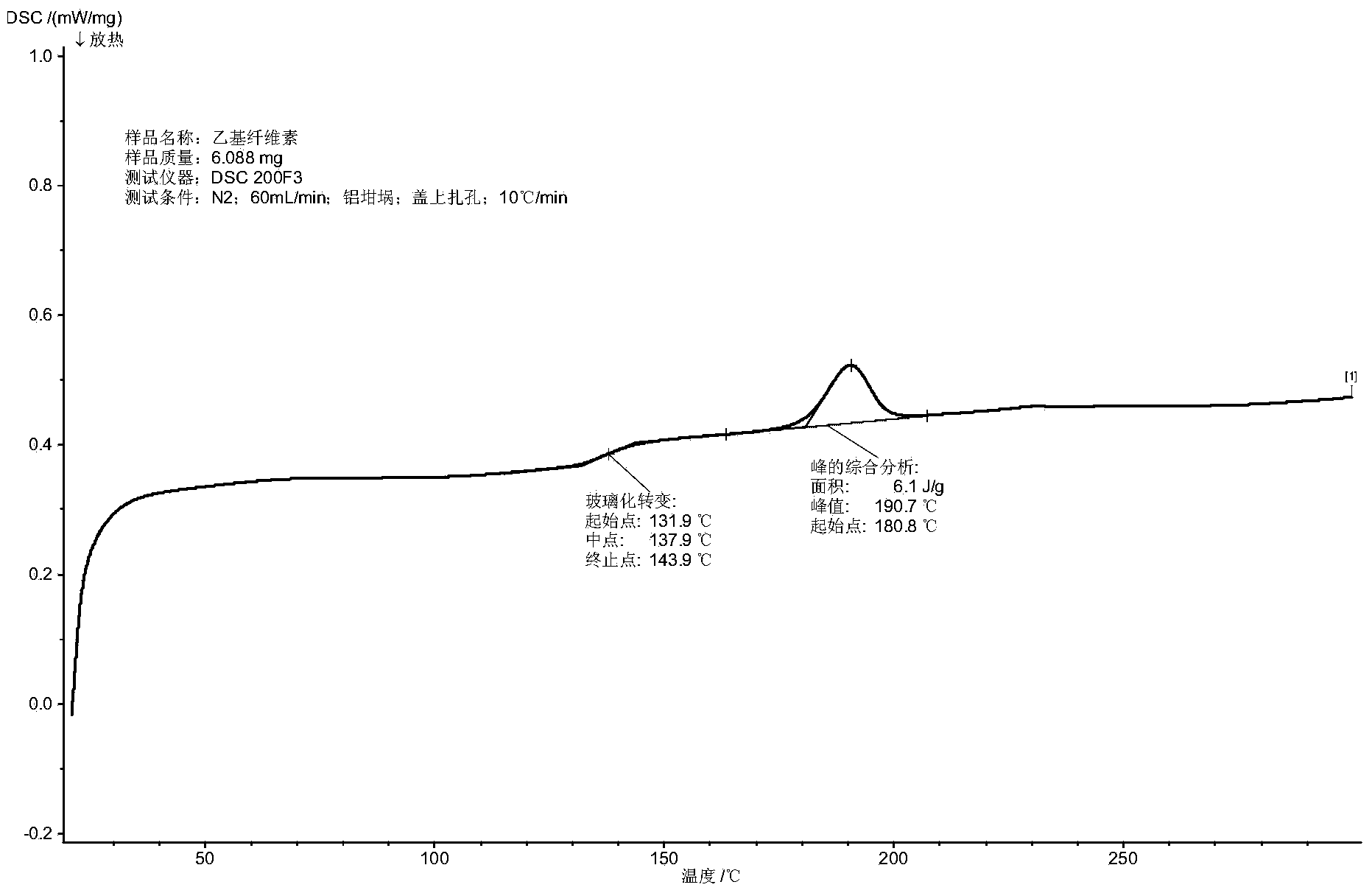

Penicillin V potassium micro-capsule and preparation method thereof

InactiveCN103893150AEliminate bad smellImprove compliancePharmaceutical non-active ingredientsMicrocapsulesDichloromethanePatient compliance

The invention discloses a penicillin V potassium micro-capsule and a preparation method thereof. The penicillin V potassium micro-capsule consists of a core material penicillin V potassium and a capsule wall material ethyecellulose. The preparation method comprises the following steps: 1) smashing and dissolving ethyecellulose in dichloromethane to obtain a solution a; 2) dissolving the smashed penicillin V potassium under stirring at a rotating speed of 100-500rpm in the solution a to obtain a solution b, and continuously stirring for 20-30 minutes; 3) controlling temperature of water and dispersing a surfactant in water to obtain a solution c; and 4) under the condition of stirring at a speed of 100-500rpm, adding the solution b into the solution c to form the penicillin V potassium micro-capsule, continuously stirring till dichloromethane is fully volatilized, filtering under reduced pressure, and washing the micro-capsule three times by using distilled water, and drying to obtain the penicillin V potassium micro-capsule. According to the invention, the micro-capsule is prepared by a drying-in-liquid method to eliminate harmful smell of penicillin V potassium so as to improve the compliance of the patient. The preparation process of the micro-capsule uses easily available and low-price raw materials, is low in production cost, simple in process operation, easy to operate and implement and high in yield.

Owner:北京中科锐进科技有限责任公司

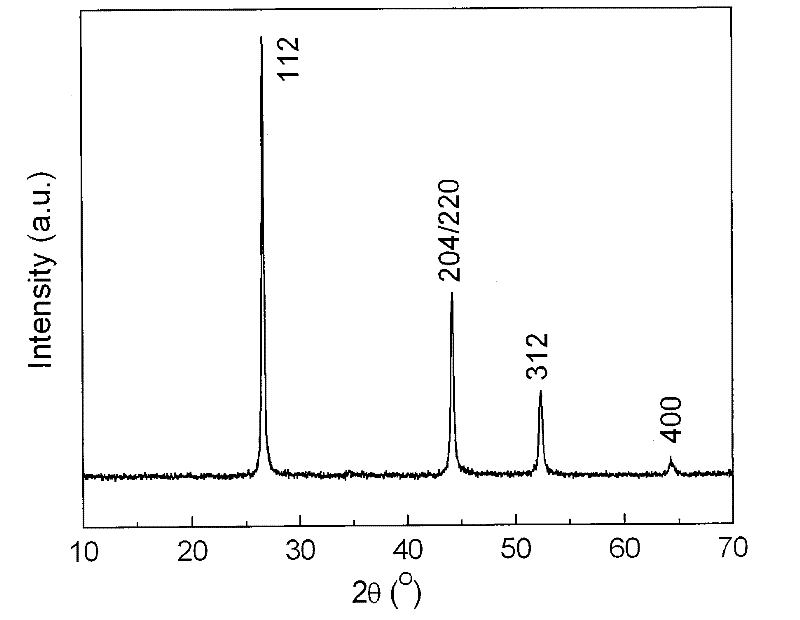

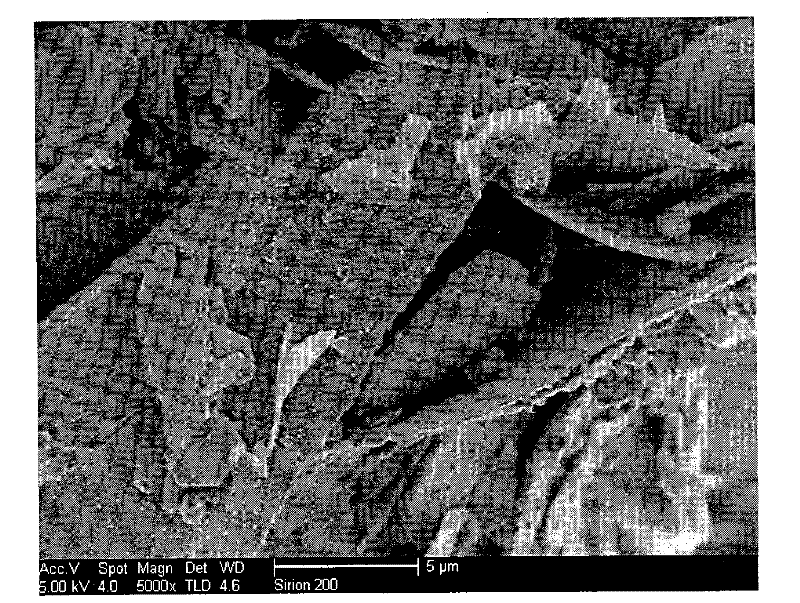

A kind of porous sheet-like cuinse2 nanometer material and preparation method thereof

InactiveCN102295275ANovel structureImprove performanceSelenium/tellurium compundsElectrical batteryPorous sheet

The invention discloses a porous flaky CuInSe2 nanometer material and a preparation method thereof, which adds a new variety to the CuInSe2 nanostructure material and fills up the gap in the prior art at home and abroad. The CuInSe2 nanostructure material has a sheet structure, the nanometer size is 5-20 microns, and the thickness of the nanosheet is 200-600 nanometers. The surface of the nanosheet is very rough, assembled by particles with a particle size of 20-40 nanometers, rich in a large number of microporous structures with a pore size of 20-25 nanometers. The porous flaky CuInSe2 nanomaterial of the present invention is prepared by a mixed solvothermal method, that is, using CuCl2 2H2O, InCl3 4H2O and SeO2 as raw materials, in a mixed solvent of ethylene glycol and ethylenediamine, through a one-step solvothermal reaction. to make. The porous flaky CuInSe2 nanometer material obtained in the invention is a solar cell material with novel structure and superior performance, and can be developed and applied in the field of solar cells. The preparation process of the invention has easy-to-obtain raw materials, simple equipment, low cost, easy operation and good repeatability, and is suitable for industrialization.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

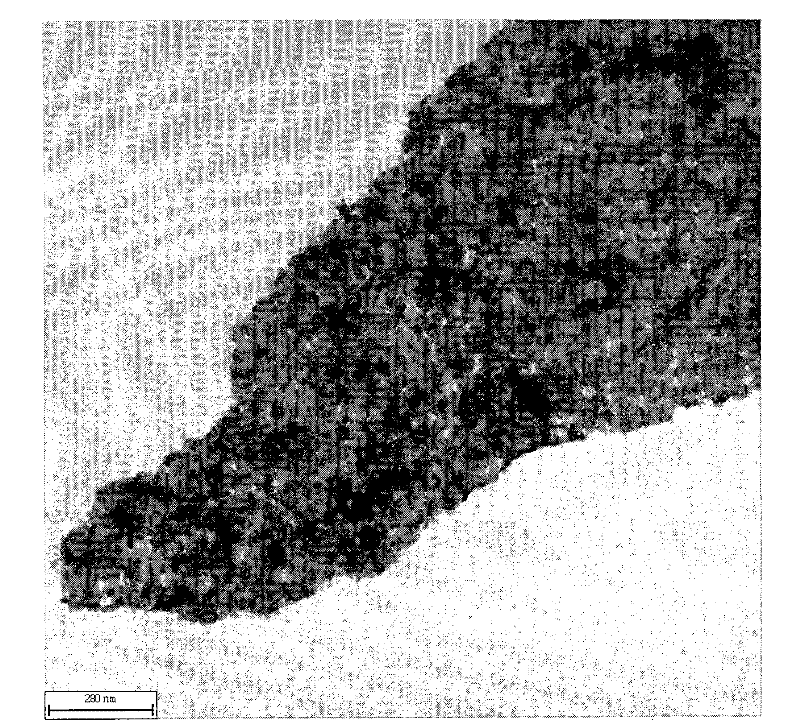

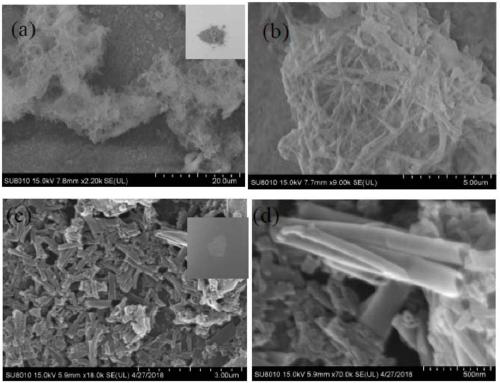

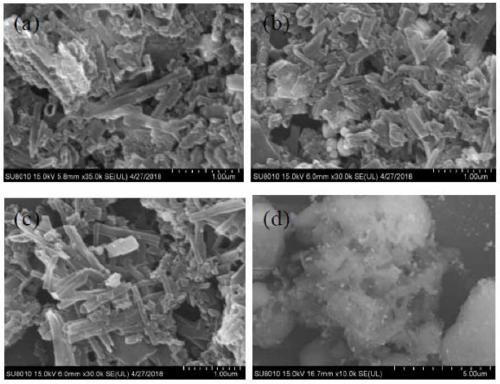

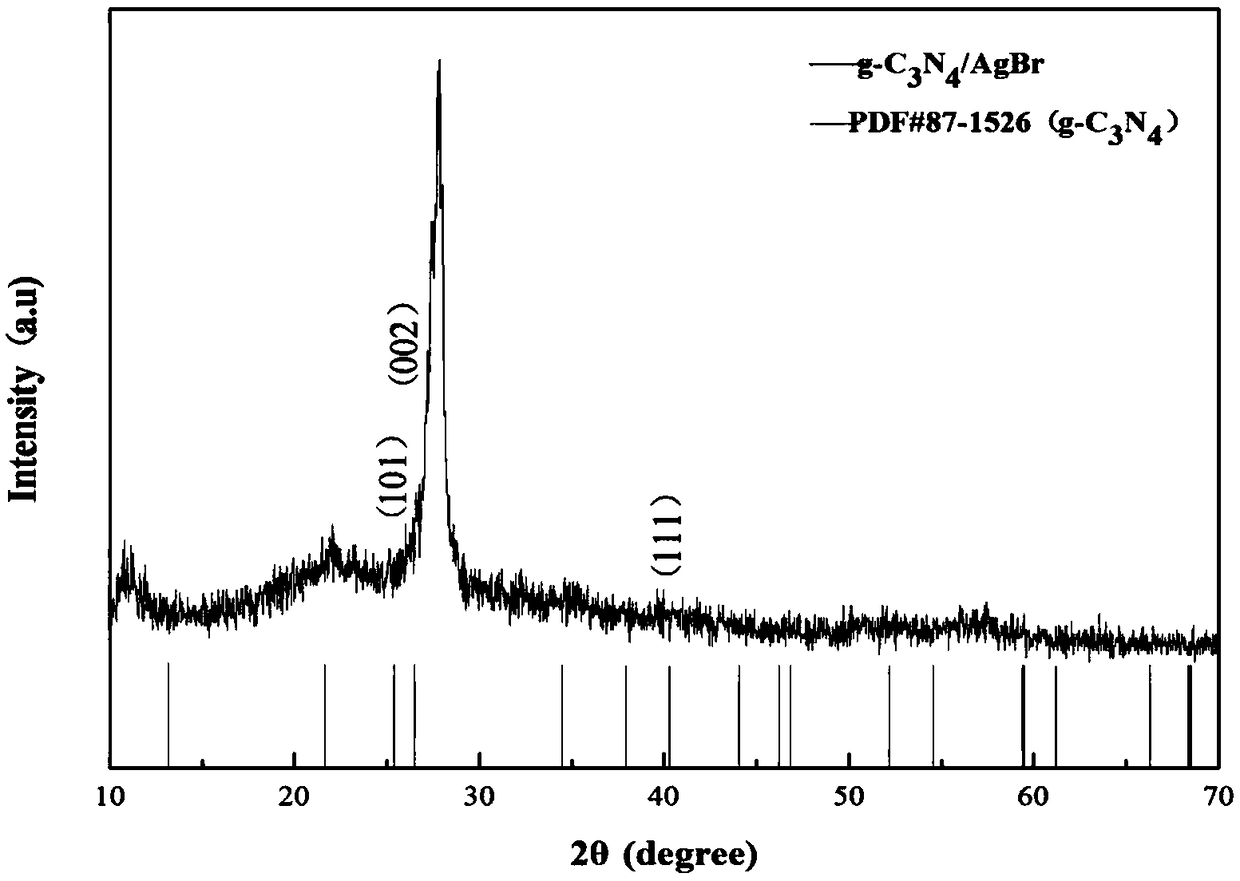

Preparation method and applications of AgBr/g-C3N4 composite powder

ActiveCN108927201AImprove stabilityBroaden the response rangeWater/sewage treatment by irradiationWater treatment compoundsUreaCyanuric chloride

The invention provides a preparation method and applications of AgBr / g-C3N4 composite powder, and relates to the technical field of composite powder preparation. The preparation method comprises following steps: adding cyanuric chloride, melamine, and urea into a beaker, measuring acetonitrile, pouring acetonitrile into the beaker, stirring to disperse acetonitrile; after stirring, pouring the mixture into a reactor, covering the reactor, placing the reactor in a temperature-constant blowing baking oven to carry out reactions; after reactions, filling generated substances into a plastic tube,carrying out centrifugation, washing, and drying to obtain rod shaped or tube shaped g-C3N4; weighing g-C3N4, silver nitrate, and CTAB, adding g-C3N4, silver nitrate, and CTAB into a beaker, adding anhydrous ethanol; carrying out reactions under the assistance of ultrasonic waves in the beaker, after reactions, pouring the reaction product into a plastic tube, and carrying out centrifugation, washing, and drying to obtain AgBr / g-C3N4 composite powder. The composite powder has a large specific surface area, the pore volume is 0.110 cc / g, the pore diameter is 17.171 nm, and the composite powderhas an excellent performance of degrading common organic dyes in the presence of visible light.

Owner:HEFEI UNIV

Synthesis method of cyclopropanecarboxylic acid

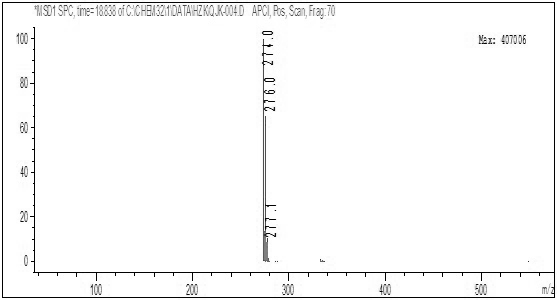

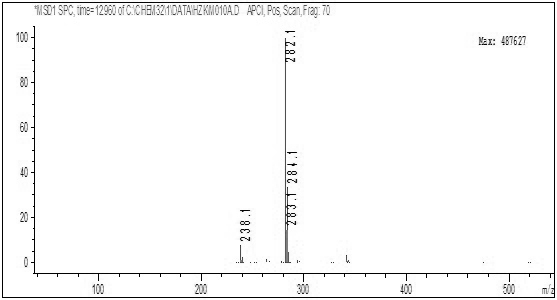

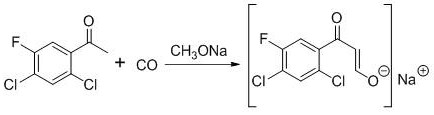

The invention discloses a synthesis method of cyclopropanecarboxylic acid. The synthesis method comprises the following steps: with 2,4-dichloro-5-fluoro-acetophenone and carbon monoxide as raw materials, generating sodium beta-2,4-dichloro-5-fluoro-benzoylvinyl alcoholate under the action of sodium methoxide at high pressure, then carrying out amination via cyclopropylamine salt, and successively carrying out reactions such as cyclization, beta-keto acid esterification, hydrolysis and the like to prepare cyclopropanecarboxylic acid. According to the invention, synthesis raw materials are easy to obtain, a synthesis process is simple, reaction conditions are mild, production cost is reduced, production safety is ensured, and the method is suitable for industrial production.

Owner:SHANDONG GUOBANG PHARMA +1

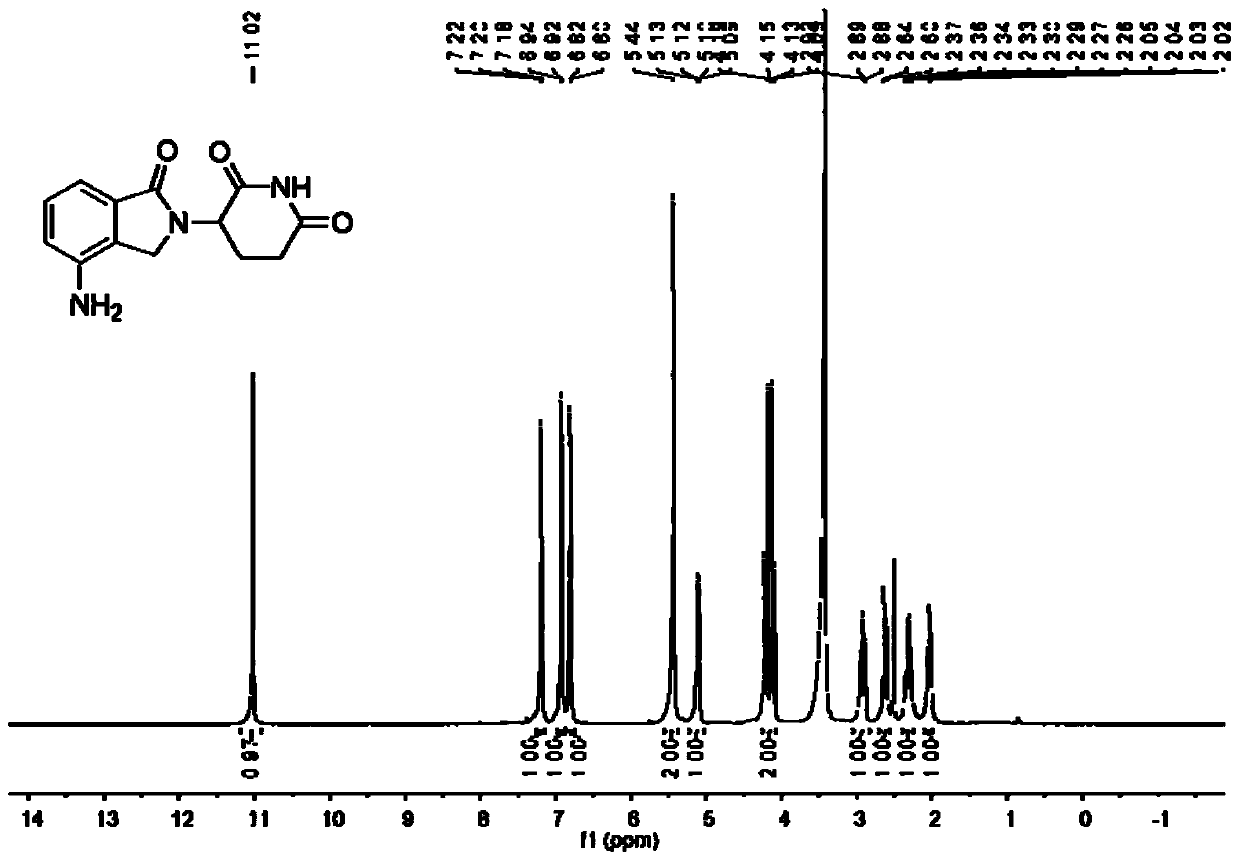

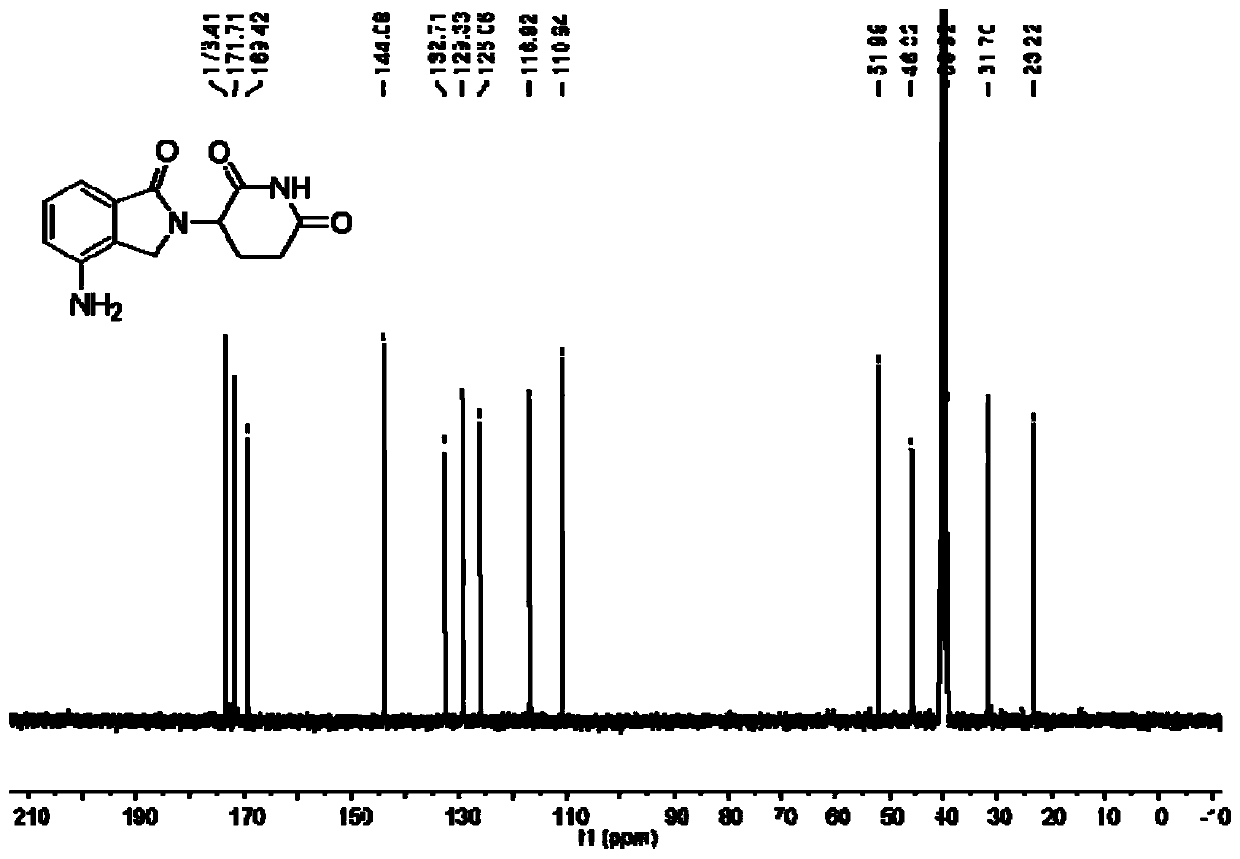

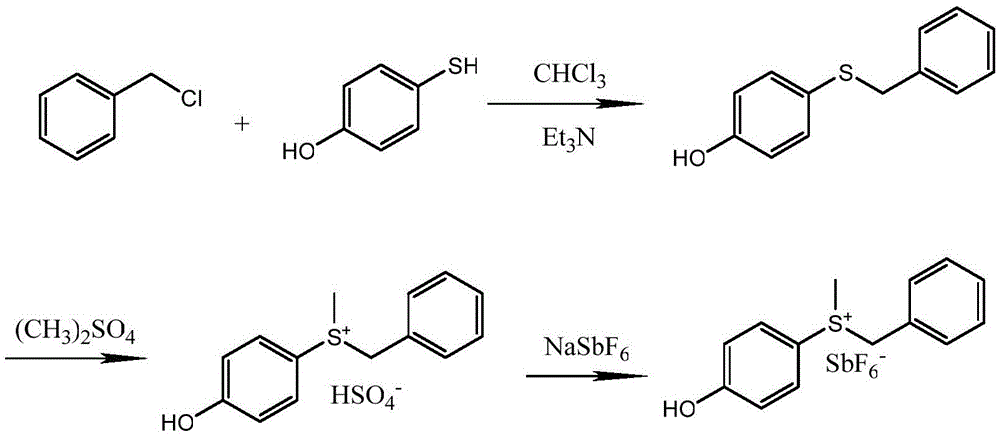

Method for synthesizing lenalidomide

InactiveCN110642834ARealize green productionProcess raw materials are easy to getOrganic chemistryChemical synthesisBenzoic acid

The invention belongs to the field of chemical synthesis, and particularly relates to a method for synthesizing lenalidomide. The method adopts three-step polymerization, and specifically comprises: (1) carrying out a bromination reaction on 2-methyl-3-nitromethyl benzoate as a starting raw material and a bromination reagent to generate a compound 1 2-bromomethyl-3-nitromethyl benzoate; (2) performing cyclization on the compound 1 and 3-aminopiperidine-2,6-dione hydrochloride under a solvent-free condition to generate a compound 2 3-(4-nitro-1-oxo-1,3-dihydroisoindole-2-yl)piperidine-2,6-dione; and (3) reducing the compound 2 with a reducing agent to obtain lenalidomide. According to the invention, the method is a novel preparation process method of lenalidomide, and has advantages of easily available process raw materials, short steps, simple and convenient operation, environmental friendliness, implementation value of industrial production, and social and economic benefits.

Owner:TIANJIN RUILING CHEM CO LTD

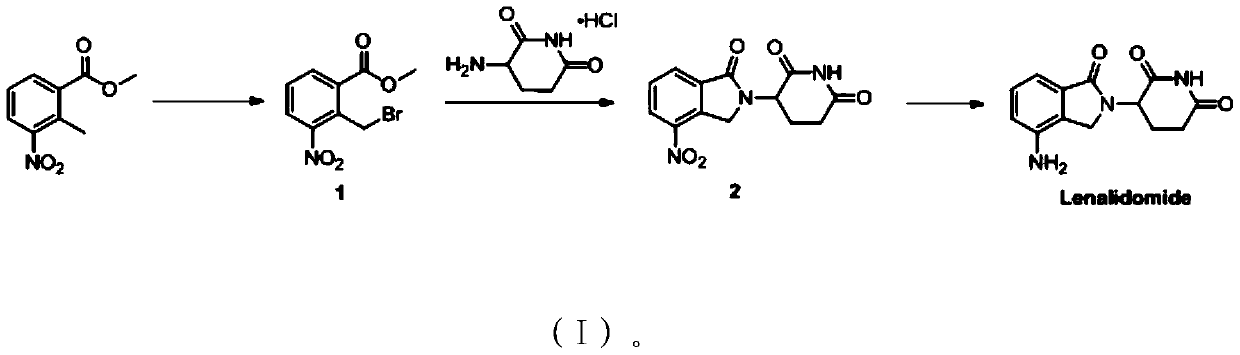

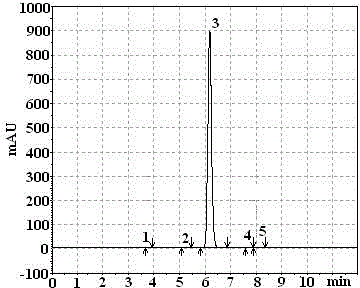

Method for synthesizing (4-hydroxyphenyl) methyl benzyl sulfonium hexafluoroantimonate

InactiveCN105541686AHigh purityMeet large-scale industrial productionSulfide preparationPotassium iodinePotassium carbonate

The invention relates to a method for synthesizing (4-hydroxyphenyl) methyl benzyl sulfonium hexafluoroantimonate. The method includes the following steps that in a solvent, 4-mercaptophenol or benzyl chloride or benzyl bromide serves as a raw material, and 4-(benzylthio) phenol is prepared under the action of triethylamine or potassium carbonate or sodium carbonate; in a toluene or cyclohexane or chloroform or dichloroethane solution, 4-(benzylthio) phenol and dimethyl sulfate or potassium iodide are methylated to obtain (4-hydroxyphenyl) methyl benzyl sulfonium sulfate or (4-hydroxyphenyl) methyl benzyl sulfonium iodate; in a methanol or alcohol or isopropanol solution, (4-hydroxyphenyl) methyl benzyl sulfonium sulfate and sodium hexafluoroantimonate are subjected to ion exchange to obtain the target product (4-hydroxyphenyl) methyl benzyl sulfonium hexafluoroantimonate. The method has the advantages that the raw materials are easy to obtain, the technology is simple, the prepared 4-(benzylthio) phenol is high in purity and does not need to be refined, and the requirement for large-scale industrial production of (4-hydroxyphenyl) methyl benzyl sulfonium hexafluoroantimonate can be met.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Synthetic method of propyzamide

ActiveCN103242190BImprove securityHigh purityPreparation from carboxylic acid saltsOrganic compound preparationBenzoic acidBiochemical engineering

The invention discloses a synthetic method of propyzamide. The method comprises the following steps: by taking 3, 5-dichlorobenzoic acid as a raw material, chlorinating 3, 5-dichlorobenzoic acid to generate 3, 5-dichlorobenzoyl chloride; further performing reaction between generated 3, 5-dichlorobenzoyl chloride and 3-amino-3-methyl butyne in the presence of alkaline matters and solvents; and filtering, drying and recrystallizing the reaction solution to obtain propyzamide. The material in the process is easy to obtain and low in cost, the production cost of products is low, and the safety coefficient of the process is high. The method is simple to operate, short in process flow and beneficial for industrialized production, and is a novel process for synthesizing propyzamide.

Owner:SHANDONG WEIFANG RAINBOW CHEM

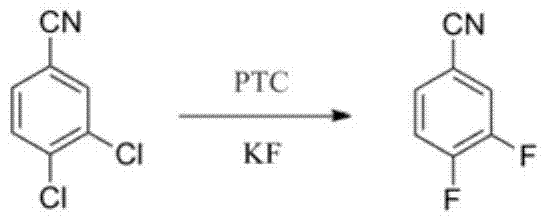

A kind of synthesis technique of 3,4-difluorobenzonitrile

ActiveCN103539699BProcess raw materials are easy to getShort reaction timeCarboxylic acid nitrile preparationOrganic compound preparationPotassium fluorideChloride

The present invention disclosed a synthetic process of 3,4‑ ylfluorophenpine, with 3,4‑ ‑ 腈 腈 as the raw material, potassium fluoride is a fluoride reagent, and 1,3‑ 甲 咪 咪 2‑ pyramoleAntinone is a response solvent. Double ‑ (N -two (diharamine) sore) chloride salt is catalyst. The reactor reacts from 130 to 150 ° C for 2 to 3h, and the reaction of 180 ° C ° C is 5 ~ 5 ~At the end of 6h, the reactive decompression and refined distillation of 3,4‑ ‑ylfluorophenillene, which was purified after filtering the reaction solution, reached 85%.Terminal liquid (including catalyst) is directly used for the next batch of reactions.The material raw materials of the present invention are easy to obtain, the response conditions are mild, the response time is short, the operation is simple, the yield is high, the reaction solvent (including catalyst) can be applied multiple times, the cost is low, the three waste discharge is small, and it is suitable for industrial production.

Owner:SHANGHAI HUAYI GRP CO

Synthesis of vitamin D2 derivatives

InactiveCN107488191AHigh yieldProcess raw materials are easy to getGroup 4/14 element organic compoundsTacalcitolPollution

The invention discloses a synthetic method for vitamin D2 derivatives. The synthesis of the key intermediate C-24 hydroxyl group for the commercially-available drugs tacalcitol and calcipotriol is basically prepared by using a NaBH4 reduction method. The NaBH4 reduction method has the disadvantages that target product yield is about 50% and the byproduct C-24 hydroxyl epimer alcohol has no value in use. According to the invention, a byproduct 1 or a byproduct 4 respectively produced in preparation of tacalcitol or calcipotriol is used as a starting material, a Dess-Martin reagent is used as an oxidation reagent, and a reaction is carried out in an organic solvent at 0 DEG C to 100 DEG C; after the reaction is completed, cooling to room temperature is carried out and then treatment is carried out so as to obtain an intermediate 2 or 5, respectively; and after treatment, the intermediate 2 or 5 is subjected to a reduction reaction so as to obtain a compound 3 or 6, respectively. Compared with the prior art, the synthetic method provided by the invention has the advantages that raw materials are easily available; reaction conditions are mild; post-treatment is simple; the utilization rate of atoms is increased; and pollution is reduced.

Owner:JIANGSU JIBEIER PHARMA

New method for synthesizing milrinone

The invention discloses a new method for synthesizing milrinone. The method is characterized in that a compound of formula 3 and 4-pyridineboronic acid undergo a Suzuki coupling reaction to synthesize milrinone. The method has the advantages of easily available raw materials, high yield and simple post-treatment.

Owner:HUNAN SAILONG PHARMA

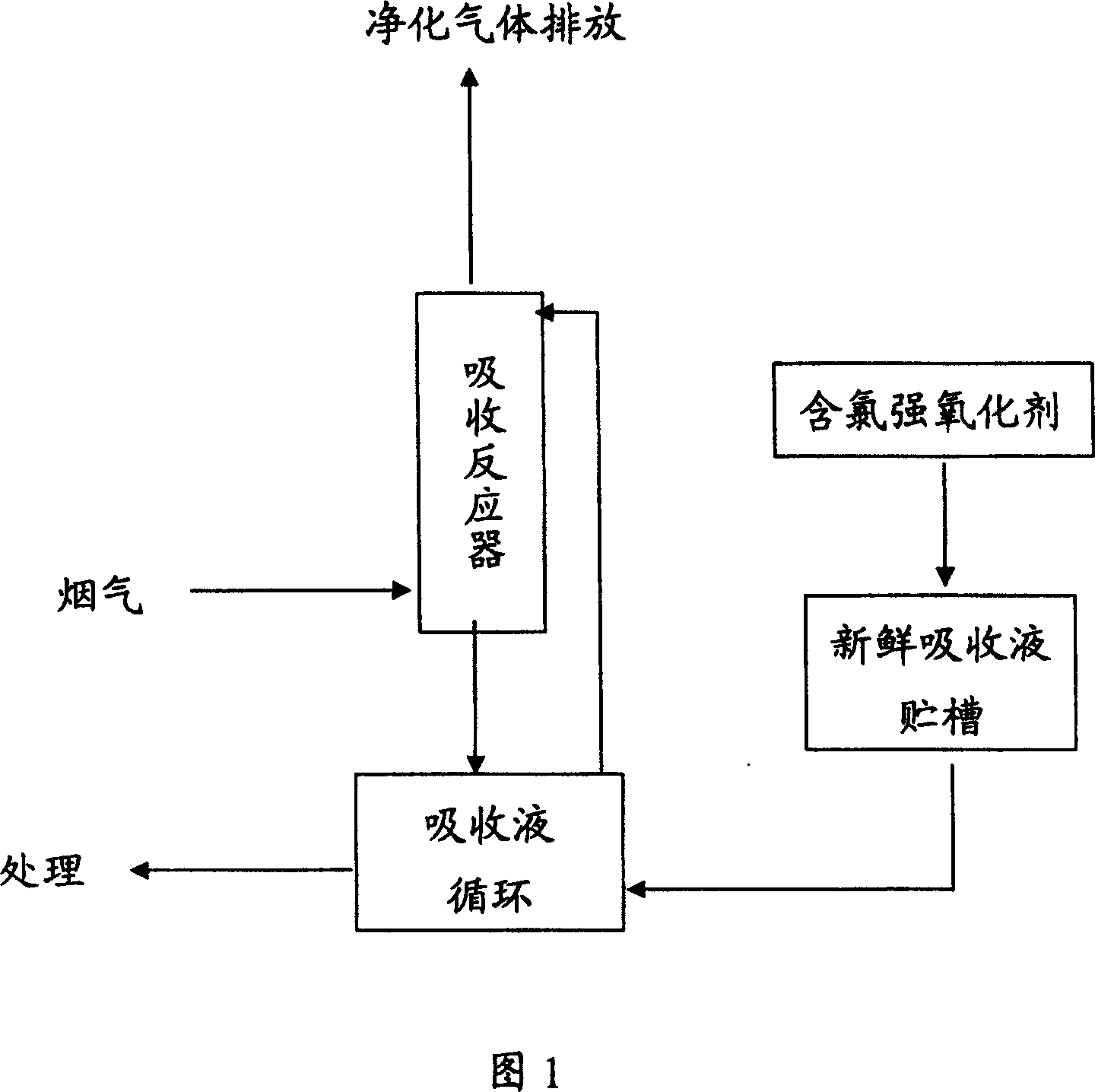

Wet method combined process for desulfurization and denitration for chlorine-containing strong oxidizer absorption liquid

InactiveCN100366325CProcess raw materials are easy to getLow costDispersed particle separationAir quality improvementFlue gasPhysical chemistry

The invention discloses a process for wet method simultaneous desulfurization and denitration by using chlorine-containing strong oxidizer absorption liquid, comprising: infusing flue gas to be processed into absorption reactor to fully contact with chlorine-containing strong oxidizer absorption liquid, absorbing NOx and SO2 in flue gas and discharging same. In the invention, the raw materials are easy to obtain, and the formulation of adsorption liquid is easy. For processed flue gas by the above process, removal efficiency of nitric oxides can be up to 60 to 95%, and the desulfurization efficiency can be up to more than 90%.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

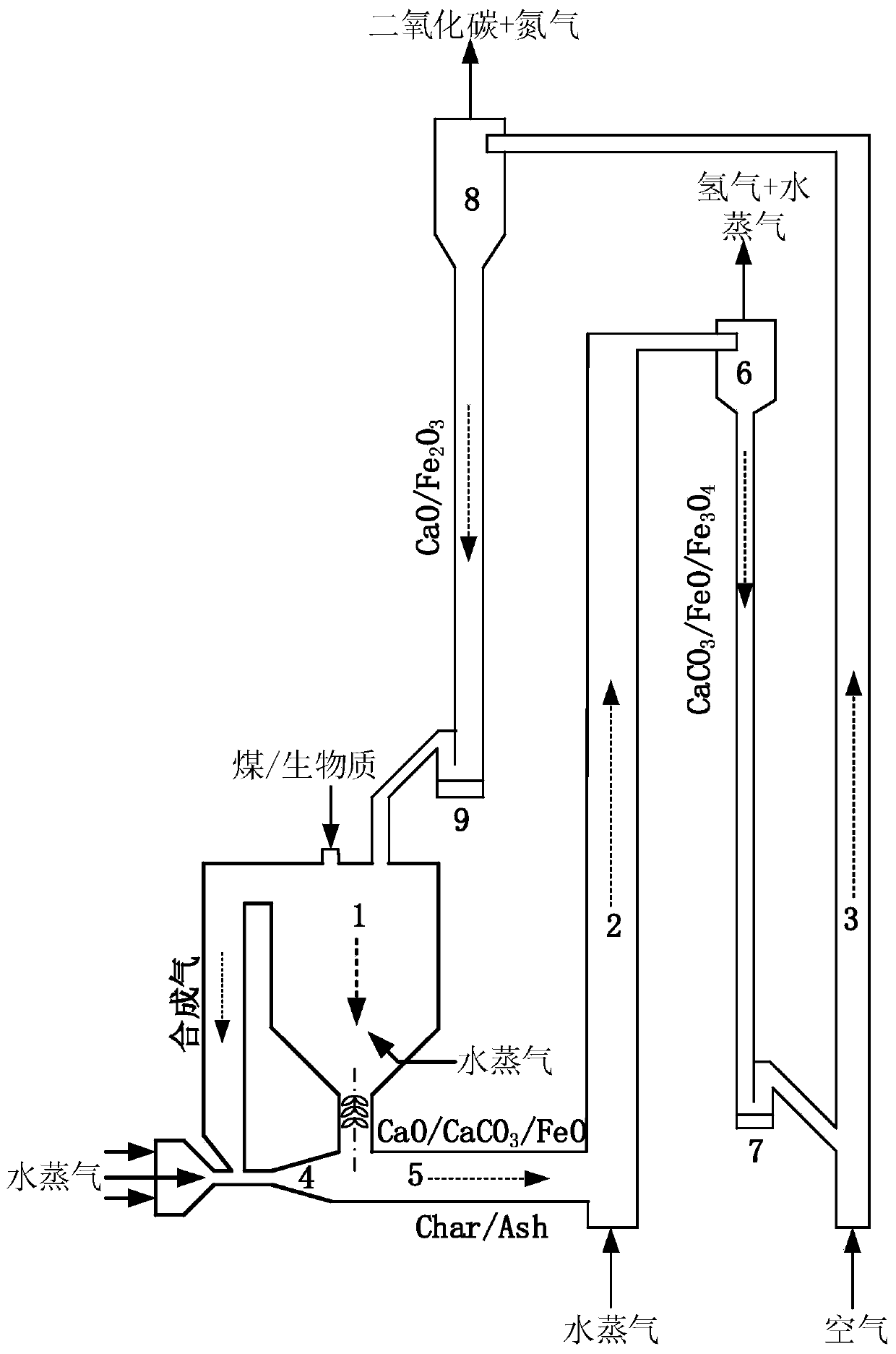

Device and method for preparing hydrogen through coal/biomass chemical-looping gasification

ActiveCN110964570ASimple device structureEasy to operateGas treatmentDispersed particle separationChemistryIron oxide

The invention discloses a device and a method for preparing hydrogen through coal / biomass chemical-looping gasification. According to the method, coal / biomass particles enter from the upper portion ofa moving bed gasification furnace, and are mixed with a circulating bed material containing calcium oxide and ferric oxide, water vapor is introduced into the gasification furnace, and pyrolysis andgasification reaction are performed to generate synthesis gas; the water vapor as an ejection gas flow enters a steam reactor along with the gasified coke and the bed material particles, and hydrogenis generated through a joint reaction with the water vapor in the steam reactor; the bed material enters an air reactor and is oxidized or decomposed, and the oxidized material or decomposed materialenters the gasification furnace again; hydrogen, carbon dioxide and nitrogen can be obtained from gas separated out of two cyclone separators; and the bed material particles continuously participate in an oxidation reduction or carbonization decomposition reaction and are recycled. The device is simple in structure, convenient to operate, scientific in process raw material, easy in raw material obtaining, low in cost, high in carbon utilization efficiency, less in pollutant and environment-friendly.

Owner:SOUTHEAST UNIV

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479BHeat-resistant and anti-yellowingLattice stabilizationPigment treatment with organosilicon compoundsPigment physical treatmentSlurryRutile

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

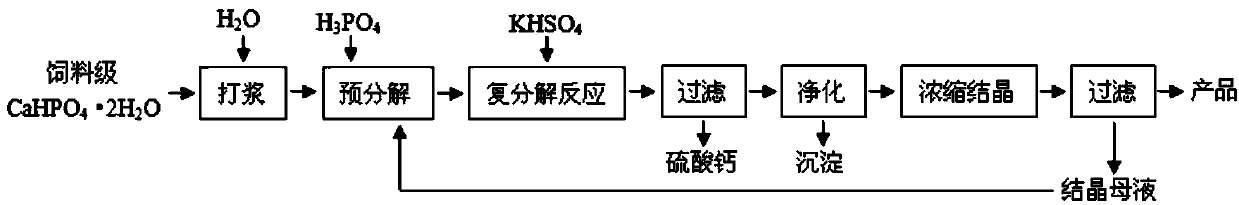

A kind of method of producing potassium dihydrogen phosphate

ActiveCN106744764BHigh recovery rateAchieve recyclingPhosphorus compoundsHydrogen SulfateHydrogen phosphate

The invention relates to a monopotassium phosphate production method. Feed-grade calcium hydrogen phosphate and industrial-grade phosphoric acid are firstly subjected to a pre-decomposition reaction, potassium hydrogen sulfate is added for a double-decomposition reaction, calcium sulfate and filtrate are filtered out, the filtrate is purified, concentrated, cooled and crystallized, a monopotassium phosphate product is prepared, crystallization mother liquor returns to feed-grade calcium hydrogen phosphate for cyclic operation or is used in production of chloride-free compound fertilizer. Compared with the prior art, the recovery rate of phosphorus in feed-grade calcium hydrogen phosphate is substantially increased to 95% or above through pre-reaction of phosphoric acid and feed-grade calcium hydrogen phosphate, besides, the yield of potassium in potassium hydrogen phosphate reaches 99.5%, meanwhile, phosphoric acid is recycled, emission of waste liquor is avoided, the technological process is simple, the yield of phosphorous and potassium in raw materials is high, the production cost can be substantially reduced, and the method is environment-friendly and sustainable and has great competitive advantages.

Owner:EAST CHINA UNIV OF SCI & TECH +1

High-dispersed titanium pigment and its production

InactiveCN100482748CGood water dispersibilityHigh hiding powerInorganic pigment treatmentSal ammoniacWater dispersible

A titanium pigment and its production are disclosed. Anatase titanium dioxide content is <99% and water dispersion is <92% and emulsified dispersant 0.1-0.4% is added. It's simple and cheap, less consumption, excellent coating covering powder and mechanical performance. It's convenient for transportation and storage.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

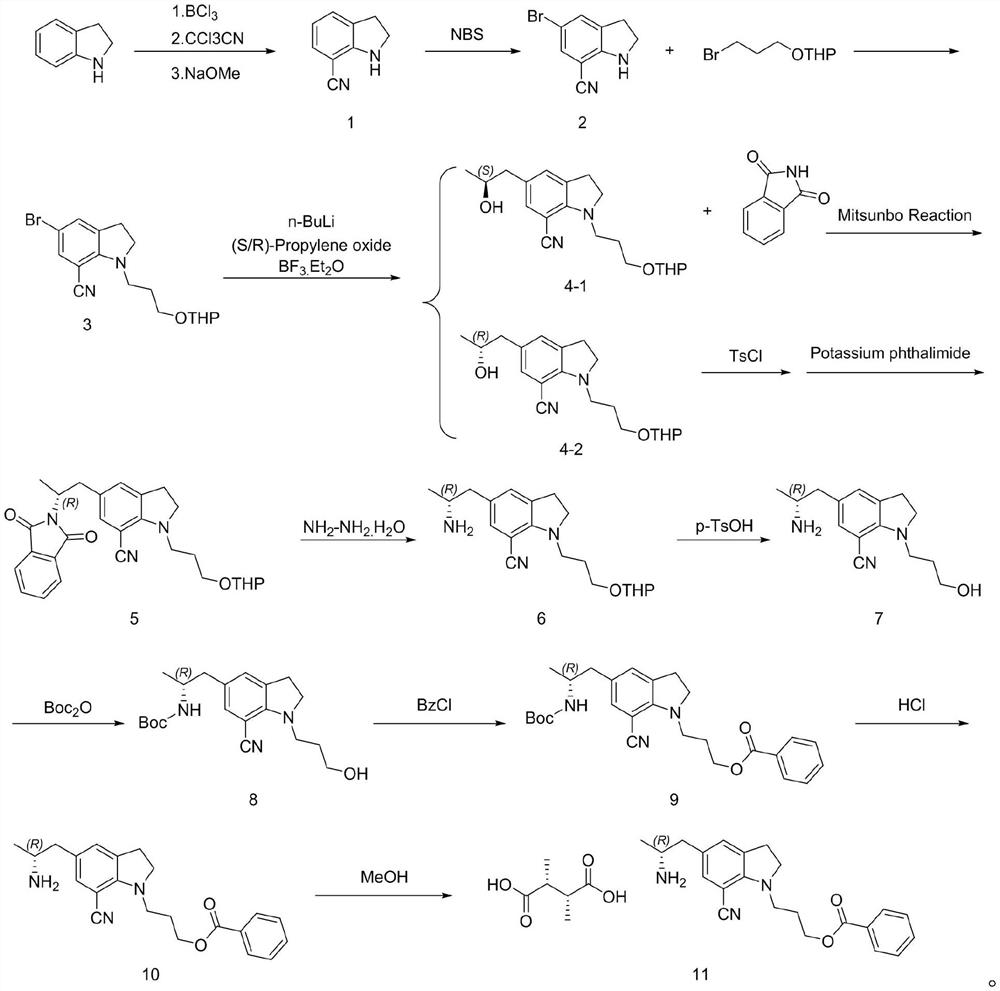

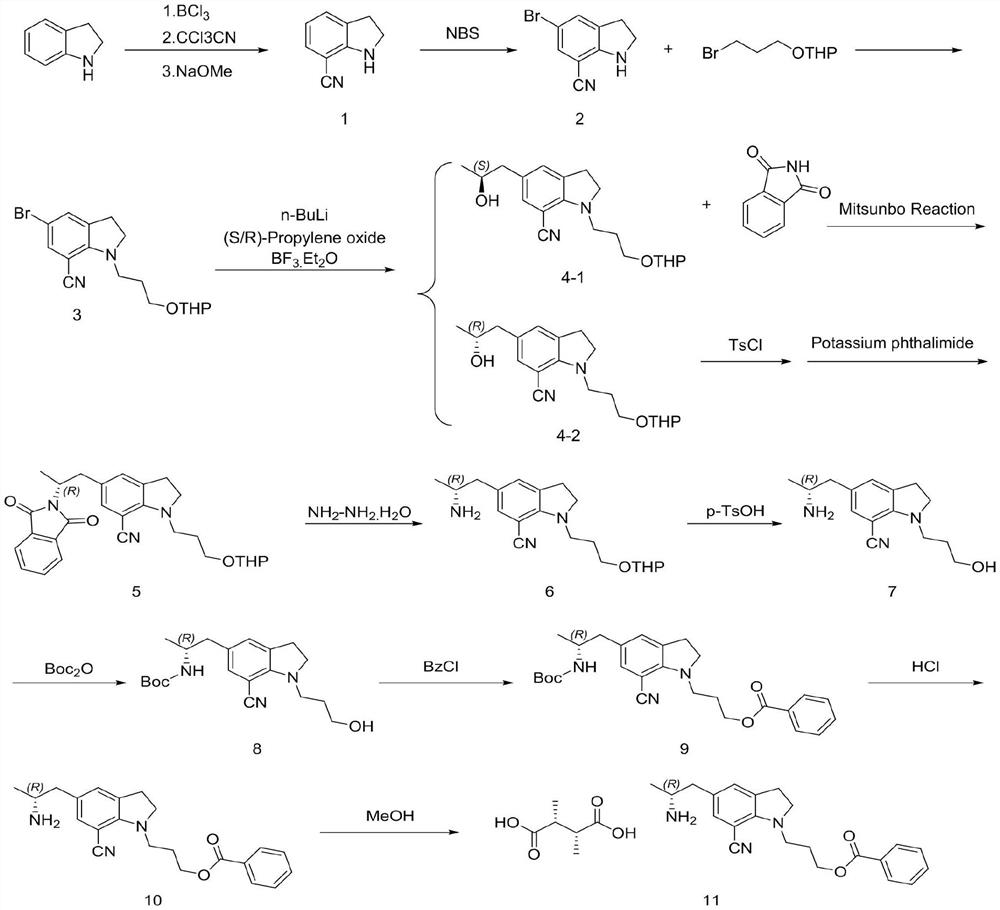

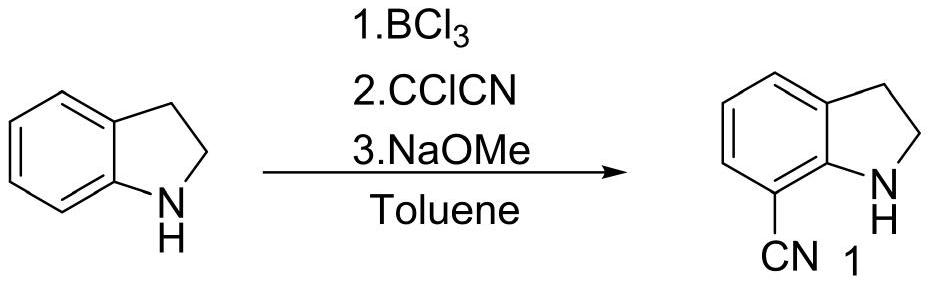

Preparation method of silodosin key intermediate

PendingCN114751852ASplit atom utilization is lowReduce utilizationOrganic compound preparationCarboxylic acid salt preparationTrichloroacetonitrilePyran

The invention discloses a preparation method of a silodosin key intermediate, and belongs to the technical field of medicine synthesis. Carrying out Friedel-Crafts reaction on indoline and trichloroacetonitrile to obtain a compound 1; brominating to obtain a compound 2; then carrying out substitution with 2-(3-bromopropoxy) tetrahydro-2H-pyran to obtain a compound 3; then carrying out nucleophilic addition with (S)-epoxypropane or (R)-epoxypropane at an ultralow temperature to obtain a compound 4; then carrying out Mitsunobu reaction with phthalimide to obtain a compound 5 (configuration inversion) or esterifying with paratoluensulfonyl chloride, and reacting with potassium phthalimide under the condition of inorganic alkali to obtain the compound 5; reducing through hydrazine hydrate to obtain a compound 6; then removing tetrahydropyran protection from p-toluenesulfonic acid to obtain a compound 7; performing amino Boc protection under an alkaline condition to obtain a compound 8; esterifying with benzoyl chloride to obtain a compound 9; removing Boc protection with hydrochloric acid to obtain a compound 10; and salifying with L-tartaric acid to obtain a compound 11. Compared with the prior art, the preparation method has the advantages that cyano groups synthesized by Vilsmeier reaction, hydroxylamine oximation and acetic anhydride dehydration at the 7 site and introduction of amino groups at the 5 site through nitro groups or reductive amination are avoided, and heavy metals such as Pd / Pt / Zn and the like do not need to be used; the continuous operation of the whole steps is increased, the production cost of the silodosin intermediate is greatly reduced, and industrial large-scale production is facilitated.

Owner:山西库邦生物医药科技有限公司

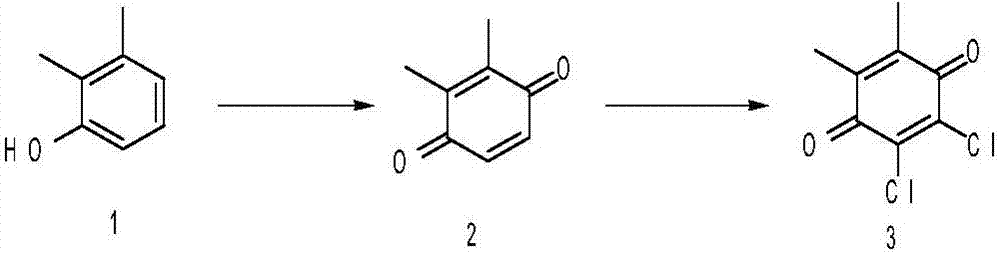

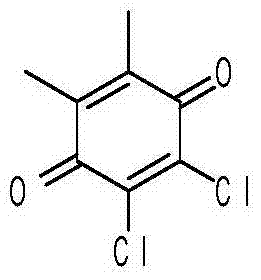

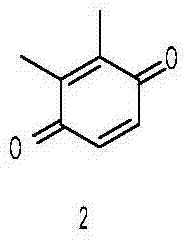

Novel method for preparing cinnoline derivative midbody dichloro dimethyl benzoquinone

InactiveCN103787849AProcess raw materials are easy to getShort stepsOrganic compound preparationQuinone preparation by oxidationBenzoquinoneChemistry

The invention relates to a cinnoline derivative midbody, in particular to a novel method for preparing cinnoline derivative midbody dichloro dimethyl benzoquinone. 2, 3-xylenol is adopted as starting raw materials in the method, and target compounds are obtained through oxidization and chlorination.

Owner:湖南华腾制药有限公司

Production method for environmental-friendly low-temperature-resistant antiflaming compound plasticizer

The invention discloses a production method for environmental-friendly low-temperature-resistant antiflaming compound plasticizer. The production method comprises the following steps: (1) preparing a plasticizer matrix: 1) esterification, 2) purification, 3) filter pressing purification, and 4) distillation; (2) preparing a low-temperature-resistant antiflaming system: evenly mixing nanosilicon dioxide, gas phase method silica aerogel, methyl hydrogen silicone oil, hydroxyl polydimethylsiloxane, vinyl trimethoxy silane, ammonium polyphosphate, reactive diluent, compatilizer, coupling reagent, flatting agent and mixed rare earth chloride at a ratio; (3) preparing the environmental-friendly low-temperature-resistant antiflaming compound plasticizer: evenly mixing the plasticizer matrix and the low-temperature-resistant antiflaming system obtained in the steps, wherein the addition of the low-temperature-resistant antiflaming system is 1.7-1.9wt% of the plasticizer matrix. The plasticizer has the advantages of good environmental protection property, high plastification efficiency, low temperature resistance, extremely low volatility and good stability.

Owner:JIANGSU SENHE CHEM TECH CO LTD

Environment-friendly low-temperature-resistant fire-retardant complex plasticizer

InactiveCN106589466APromote environmental protectionHigh plasticizing efficiencyOrganic compound preparationCarboxylic acid esters separation/purificationAlcoholPlasticizer

The present invention discloses an environment-friendly low-temperature-resistant fire-retardant complex plasticizer, comprising a matrix of the plasticizer, the matrix is prepared from sebacic acid, decyl alcohol, a catalyst, sodium carbonate and an auxiliary by exetrification, refining, filter-press refining and distilling. The weight ratio of sebacic acid to decyl alcohol is 1 to 1.57-5. The adding amount of the catalyst is 0.2-1% of the total weight of sebacic acid and decyl alcohol, the adding amount of sodium carbonate is 0.1-0.7% of the total weight of sebacic acid and decyl alcohol and the adding amount of the auxiliary is 0.3-1% of the total weight of sebacic acid and decyl alcohol. The plasticizer also comprises a low-temperature-resistant fire-retardant system. The plasticizer disclosed by the invention has the advantages of great environmental friendliness, high plasticizing efficiency, low-temperature resistance, low volatility, extremely low volatility and great stability.

Owner:JIANGSU SENHE CHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com