Preparation method and applications of AgBr/g-C3N4 composite powder

A composite powder, g-c3n4 technology, used in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of narrow spectral response range, limited use range, low quantum efficiency, etc. Response range, improved photocatalytic activity, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

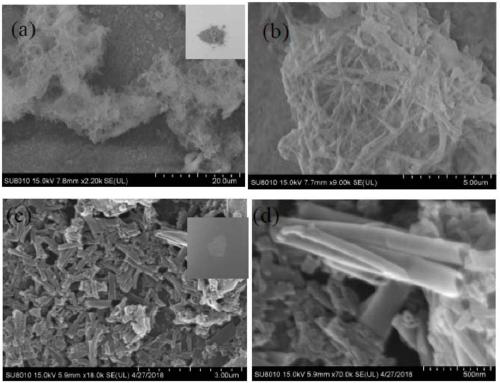

[0031] g-C 3 N 4 The preparation was divided into two groups of experiments, the difference between the two was only that the reaction time was 36h and 48h respectively, and the other process steps were exactly the same. Specific steps are as follows:

[0032] ①. Weigh 0.554g of cyanuric chloride, 0.189g of melamine and 0.2g of urea into a beaker, measure 15mL of acetonitrile reagent into the beaker, and stir with a glass rod for 5min to disperse;

[0033] ②. After the stirring is completed, pour the mixture into a 25mL reaction kettle, cover the reaction kettle and put it into a constant temperature blast oven, set the temperature at 180°C, and the reaction time is 36h and 48h respectively;

[0034] ③. After the reaction is completed, take out the reaction kettle, put the reaction substance in the reaction kettle into a 15mL plastic test tube; centrifuge with a centrifuge, and then wash 3 times with deionized water and absolute ethanol;

[0035] ④. Put the washed material ...

Embodiment 2

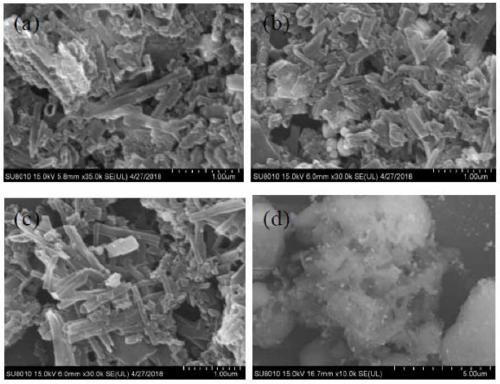

[0039] AgBr / g-C 3 N 4 Preparation of composite powder

[0040] Due to the lower success rate of rod-shaped carbon nitride, less yield, poorer dispersion than tubular carbon nitride and uneven appearance, tubular nitrogen was selected in the preparation process of composite powder and subsequent photocatalytic performance testing. Carbonized carbon (reaction time is 36 hours) is used as experimental raw material.

[0041] AgBr / g-C 3 N 4 The composite powder was prepared by ultrasonic method, using CTAB as a surfactant, using silver nitrate to provide silver ions, and changing AgBr and g-C 3 N 4 The mass ratio of AgBr is used to synthesize composite powders of different proportions. The mass fractions of AgBr are 5%, 10%, 15%, and 20%, respectively, and the samples shown in Table 1 are prepared accordingly; the following composite powder mass is 0.2 g, the preparation method steps are as follows:

[0042] ①. Weigh g-C 3 N 4 , silver nitrate, and CTAB are placed in a bea...

Embodiment 3

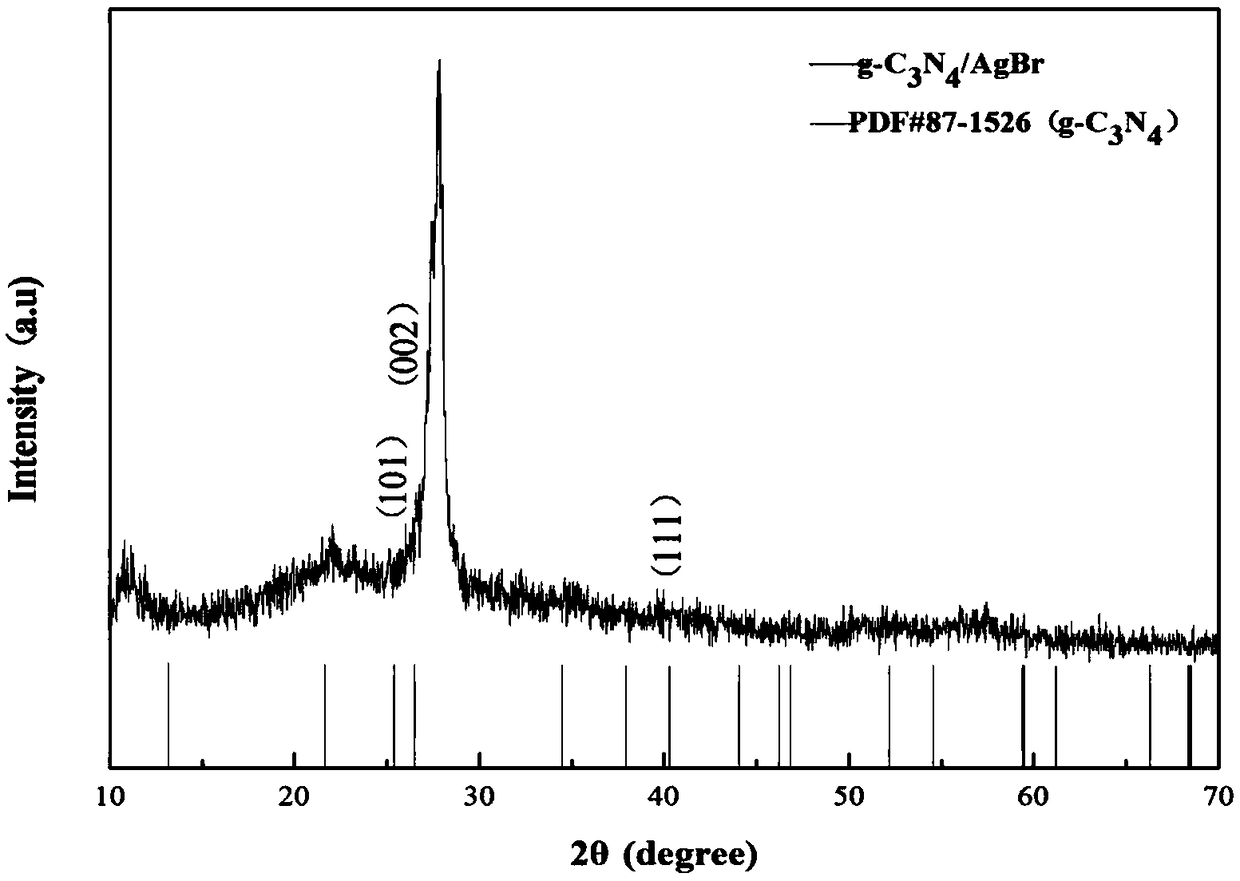

[0052] For tubular g-C 3 N 4 And the AgBr / g-C prepared by using tubular carbon nitride with AgBr loading of 20% 3 N 4 The composite powder was analyzed for crystal form. image 3 for g-C 3 N 4 XRD pattern. with C 3 N 4 Compared with the standard card PDF#87-1526, it can be seen that g-C appeared at 25.396°, 26.504°, and 40.303° respectively 3 N 4 The (101), (002), (111) diffraction peaks indicate that the prepared powder sample is carbon nitride.

[0053] Figure 4 is AgBr / g-C 3 N 4 XRD pattern. Compared with the standard card PDF#79-0149 of AgBr, it can be seen that the prepared AgBr / g-C 3 N 4 The composite powder has (111), (200), (220), (222) diffraction peaks at 26.715°, 30.944°, 44.328°, and 55.039° respectively, and the diffraction peaks are sharper, indicating better crystallinity. In the XRD spectrum of the prepared composite powder, the complete silver bromide diffraction peak can be clearly seen, and the diffraction peak of carbon nitride at 26.716° o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com