Device and method for preparing hydrogen through coal/biomass chemical-looping gasification

A biomass and chemical chain technology, applied in the direction of chemical instruments and methods, granular/powdered fuel gasification, gasification process, etc., can solve problems such as direct hydrogen production that is not applicable to coal/biomass conversion, and achieve low cost, Environmentally friendly and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

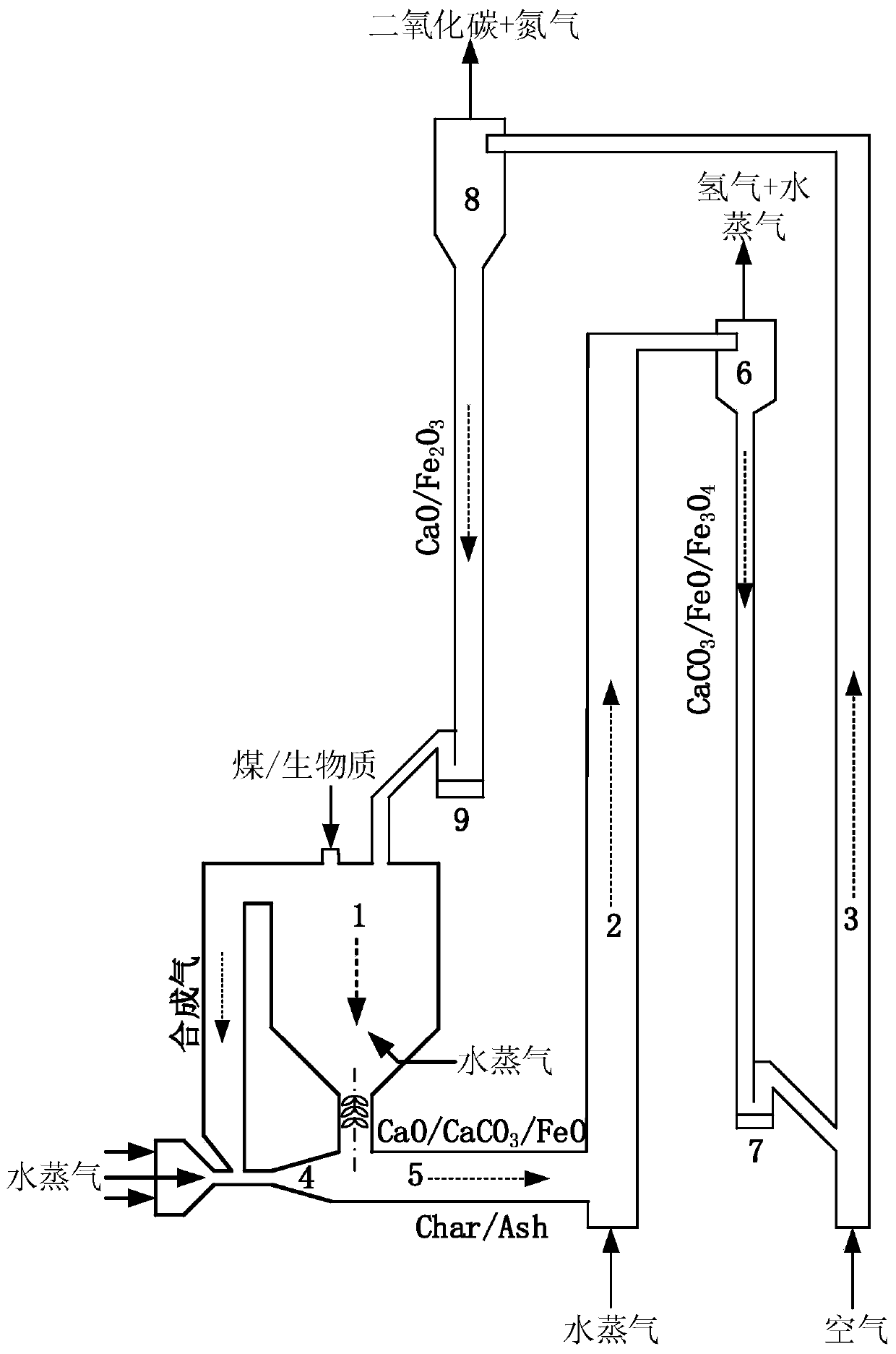

[0027] The main structure of the device described in this embodiment includes a moving bed gasifier, a gas injection device, a material conveying device, a steam reactor, a first gas-solid separation device, a first flow control device, an air reactor, a second gas Solid separation device, second flow control device; wherein, coal / biomass particles enter the moving bed gasifier, and after drying, pyrolysis and gasification reactions, coke particles and ash particles are produced, along with calcium oxide and ferrous oxide The circulating bed material particles enter the steam reactor, and the synthesis gas generated in the gasifier passes through the gas injection device, enters the material conveying device, and carries the above particles into the steam reactor; the steam reactor is a fluidized bed, and the bottom There is an air distribution plate, and its flow pattern is a fast fluidized bed / pneumatically conveyed bed flow pattern, and the fluidization medium is water vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com